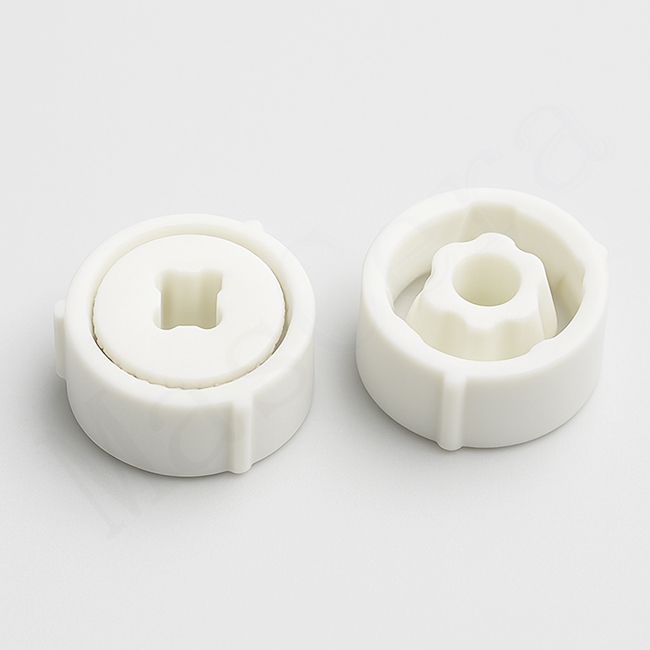

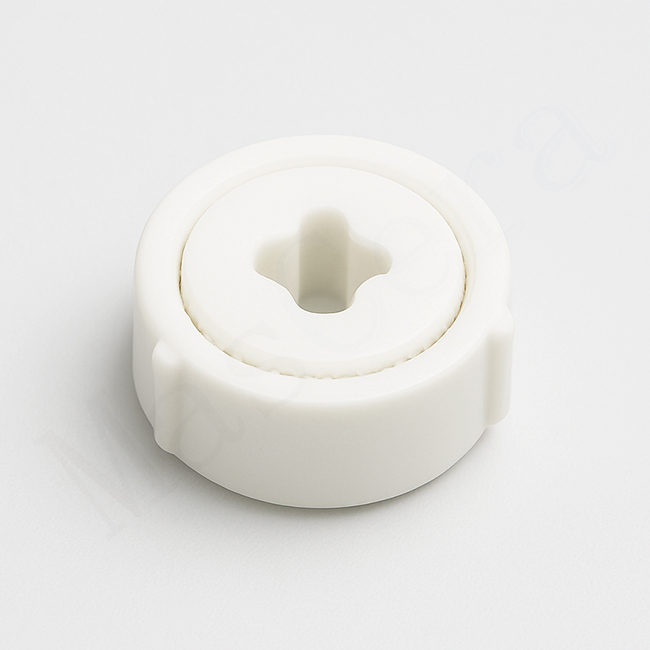

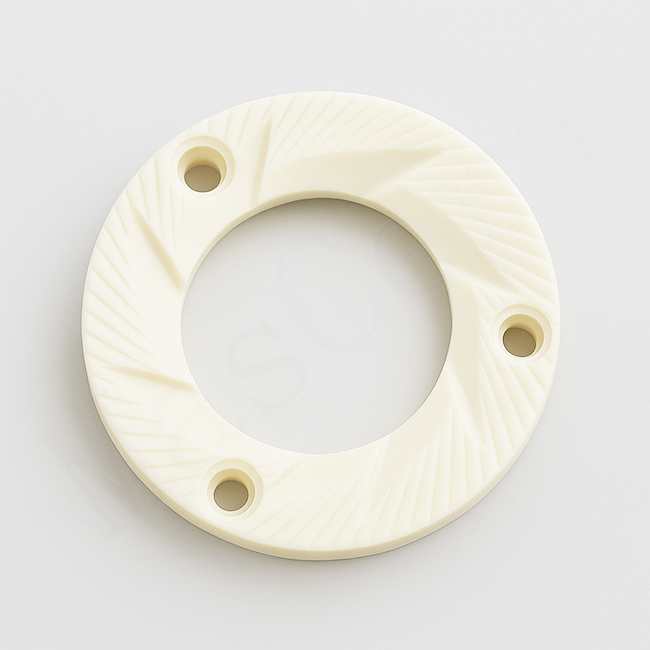

Ceramic Grinding Core for Coffee and Seasoning Applications

- MSJ/AL-016

- Alumina Ceramic

- customized

- 100

- Coffee and Seasoning Applications

Mascera’s Ceramic Grinding Core products, made from high-purity alumina (≥95% Al₂O₃) or steatite, are engineered to deliver excellent hardness, precision, and food safety in grinding applications. Whether used in a coffee grinder, pepper mill, or seasoning grinder, our Ceramic Grinding Core solutions ensure consistent performance in high-intensity, long-term food processing environments.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product Detail

Mascera's Ceramic Grinding Core products, made from high-purity alumina (≥95% Al₂O₃) or steatite, are engineered to deliver excellent hardness, precision, and food safety in grinding applications. Whether used in a coffee grinder, pepper mill, or seasoning grinder, our Ceramic Grinding Core solutions ensure consistent performance in high-intensity, long-term food processing environments.

Key Features

High Hardness & Wear Resistance

Each Ceramic Grinding Core is made from carefully selected Wear Resistant Ceramic materials such as alumina or steatite. With a Mohs hardness close to 9, our cores retain sharp grinding surfaces and resist mechanical wear over long periods of use.

Corrosion & Heat Resistance

As chemically stable Wear Resistant Ceramic materials, both alumina and steatite resist acid, alkali, moisture, and high temperatures. The Ceramic Grinding Core maintains performance even in hot or humid grinding environments, ensuring food flavor integrity.

Food Contact Safety

All materials used in our Ceramic Grinding Core are certified by FDA, LFGB, and EEC for food safety. These Wear Resistant Ceramic cores eliminate concerns over rust, heavy metal leaching, or microplastics, making them ideal for kitchen tools and food processing equipment.

Consistent Particle Size

Whether the structure is conical or flat, the Ceramic Grinding Core delivers uniform grinding performance. This is particularly important in coffee grinding and spice processing, where consistency impacts flavor and texture.

Eco-Friendly & Long Lifespan

Compared to metal or plastic alternatives, our Ceramic Grinding Core systems made from Wear Resistant Ceramic require fewer replacements, offer better recyclability, and reduce long-term costs for customers.

Material Options

Mascera offers two main types of Wear Resistant Ceramic for Ceramic Grinding Core manufacturing:

95% Alumina Ceramic

Used in reusable and refillable grinders, this Wear Resistant Ceramic offers superior hardness, thermal resistance, and mechanical strength. It’s the ideal material for high-performance Ceramic Grinding Core designs in premium equipment.

Steatite Ceramic

A cost-effective alternative suitable for disposable grinders. While slightly lower in strength, this Wear Resistant Ceramic still offers solid performance and clean grinding results in one-time-use applications.

Both options are Wear Resistant Ceramic materials engineered for precise and stable operation across all grinding categories.

Application Scenarios

Mascera’s Ceramic Grinding Core components are widely used in:

Disposable Seasoning Grinders

One-Time Use Grinders

Reusable & Refillable Spice Grinders

Manual Hand Crank Coffee Grinders

Handheld Coffee Grinders

Automatic Coffee Machines & Makers

Whether your application is a kitchen appliance or an industrial grinder, our Ceramic Grinding Core solutions deliver performance and durability, backed by reliable Wear Resistant Ceramic engineering. These applications benefit from the temperature stability, hardness, and long wear life that only Wear Resistant Ceramic can provide.

Customization Services

Mascera provides full customization options for your Ceramic Grinding Core project:

Material Selection

Choose the right Wear Resistant Ceramic—alumina or steatite—for your intended application.

Structural Design

From flat to conical burrs, we design the optimal Ceramic Grinding Core geometry for your system.

Size & Tolerances

Customize outer diameter, inner shaft fit, and burr depth to your exact specifications.

OEM/ODM Service

We support brand-specific Ceramic Grinding Core development with end-to-end production solutions using only certified Wear Resistant Ceramic materials.

Why Mascera

With decades of experience in technical ceramics, Mascera is your trusted source for premium Ceramic Grinding Core components made from high-quality Wear Resistant Ceramic. We deliver:

Precise forming and sintering with Wear Resistant Ceramic control

Reliable grinding performance across diverse applications

Food-grade compliance and safety

Long service life and minimal maintenance

Competitive pricing and flexible MOQ

Contact us today to explore how Mascera's Wear Resistant Ceramic technology and Ceramic Grinding Core solutions can upgrade your grinding equipment and deliver lasting performance.