Boron nitride Components for Semiconductor Equipment

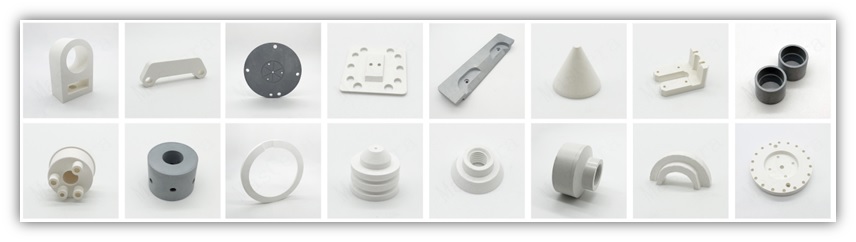

- MSJ/BN-013

- boron nitride ceramic

- customized

- 5 pcs per type

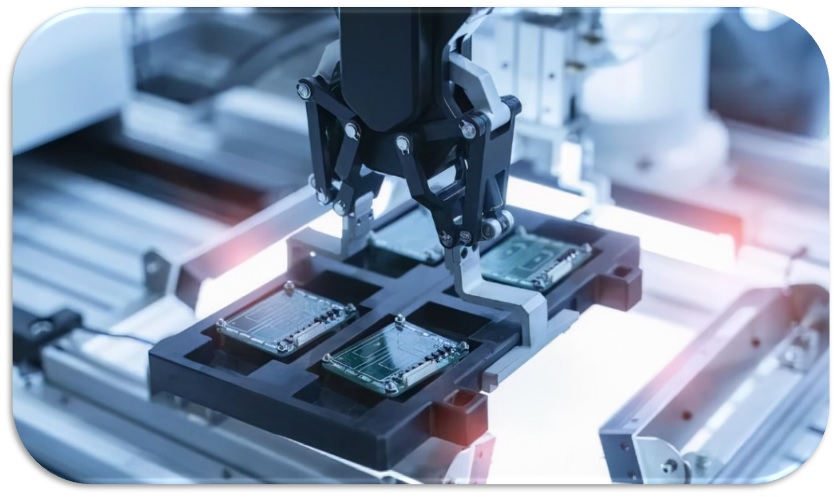

- Semiconductor Equipment

The hot-pressed boron nitride produced by Mascera is an advanced ceramic material formed by high-temperature pressing and sintering of hexagonal boron nitride powder. It is highly suitable for the production of various shielding and insulation components used in harsh high-temperature environments.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

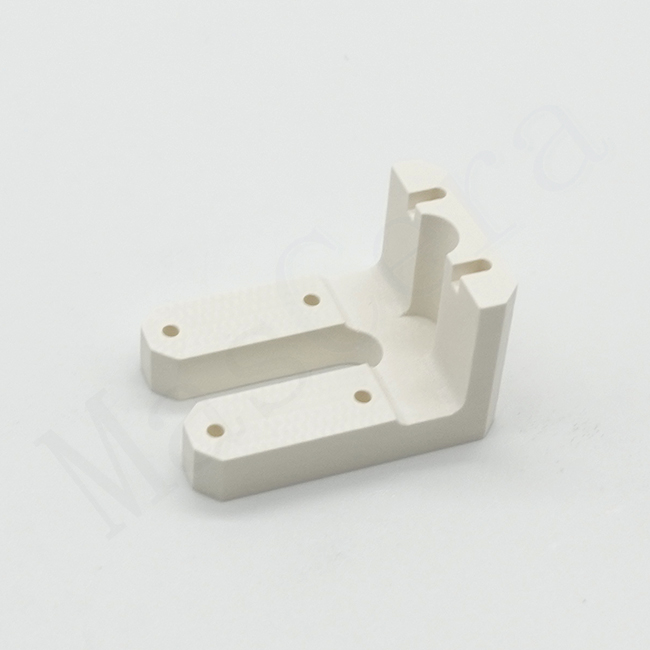

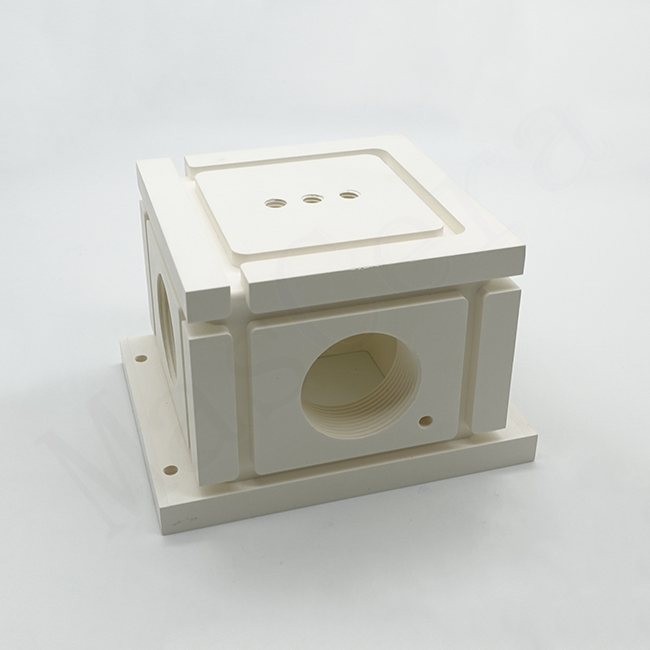

Product detail

The hot-pressed boron nitride produced by Mascera is an advanced ceramic material formed by high-temperature pressing and sintering of hexagonal boron nitride powder. It is a dense and easily machinable material that exhibits properties such as high temperature resistance, low thermal expansion coefficient, low friction coefficient, excellent dielectric strength and insulation. These characteristics make it highly suitable for various shielding and insulation components in harsh high-temperature environments. These components, including insulation shrouds and rails, target frames, protective tubes, shields, and liners, ensure that the PVD arc remains confined to the target area, preventing equipment damage.

Main properties

|

|  |

Material Data Sheet

| Item | Unit | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E | BN-S |

|---|---|---|---|---|---|---|---|---|---|

Main Content | - | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN | BN+Si3N4 |

Color | - | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green | Dark Grey |

Density | g/cm3 | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 | 2.2-2.3 |

Flexural Strength | Mpa | 18 | 30 | 65 | 65 | 80 | 90 | 90 | 150 |

Compressive Strength | Mpa | 45 | 85 | 145 | 145 | 175 | 220 | 220 | 380 |

Thermal Conductivity | W/Mk | 35 | 40 | 35 | 35 | 45 | 30 | 85 | 40 |

Thermal Expansion Coefficient (@25 - 1000℃) | 10-6/K | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 |

Max. Service Temp. @Air Condition | ℃ | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. @Vacuum Condition | ℃ | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Max. Service Temp. @Inert Gas Condition | ℃ | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Electrical Resistivity | Ω.Cm | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 | >1013 |

Tips for Using

1.Working temperature in the air should not exceed 900℃, oxidation will occur when more than 900°C.

2.The components shall be stored in the dry environment inside a sealed container.

3.Never wash the component with water. Use fine sandpaper or cloth to remove any dirts or residues.

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |