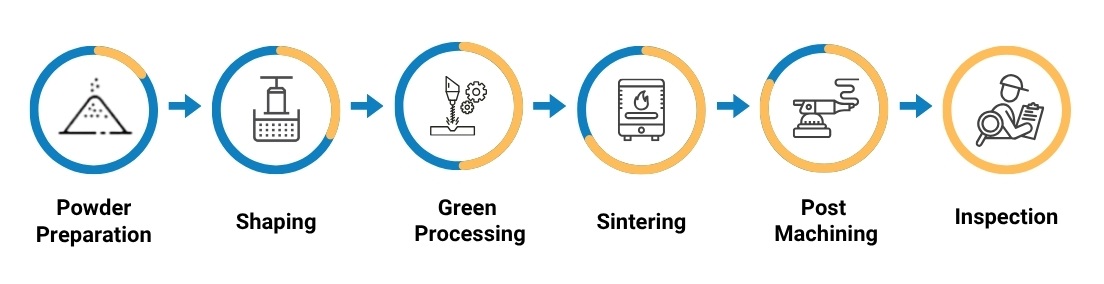

Manufacturing Capabilities

Custom Technical Ceramics – From Powder to Precision

At Mascera, we specialize in custom manufacturing of high-performance ceramic components. With fully integrated in-house capabilities, we control the entire production process—from raw powder shaping to precision finishing and functional surface treatment. This ensures superior quality, faster delivery, and reliable performance in every part we produce.

1.Powder Preparation Mascera begins every ceramic production with strict raw material selection and precise powder processing. We blend high-purity powders with additives through grinding, mixing, granulating, and drying to ensure consistent quality. This step directly affects the final performance of the ceramic and lays the foundation for stable forming and sintering in later stages. |

|

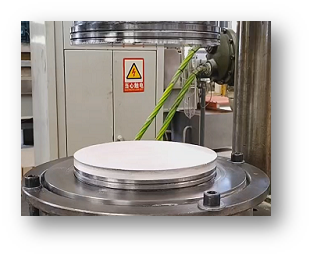

2.Shaping We employ various forming techniques tailored to the geometry, complexity, and application of each ceramic component: ◆ Dry Pressing Suitable for small, simple shapes; high efficiency and excellent dimensional consistency. ◆ Isostatic Pressing Ideal for large or complex shapes requiring uniform density and strength. ◆ Injection Molding Best for producing intricate, high-volume components. ◆ Tape Casting Used for thin ceramic sheets, substrates, and wafers. ◆ Slip Casting Preferred for large or hollow parts with consistent wall thickness. |

|

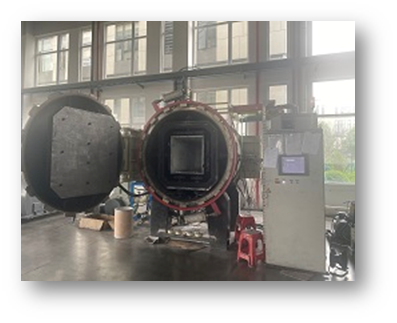

3.Sintering Processes To ensure material stability and high mechanical strength, we sinter ceramic components under controlled temperature and atmosphere: ◆ Protective Atmosphere Sintering ◆ Vacuum Sintering ◆ Hot Pressing Sintering Our shuttle kilns provide excellent temperature uniformity and precise firing control. |

|

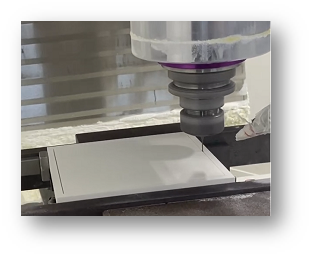

4.Precision Machining Capabilities Mascera offers advanced ceramic machining and finishing to meet the most demanding tolerance and surface requirements. Machining Accuracy◆ Linear tolerance: up to ±0.002 mm ◆ Angular tolerance: up to ±0°10′ ◆ Surface roughness: as low as Ra 0.05 μm ◆ Concentricity, cylindricity, flatness, parallelism, straightness: up to 0.02 mm ◆ Minimum hole diameter: 0.5 mm ◆ Internal thread minimum: M2, external thread maximum: M20 Main Machining Equipment ◆ CNC Machining Centers ◆ High-Precision Grinding Machines ◆ Internal and External Cylindrical Grinders ◆ Double-Sided Lapping Machines |

|

Materials We Process

We manufacture using a comprehensive range of technical ceramics:

Aluminum Oxide (Al2O3)

A cost-effective ceramic with excellent hardness, electrical insulation, and wear resistance.

Zirconium Oxide(ZrO2)

High fracture toughness and strength, ideal for structural and wear-resistant applications.

Hot-Pressed Boron Nitride (HPBN)

Machinable ceramic with excellent thermal stability and electrical insulation, used in high-temperature vacuum or inert gas conditions.

Pyrolytic Boron Nitride (PBN)

Ultra-pure and non-wetting to molten metals, ideal for semiconductor crystal growth and high-vacuum applications.

Silicon Nitride (Si3N4)

One of the strongest technical ceramics with superior mechanical properties and excellent thermal shock resistance.

Silicon Carbide (SIC)

Extremely hard and thermally conductive; SSiC and RBSiC are ideal for harsh, high-temperature, and chemically corrosive environments.

Combines high thermal conductivity with excellent electrical insulation, making it perfect for electronic substrates and heat dissipation modules.

Partner with Mascera

Looking for a reliable, full-process partner in ceramic manufacturing?

Contact us to start your custom project.