Metallized Ceramic Components for Hermetic Sealing and Electrical Applications

- MSJ/AL-015

- Alumina Ceramic

- Customizable

- 500 pieces per type

- Hermetic Sealing and Electrical Applications

Mascera applies Molybdenum-Manganese Metallization (Mo-Mn) as our standard process. A specially formulated Mo-Mn paste is screen-printed or coated onto ceramic surfaces and sintered at high temperature in a reducing atmosphere. This forms a dense, adherent metallized layer. To improve solderability and brazing behavior, a nickel coating is typically applied over the Mo-Mn layer.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product Detail

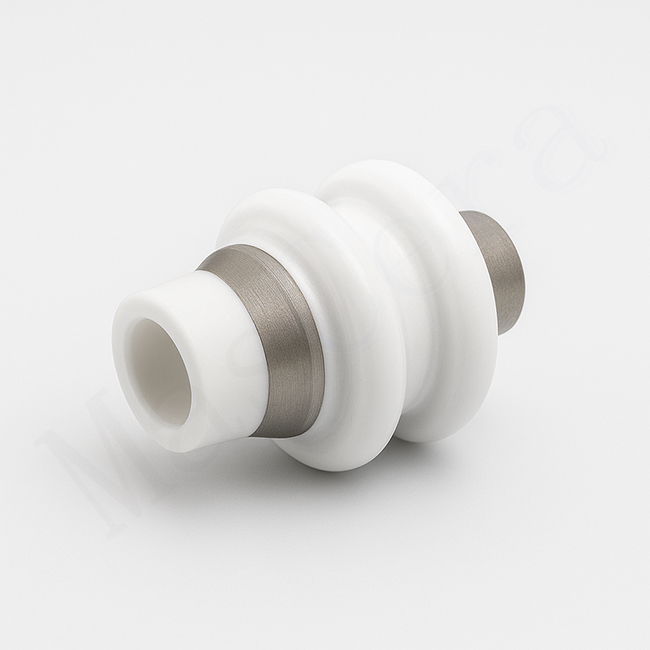

Mascera specializes in producing metallized ceramic (Molybdenum-Manganese Metallization) components using high-purity alumina ceramics with purity levels ranging from 95% to 99%. Alumina (Al₂O₃) is one of the most widely used advanced ceramic materials, valued for its excellent mechanical strength, high hardness, chemical stability, thermal resistance, and superior electrical insulation. These core properties make alumina especially well-suited for use in high-temperature, high-voltage, or corrosive environments.

In many critical applications—such as vacuum systems, power electronics, and medical device assemblies—alumina parts must be reliably joined to metal components. This is where ceramic metallization plays a vital role. Through ceramic metallization(Molybdenum-Manganese Metallization), selected ceramic surfaces are modified to exhibit metal-compatible characteristics, enabling strong bonding to metal housings or leads while retaining the ceramic's insulating and structural benefits.

Mascera applies Molybdenum-Manganese Metallization (Mo-Mn) as our standard process. A specially formulated Mo-Mn paste is screen-printed or coated onto ceramic surfaces and sintered at high temperature in a reducing atmosphere. This forms a dense, adherent metallized layer. To improve solderability and brazing behavior, a nickel coating is typically applied over the Mo-Mn layer.

Our portfolio of metallized ceramics includes rings, tubes, discs, headers, and various custom-shaped insulators. All bonding areas and mechanical interfaces are precisely machined to meet tight dimensional tolerances. We understand that in metallized ceramic components(Molybdenum-Manganese Metallization), both metallization quality and dimensional accuracy are critical. Every batch is rigorously tested for weldability, hermetic sealing, and mechanical strength—ensuring that our metallized ceramics meet industry performance standards.

Key Features

High-purity alumina (95–99%) with excellent dielectric and mechanical performanceTight Uniform ceramic metallization with controlled coating thickness and density.

Outstanding brazing strength and vacuum-tight performance.

Full support for custom geometries and high-precision tolerances.

Fast delivery for prototypes and volume production of metallized ceramic components.

Typical Applications

Feed-through insulators in vacuum and high-voltage equipment.

Headers and SCR housings in power semiconductor assemblies.

High-power receptacles for electrical connectors.

Insulating rings, tubes, discs, and structural cylinders.

Precipitator components in environmental systems.

Vacuum interrupters and hermetically sealed switches.

X-ray tube ceramics and hermetic windows for medical and imaging use.

With in-house expertise in ceramic metallization, machining, and inspection, Mascera delivers durable, high-performance metallized ceramic components for the most demanding industrial, medical, and electronic applications. Whether you require small-batch prototyping or high-volume production, our metallized ceramics offer a reliable and scalable solution for ceramic-to-metal integration challenges.

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |