News

Everything you need to know about alumina ceramic

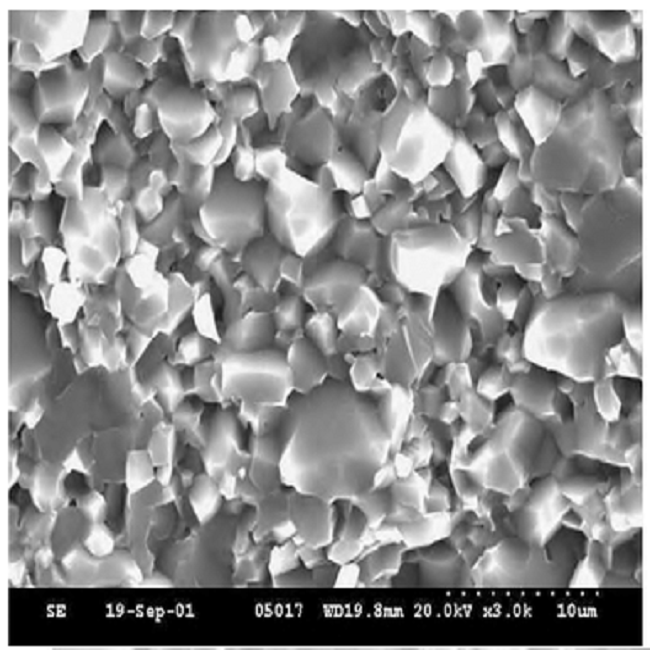

Alumina ceramics is one of the most researched and widely used materials among technical ceramics.

13-07-2022-

Everything you need to know about alumina ceramic

Alumina ceramics is one of the most researched and widely used materials among technical ceramics.

13-07-2022 -

How to Choose the Right Alumina Ceramic for Your Application

Learn how to select the right alumina ceramic grade based on application, geometry, and manufacturing process. A practical guide with part-specific recommendations.

14-01-2026 -

Alumina Ceramic Grades Guide: Choosing Between 95% to 99.8% Purity

Explore the differences between alumina ceramic grades (95%–99.8%). Learn how aluminum oxide purity affects electrical insulation, thermal behavior, and industrial applications.

14-01-2026 -

Thermal Conductivity of Alumina Ceramic

Thermal conductivity is one of the most important physical characteristics of alumina ceramic and a key factor in its widespread use across electronic, electrical, and high-temperature industrial applications.

07-01-2026 -

Electrical Insulation Properties of Alumina Ceramic

Electrical insulation is a critical property of alumina ceramic, making it an essential material in electronic, electrical, and high-voltage applications. In many designs, alumina ceramics are selected not primarily for their mechanical strength, but for their ability to provide stable alumina ceramic electrical insulation under demanding operating conditions.

05-01-2026 -

Silicon Carbide for Laser Processing Applications: Enhancing Laser Damage Resistance and Thermal Stability

Among advanced ceramics, Silicon Carbide (SiC) is emerging as a leading material. Its combination of high laser damage resistance, high thermal conductivity, and overall stability makes it exceptionally suitable for modern laser processing applications.

03-12-2025

-

Expansion of Multi-Wire Sawing Technology and Production Capabilities for Precision Ceramics in Europe

At the start of 2025, KYOCERA Fineceramics Europe GmbH announced the establishment of a new facility in Erfurt, Germany, enhancing its existing multi-wire saw technology capabilities and production infrastructure.

21-01-2025 -

Indian Tech Firm to Invest 2.9 Billion RMB in Silicon Carbide Semiconductor Plant

On December 23, media outlets such as The Economic Times reported that Silectric Semiconductor, a subsidiary of Zoho Corporation, will establish Karnataka's first semiconductor manufacturing plant in India, dedicated to integrated production of silicon carbide.

31-12-2024 -

Development of Silicon Nitride for Advanced Chip Testing Applications

Recently, Kyocera announced the development of a new silicon nitride ceramic material for functional testing of next-generation microchips. This new material boasts enhanced thermal expansion properties and flexural strength, enabling the production of thin silicon nitride plates with extremely narrow spacing between contact probes, which is critical for testing next-generation microchips.

05-11-2024 -

60 Million Investment in the Construction of a Medical Implant Precision Ceramics Facility

Recently, KYOCERA held a groundbreaking ceremony for its fine ceramics factory for medical implants, located in Waiblingen, near Stuttgart, Germany. This facility will specialize in manufacturing high-quality ceramic heads used in hip prostheses and other implant applications. The project is expected to be completed by September next year.

14-10-2024 -

Construction Begins on Second Phase of World’s Largest High-Purity Alumina Plant

Recently, Alpha HPA, an Australian company, has commenced construction on the second phase of the world’s largest single-location ultra-high-purity alumina refinery.

13-09-2024 -

Silicon Carbide Ceramics Market for Semiconductors to Reach $1.578 Billion by 2030

According to data from QY Research, the global market size for silicon carbide (SiC) ceramics used in semiconductors was $1.111 billion in 2023. Driven by the rigid demand from downstream industries, it is projected that the silicon carbide ceramics market will grow to $1.578 billion by 2030, with a compound annual growth rate (CAGR) of 5.09% from 2024 to 2030.

09-08-2024

-

Notice for 2026 Spring Festival Holiday

Mascera will be closed for the 2026 Chinese New Year holiday from February 14th, 2026 to February 22nd, 2026.

07-02-2026 -

Notice for 2025 National Day holiday

25-09-2025 -

Notice for 2025 Labor Day holiday

21-04-2025 -

Notice for 2025 Spring Festival Holiday

15-01-2025 -

Notice for 2024 National Day holiday

30-09-2024