Hot Pressed Boron Nitride

-

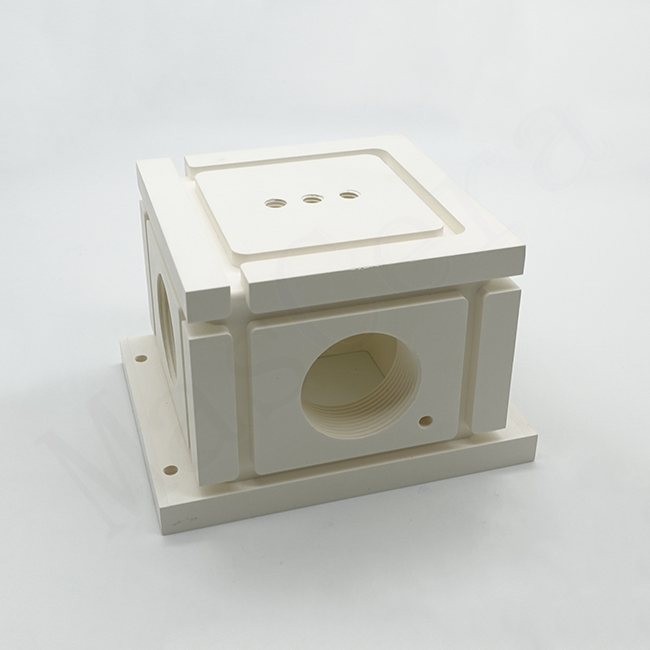

HBN Hot Pressed Boron Nitride Ceramic Parts

Mascera is a specialist in providing Hot Pressed Boron Nitride (HBN) Ceramic, which is known for its excellent electrical insulation, high-temperature resistance under vacuum or gas protection conditions, and exceptional thermal shock resistance. In addition, HBN Ceramic is highly inert to metals and glasses, making it a reliable material for various applications.

Email Details

Mascera can provide boron nitride parts in different compositions and custom designs.

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Boron Nitride Ceramic Rod

Boron nitride rods are produced by high-temperature vacuum hot-press sintering of powdered hexagonal boron nitride. They exhibit excellent resistance to high temperatures, remarkable chemical stability, high electrical insulation properties, and strong resistance to corrosive acids. One unique characteristic of boron nitride rods is their non-wetting properties with most molten metals, making them ideal for producing ceramic nozzles or crucibles for metal smelting applications. In contrast to alumina ceramic or zirconia ceramic, boron nitride rods have a low hardness and excellent machinability, allowing for easy machining using common metalworking tools.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

HBN Boron Nitride Ceramic Tube

Boron nitride tubes made of hot pressed boron nitride ceramics have good electrical insulation, the breakdown voltage is about 3-4 times of alumina ceramic. Therefore, boron nitride tubes could be used as good insulators. By the way, boron nitride tubes also have high temperature resistance and good thermal shock resistance, they can work up to 2100 ℃ under atmosphere protection and 1900 ℃ under vaccum, cracks will not happen even when big temperature changes happen. Boron nitride tubes have low hardness and cannot be used in wear resistance jobs or applications with strong force impact.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Boron Nitride Ceramic Nozzle For Eiga Process

Boron nitride nozzles made of hot pressed boron nitride ceramics have outstanding thermal shock resistance, crack or break will not happen when boron nitride nozzles undergo sudden heating or cooling. The ceramic nozzles have good temperature resistance up to 2100℃ (under inert gas protection). Boron nitride ceramic nozzles are widely applied for metal powder gas atomization because they have no reaction or wetting with molten metals.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

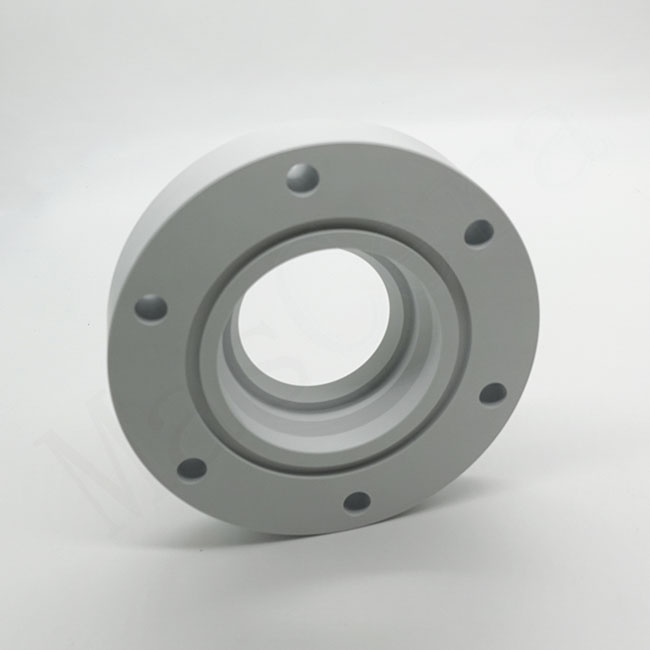

HBN Hot Pressed Boron Nitride Ceramic Rings

Hot Pressed Boron Nitride (BN) Ceramic is an advanced ceramic material which can be used up to 2100℃ under atmosphere proction conditions. Boron nitride ceramic is used as good electrical insulatiors because it has high electrical resistivity and can withstand high breakdown voltage (about 3-4 times of alumina ceramic). Hot pressed boron nitride also has good thermal conductivity and low thermal expansion coefficient, will not crack even using in applications where rapid temperature change will occur. Hot pressed boron nitride ceramic can also be used as metal smelting crucibles because it will not react with most molten metals or glasses. Benefiting from its soft hardness, hot pressed boron nitride ceramic can be machined into high accuracy and complicated components easily with common metal processing tools.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

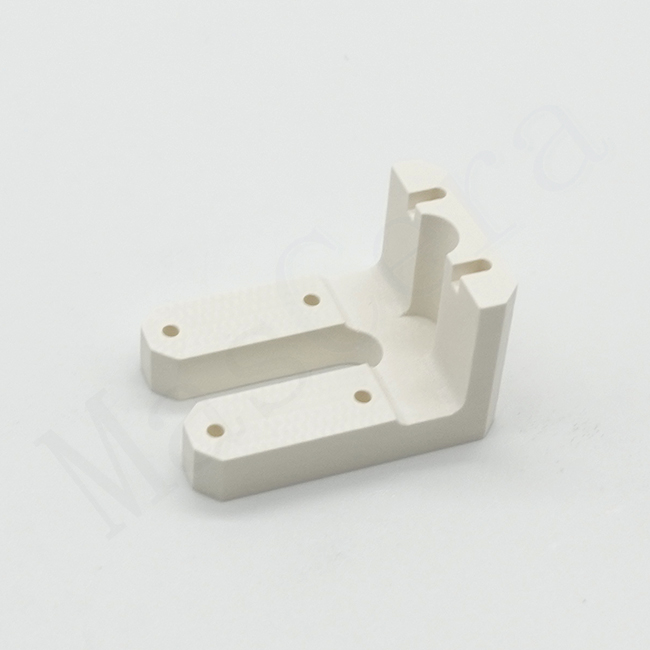

Boron nitride Components for Semiconductor Equipment

The hot-pressed boron nitride produced by Mascera is an advanced ceramic material formed by high-temperature pressing and sintering of hexagonal boron nitride powder. It is highly suitable for the production of various shielding and insulation components used in harsh high-temperature environments.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Hot

Hexagonal Hot Pressed Boron Nitride Crucibles

Mascera is one of leading supplier for boron nitride crucibles, we are capable to produce boron nitride crucibles in cylinderical, conical, square or other customized designs, the delivery time can be 7 days at shortest!

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Hot Pressed Boron Nitride Ceramic Plate

Boron nitride plates are manufactured using hexagonal boron nitride (HBN) powder, which is then processed through high-temperature vacuum hot-pressing sintering. These plates have exceptional resistance to high temperatures, extremely stable chemical properties, high electrical insulation properties, and strong resistance to acidic corrosion. The unique quality of boron nitride plates is their non-wetting characteristic with most molten metals, making them suitable for producing ceramic nozzles or crucibles for metal smelting operations. Compared to alumina ceramic or zirconia ceramic, boron nitride plates have low hardness and excellent machinability, which allows for easy machining using standard metal working tools.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Grade Zsbn Boron Nitride Ceramic Nozzle

ZSBN ceramic is one type of hot pressed boron nitride ceramic, it is a composite material that combines the excellent properties of hot pressed boron nitride and zirconia. ZSBN ceramic not only has the excellent thermal stability and non-wetting property of hot pressed boron nitride, but also has good wear resistance and high strength of zirconia. ZSBN ceramic has perfectly overcome the defect of pure boron nitride ceramic, making it able to be used for applications where good thermal shock resistance, non-wetting property and good wear resistance are needed. ZSBN ceramic is widely applied for molten metal applications such as continuous casting breakrings, metal powder atomizing nozzles, and nozzle for amorphous soft magnetic etc.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139