The differences between Silicon Nitride Ceramic Substrate and Aluminum Nitride Ceramic Substrate

With the rise and use of electronic device especially the Third generation semiconductors,Semiconductor devices are more and more miniaturized, integrated and multifunctional, higher demands are requested in property of substrate capsulation. Ceramic substrates are widely used in electronic device capsulation because of high thermal conductivity and heat resistance, low coefficient of thermal expansion, high mechanical and insulation strength,corrosion resistance and radioresistance.

more and more miniaturized, integrated and multifunctional, higher demands are requested in property of substrate capsulation. Ceramic substrates are widely used in electronic device capsulation because of high thermal conductivity and heat resistance, low coefficient of thermal expansion, high mechanical and insulation strength,corrosion resistance and radioresistance.

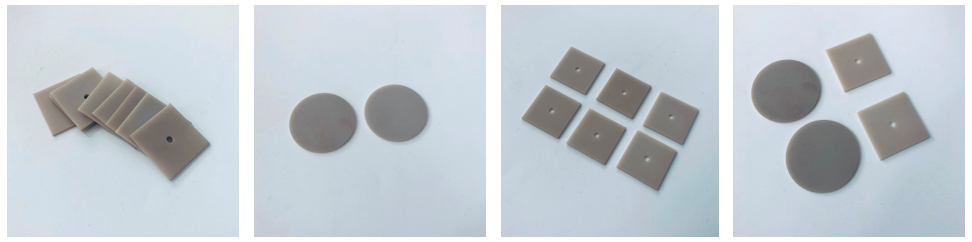

Due to excellent hardness, mechanical strength and heat dissipation, both silicon nitride ceramic and aluminum nitride ceramic can be produced into ceramic substrates which are used for electronic capsulation, meanwhile, they are also different in properties and advantages. Here is the difference below.

1. Difference in heat dissipation

The thermal conductivity of silicon nitride ceramic substrate is 75—80W/(m·k), while the aluminum ceramic substrate is above 170 W/(m·k).It is obviously that the aluminum nitride ceramic substrate is advantaged.

2. Difference in electricity capacity

The electricity capacity of silicon nitride ceramic substrate is 300A, and the aluminum ceramic substrate is 100-300A.

3. Difference in mechanical strength

Silicon nitride ceramic substrate has better fracture toughness than aluminum nitride ceramic substrate, so it’s not easily to be broken. Also, Silicon nitride ceramic substrate has higher flexural strength. Flexural strength of aluminum nitride ceramic substrate is 365-420Mpa, silicon nitride ceramic substrate is 720Mpa. Meanwhile, silicon nitride ceramic substrates have higher hardness and better wear resistance. This will improve the mechanical strength and impact resistance, make the substrates more reliable.

4. Difference in application

Based on the property differences between silicon nitride ceramic substrate and aluminum nitride ceramic substrate, they are used to different areas. Aluminum nitride ceramic substrate is more suitable for high thermal conductivity, high insulating and large current applications. Such as high-power heat conduction device, high power led module, semiconductor module circuitry and so on.With high mechanical strength and good heat conduction, silicon nitride ceramic substrate is always applied in products of high strength, low density and good wear resistance. For example, the auto inverter, reducer and shock absorber.