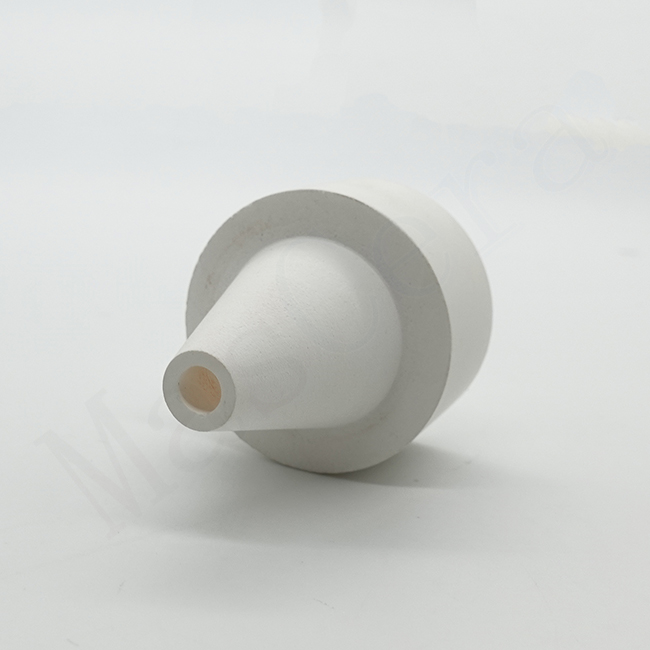

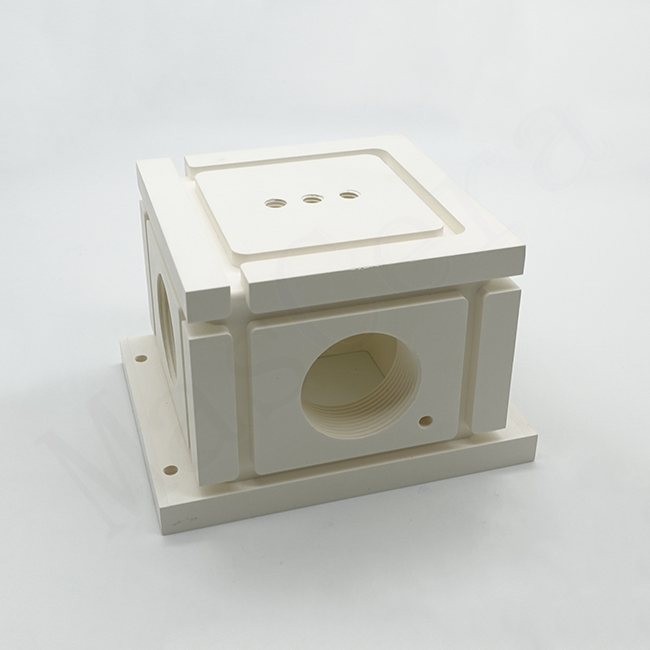

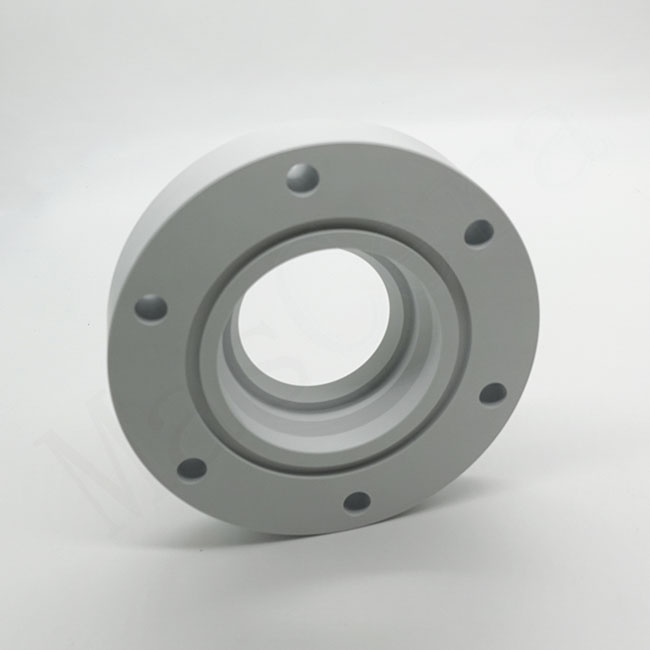

Boron Nitride Ceramic Nozzle For Eiga Process

- MSJ/BN-002

- hot pressed boron nitride

- customized

- 10 pcs per type

- metal powder gas atomization

Boron nitride nozzles made of hot pressed boron nitride ceramics have outstanding thermal shock resistance, crack or break will not happen when boron nitride nozzles undergo sudden heating or cooling. The ceramic nozzles have good temperature resistance up to 2100℃ (under inert gas protection). Boron nitride ceramic nozzles are widely applied for metal powder gas atomization because they have no reaction or wetting with molten metals.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Boron nitride (BN) nozzles made of hot pressed boron nitride ceramics have outstanding thermal shock resistance, crack or break will not happen when boron nitride nozzles undergo sudden heating or cooling. The ceramic nozzles have good temperature resistance up to 2100℃ (under inert gas protection). Boron nitride ceramic nozzles are widely applied for metal powder gas atomization because they have no reaction or wetting with molten metals.

Our company develops a variety of material formula for boron nitride nozzles according to various gas atomization processes and powder materials to meet the needs of different users, we will give suggestion for material selection when inquiry.

Feature of boron nitride nozzles

Good resistance to thermal shocks

Good resistance to high temperature in vacuum&gas protection condition

Will not react with molten metals

Non-wetting with molten metals and the nozzles will not be stuck

Low thermal expansion coefficient

Material Data Sheet

| Item | Unit | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E | BN-S |

|---|---|---|---|---|---|---|---|---|---|

Main Content | - | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN | BN+Si3N4 |

Color | - | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green | Dark Grey |

Density | g/cm3 | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 | 2.2-2.3 |

Flexural Strength | Mpa | 18 | 30 | 65 | 65 | 80 | 90 | 90 | 150 |

Compressive Strength | Mpa | 45 | 85 | 145 | 145 | 175 | 220 | 220 | 380 |

Thermal Conductivity | W/Mk | 35 | 40 | 35 | 35 | 45 | 30 | 85 | 40 |

Thermal Expansion Coefficient (@25 - 1000℃) | 10-6/K | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 |

Max. Service Temp. @Air Condition | ℃ | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. @Vacuum Condition | ℃ | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Max. Service Temp. @Inert Gas Condition | ℃ | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Electrical Resistivity | Ω.Cm | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 | >1013 |

Available shapes of hot pressed boron nitride

Ceramic rod / ceramic pin

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |