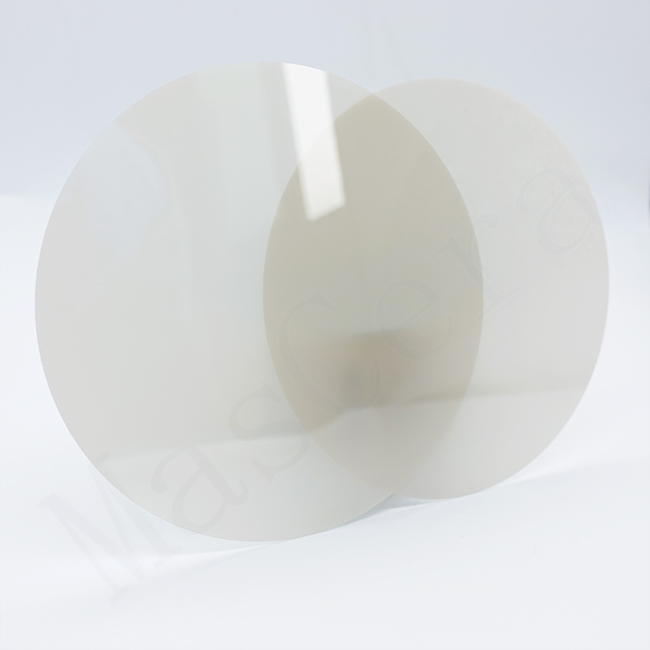

Aluminum Nitride (AlN) Sealing Ring

- MSJ/ALN-008

- aluminum nitride / aln ceramic

- customized

- 10 pcs per type

- electronic components

The Aluminum Nitride (AlN) Sealing Ring is a precision-machined technical ceramic component designed for applications requiring both excellent electrical insulation and efficient heat transfer.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

The Aluminum Nitride (AlN) Sealing Ring is a precision-machined technical ceramic component designed for applications requiring both excellent electrical insulation and efficient heat transfer. With high thermal conductivity, stable mechanical strength, and a thermal expansion coefficient close to metals, AlN sealing rings are widely used in structural sealing, insulation interfaces, and thermal management areas.

Mascera manufactures customed AlN rings according to customer drawings, including inner/outer diameter, thickness, tolerances, and surface finish requirements.

Main properties

High thermal conductivity (up to 170 W/m·K) for rapid heat dissipation

Excellent electrical insulation with high dielectric strength

Low thermal expansion closely matched to aluminum and stainless steel

Good mechanical strength and dimensional stability

High purity suitable for demanding environments

Resistance to thermal shock, corrosion, and high temperature

Fully customed sizes available per drawing

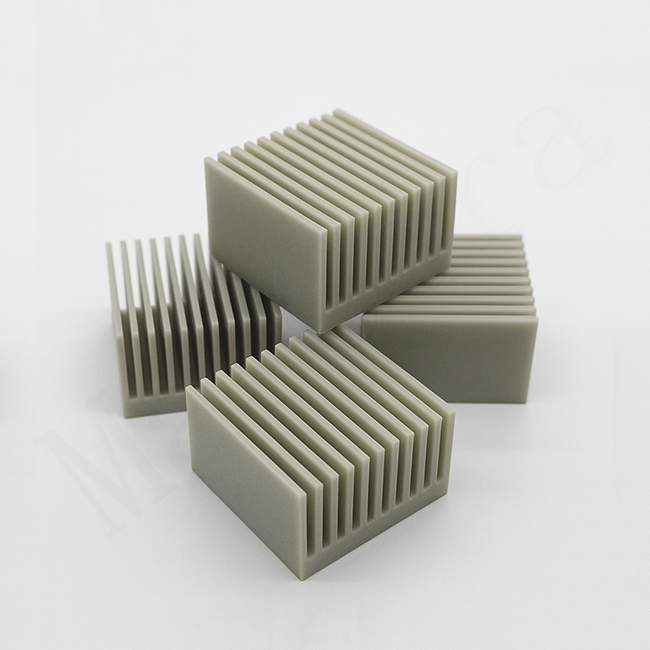

Typical applications

Although widely used in various industrial fields, AlN ceramic sealing rings are especially suitable for:

Structural sealing components

Electrical insulation rings

Precision mechanical interfaces

High-temperature sealing structures

Battery sealing assemblies

Thermal management and structural isolation

Custom Options

Mascera provides completely customed AlN ceramic rings with options including:

Inner diameter / outer diameter / thickness

Tolerance and flatness

Surface finish

Chamfers, bevels, slots, or positioning features

Send your drawing or specification, and we will provide engineering support and quotation.

Material Data Sheet

| ITEM | UNIT | TECHNICAL PARAMETERS |

|---|---|---|

| Purity | % | 95 |

| Color | ‐ | Light Grey |

| Density | g/cm3 | ≥3.30 |

| Hardness (HV0.5) | - | 1130 |

| Young’s modulus | Gpa | 310-320 |

| Fracture Toughness | Mpa.m1/2 | 3.5 |

| Flexural Strength @25℃ | Mpa | 330 |

| Compressive Strength @25℃ | Mpa | 2100 |

| Thermal conductivity @25℃ | W/M.K | ≥170 |

Coefficient of Thermal Expansion(20~300℃) | 10-6/℃ | 4.7 |

| Thermal shock resistance | △℃ | 400 |

Max. Working Temperature @Air conditio | ℃ | 900 |

Max. Working Temperature @Inert gas protection condition | ℃ | 1800 |

| Melting Point | ℃ | 2500 |

| Dielectric Strength | KV/mm | 17 |

| Volume Resistivity | Ω.cm | >1014 |

Dielectric Constant(1MHz, 25℃) | - | 9 |

| Dielectric Loss (1MHz, 25℃) | - | 0.001 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Why Choose Us

10+ years experience in technical ceramics manufacturing and R&D

ISO9001:2015 certificated quality control management system

Different types of ceramic materials are provided for your different applications

Products have been exported to 40+ countries and have good reputation from our customers

MOQ is low, both prototype and bulk order will keep high quality

Any of your inquiries or questions will be responded no longer than 24 hours

Rigorous production plan to ensure on-time delivery