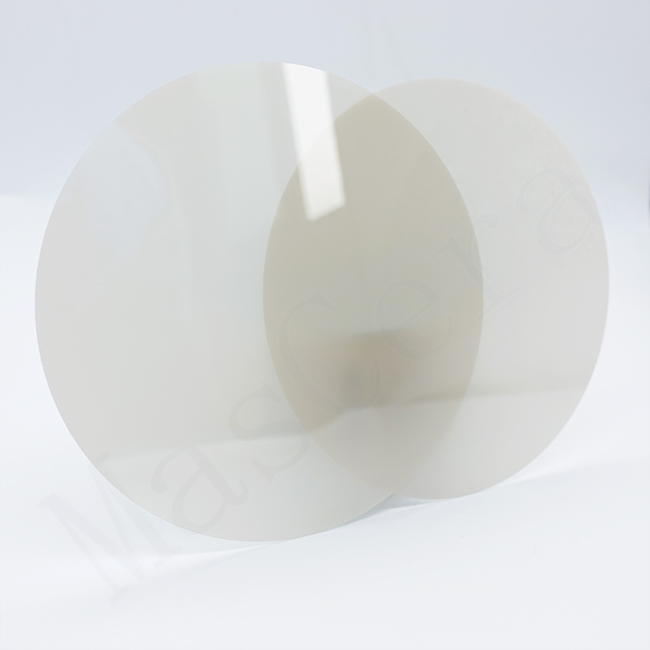

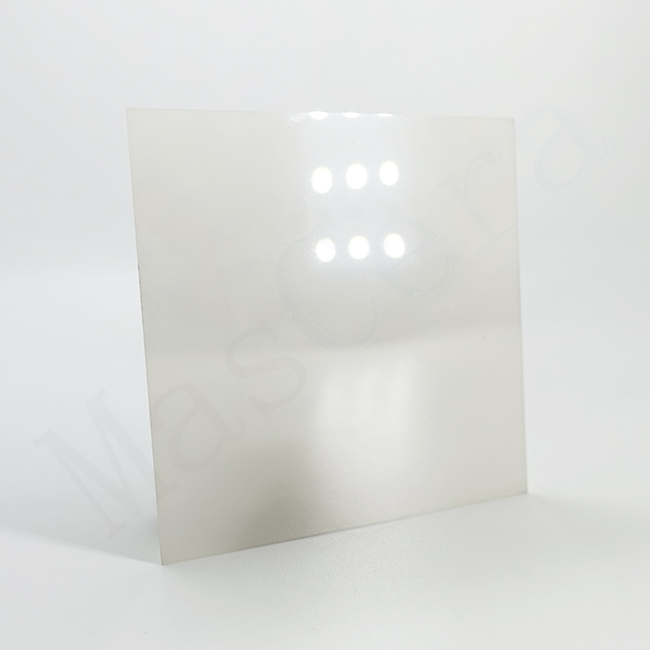

Mirror Polished Aln Aluminum Nitride Ceramic Plate

- MSJ/ALN-001

- aluminum nitride ceramic

- customized

- 10 pcs per type

- industrial applications

Aluminium Nitride (AlN) is a highly desirable material for applications that demand high thermal conductivity and electrical insulation properties. This makes it an ideal choice for thermal management and electrical applications.Furthermore, Aluminium Nitride ceramics exhibits a coefficient of thermal expansion and electrical insulation properties that closely resemble those of Silicon wafer material. As a result, it proves to be a valuable material for electronics applications where high temperatures and efficient heat dissipation are often challenging factors

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Aluminium Nitride (AlN) is a highly desirable material for applications that demand high thermal conductivity and electrical insulation properties. This makes it an ideal choice for thermal management and electrical applications. In the semiconductor industry, AlN is frequently used as a substitute for Beryllium Oxide (BeO) due to its non-toxic nature when machined. Furthermore, Aluminium Nitride ceramics exhibits a coefficient of thermal expansion and electrical insulation properties that closely resemble those of Silicon wafer material. As a result, it proves to be a valuable material for electronics applications where high temperatures and efficient heat dissipation are often challenging factors.

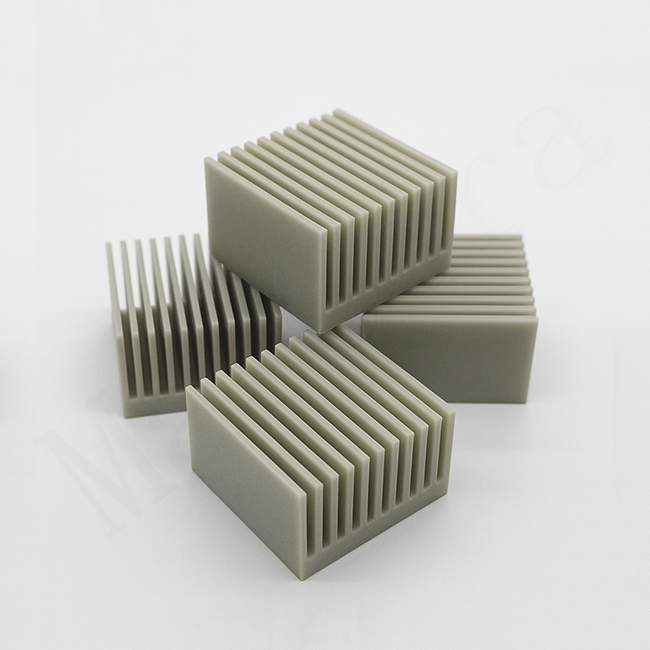

Mascera is able to provide aluminum nitride ceramics in custom size and design, we can provide ceramic plates, ceramic rods, ceramic tubes, ceramic rings and other irregular shapes. We have capability to machine the parts to very precise tolerances with a fine grinding or polishing surface.

Main properties of aluminum nitride ceramic

High mechanical strength

Good electrical insulation

Low dielectric constant and dielectric loss

Similar thermal expansion with Silicon

High thermal conductivity

Excellent corrosion resistance

Non-toxic

Typical applications of aluminum nitride ceramic

1. Optical communication device application

2. Special refrigerator

3. LED industry

4. Automotive electronic modules

5. High efficiency power module

6. High frequency microwave application

7. Power electronic components

Material Data Sheet

| ITEM | UNIT | TECHNICAL PARAMETERS |

|---|---|---|

| Purity | % | 95 |

| Color | ‐ | Light Grey |

| Density | g/cm3 | ≥3.30 |

| Hardness (HV0.5) | - | 1130 |

| Young’s modulus | Gpa | 310-320 |

| Fracture Toughness | Mpa.m1/2 | 3.5 |

| Flexural Strength @25℃ | Mpa | 330 |

| Compressive Strength @25℃ | Mpa | 2100 |

| Thermal conductivity @25℃ | W/M.K | ≥170 |

Coefficient of Thermal Expansion(20~300℃) | 10-6/℃ | 4.7 |

| Thermal shock resistance | △℃ | 400 |

Max. Working Temperature @Air conditio | ℃ | 900 |

Max. Working Temperature @Inert gas protection condition | ℃ | 1800 |

| Melting Point | ℃ | 2500 |

| Dielectric Strength | KV/mm | 17 |

| Volume Resistivity | Ω.cm | >1014 |

Dielectric Constant(1MHz, 25℃) | - | 9 |

| Dielectric Loss (1MHz, 25℃) | - | 0.001 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |