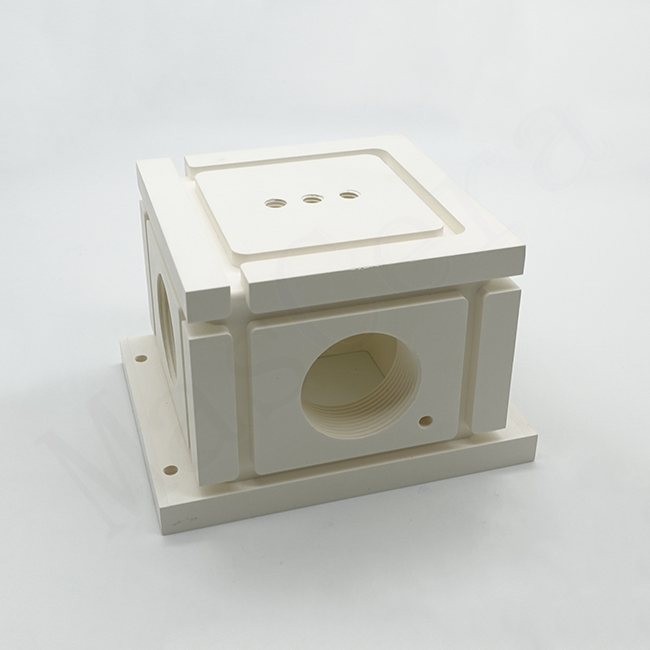

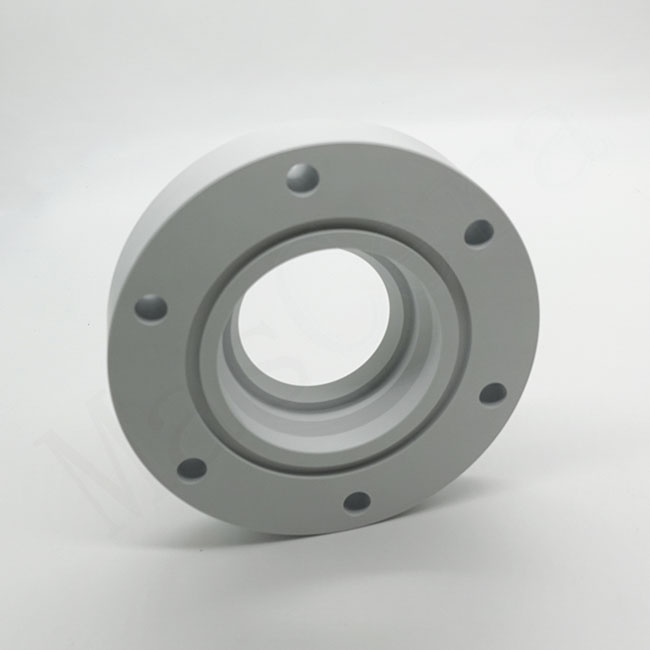

HBN Boron Nitride Ceramic Tube

- MSJ/BN-006

- hot pressed boron nitride (BN99 type)

- customized

- 10 pcs per type

- ceramic insulator parts

Boron nitride tubes made of hot pressed boron nitride ceramics have good electrical insulation, the breakdown voltage is about 3-4 times of alumina ceramic. Therefore, boron nitride tubes could be used as good insulators. By the way, boron nitride tubes also have high temperature resistance and good thermal shock resistance, they can work up to 2100 ℃ under atmosphere protection and 1900 ℃ under vaccum, cracks will not happen even when big temperature changes happen. Boron nitride tubes have low hardness and cannot be used in wear resistance jobs or applications with strong force impact.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Boron nitride tubes made of hot pressed boron nitride ceramics have good electrical insulation, the breakdown voltage is about 3-4 times of alumina ceramic. Therefore, boron nitride tubes could be used as good insulators. By the way, boron nitride tubes also have high temperature resistance and good thermal shock resistance, they can work up to 2100 ℃ under atmosphere protection and 1900 ℃ under vaccum, cracks will not happen even when big temperature changes happen. Boron nitride tubes have low hardness and cannot be used in wear resistance jobs or applications with strong force impact.

Mascera offers tailor-made boron nitride tubes in custom size with high accuracy machining. Except for pure BN99 boron nitride tubes, we also supply boron nitride composites with silicon carbide, calcium borate, aluminum nitride and zirconia, to fulfill various of demand for the customers.

Main properties of boron nitride tubes

Low density

High electrical resistivity

High breakdown voltage resistance

High thermal conductivity

Low thermal expansion coefficient

Good thermal shock resistance

High working temperature in vacuum and gas protection condition

Good corrosion resistance

Non-wetting with metals (without oxidization)

Good Machinability

Typical applications of hot pressed boron nitride

High temperature furnace fixtures and supports

Crucibles or containers for metals or glasses smelting

Break rings for continuous casting of metals

Electrical insulators for high temperature vacuum equipment

Electrical insulator for semiconductor equipment

Thermocouple protection tubes

Material Data Sheet

| Item | Unit | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E | BN-S |

|---|---|---|---|---|---|---|---|---|---|

Main Content | - | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN | BN+Si3N4 |

Color | - | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green | Dark Grey |

Density | g/cm3 | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 | 2.2-2.3 |

Flexural Strength | Mpa | 18 | 30 | 65 | 65 | 80 | 90 | 90 | 150 |

Compressive Strength | Mpa | 45 | 85 | 145 | 145 | 175 | 220 | 220 | 380 |

Thermal Conductivity | W/Mk | 35 | 40 | 35 | 35 | 45 | 30 | 85 | 40 |

Thermal Expansion Coefficient (@25 - 1000℃) | 10-6/K | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 |

Max. Service Temp. @Air Condition | ℃ | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. @Vacuum Condition | ℃ | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Max. Service Temp. @Inert Gas Condition | ℃ | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Electrical Resistivity | Ω.Cm | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 | >1013 |

Performance comparison of boron nitride ceramics and alumina ceramics:

Compared with alumina ceramics, boron nitride ceramics have the following advantages:

1. Boron nitride ceramic has maximum working temperature under atmosphere protection up to 2100 degrees, and alumina ceramic does not exceed 1700 degrees.

2. The thermal shock resistance of boron nitride ceramic is much better than alumina ceramic, boron nitride ceramic will not crack when unergoing rapid temperature rise or fall, it will not crack if it is taken out of the 1000 celsium degree furnace and blowed and quenched continuously for 100 times. Alumina ceramic is easy to crack when working temperature rises or falls quickly.

3. Electrical insulation strength of boron nitride ceramic is 3-4 times that of alumina ceramic.

4. Boron nitride ceramic does not react or bond with moleten glasses or metals, are used as containers for high-temperature sintering or melting crucibles, setter plates, etc.

Compared with alumina ceramics, the disadvantages of boron nitride ceramics are:

1. The strength, hardness and wear resistance of boron nitride ceramics are lower than that of alumina ceramic, and it is not suitable for use under vibration and friction conditions.

2. The use temperature of boron nitride ceramics in the air is only 1000 celsium degrees, and it will oxidize if it exceeds 1000 degrees.

Available shapes of hot pressed boron nitride

Ceramic rod / ceramic pin

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |