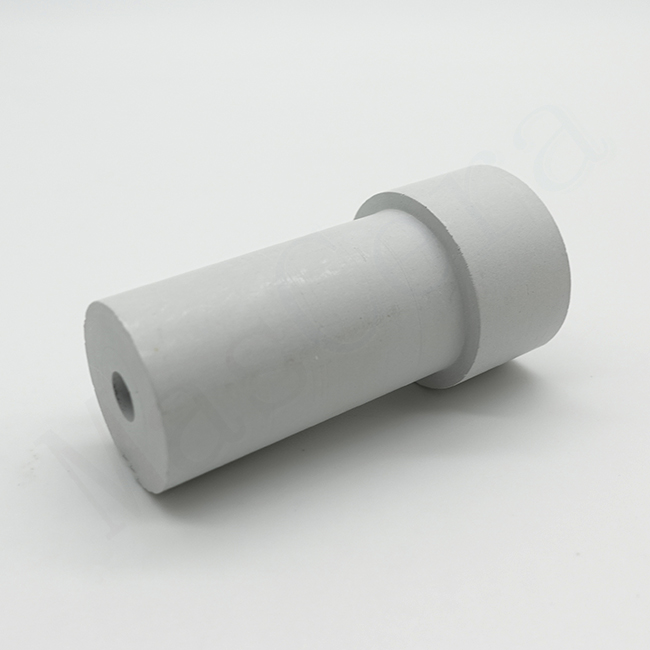

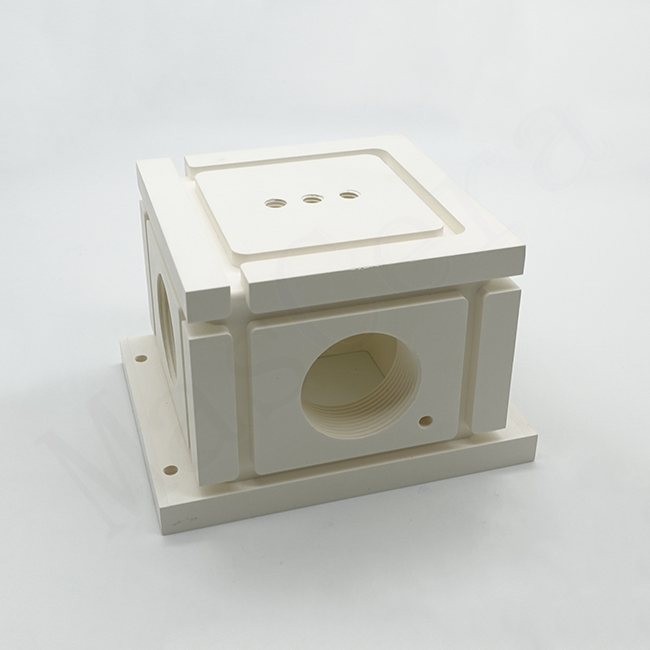

Grade Zsbn Boron Nitride Ceramic Nozzle

- MSJ/BN-008

- ZSBN ceramic (BN-B)

- customized

- 10 pcs per type

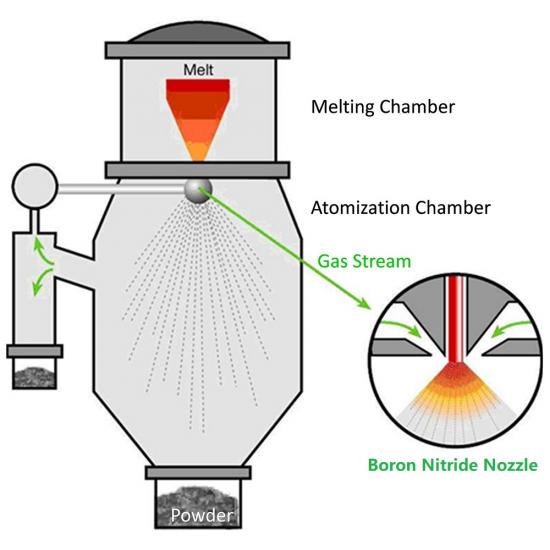

- metal powder gas atomization

ZSBN ceramic is one type of hot pressed boron nitride ceramic, it is a composite material that combines the excellent properties of hot pressed boron nitride and zirconia. ZSBN ceramic not only has the excellent thermal stability and non-wetting property of hot pressed boron nitride, but also has good wear resistance and high strength of zirconia. ZSBN ceramic has perfectly overcome the defect of pure boron nitride ceramic, making it able to be used for applications where good thermal shock resistance, non-wetting property and good wear resistance are needed. ZSBN ceramic is widely applied for molten metal applications such as continuous casting breakrings, metal powder atomizing nozzles, and nozzle for amorphous soft magnetic etc.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

ZSBN ceramic is one type of hot pressed boron nitride ceramic, it is a composite material that combines the excellent properties of hot pressed boron nitride and zirconia. ZSBN ceramic not only has the excellent thermal stability and non-wetting property of hot pressed boron nitride, but also has good wear resistance and high strength of zirconia. ZSBN ceramic has perfectly overcome the defect of pure boron nitride ceramic, making it able to be used for applications where good thermal shock resistance, non-wetting property and good wear resistance are needed. ZSBN ceramic is widely applied for molten metal applications such as continuous casting breakrings, metal powder atomizing nozzles, and nozzle for amorphous soft magnetic etc.

excellent thermal stability and non-wetting property of hot pressed boron nitride, but also has good wear resistance and high strength of zirconia. ZSBN ceramic has perfectly overcome the defect of pure boron nitride ceramic, making it able to be used for applications where good thermal shock resistance, non-wetting property and good wear resistance are needed. ZSBN ceramic is widely applied for molten metal applications such as continuous casting breakrings, metal powder atomizing nozzles, and nozzle for amorphous soft magnetic etc.

Mascera is a reputable supplier for high quality hot pressed boron nitride ceramics, we have developped several grades of materail for different property requirement. Except for high purity 99% boron nitride ceramic, we also supply boron nitride ceramic composited with zirconia ceramic, aluminum nitride, silicon carbide and alumina ceramic etc. Welcome to contact us when you have demand, we will do our best to match your demands.

Main properties of ZSBN ceramic

Good resistance to molten metals wetting

High temperature resistance

Excellent thermal shock resistance against temperature changes

Enhanced wear resistance and mechanical strength than pure boron nitride

High thermal conductivity

Good corrosion resistance

Typical applications of ZSBN ceramic

Side sealing plate for thin strip casting

Guide tube for high temperature metal solutions

Nozzles for metal powder gas atomization

Nozzles for spraying of amorphous strip

Break rings for horizontal continuous casting

Material Data Sheet

| Item | Unit | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E | BN-S |

|---|---|---|---|---|---|---|---|---|---|

Main Content | - | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN | BN+Si3N4 |

Color | - | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green | Dark Grey |

Density | g/cm3 | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 | 2.2-2.3 |

Flexural Strength | Mpa | 18 | 30 | 65 | 65 | 80 | 90 | 90 | 150 |

Compressive Strength | Mpa | 45 | 85 | 145 | 145 | 175 | 220 | 220 | 380 |

Thermal Conductivity | W/Mk | 35 | 40 | 35 | 35 | 45 | 30 | 85 | 40 |

Thermal Expansion Coefficient (@25 - 1000℃) | 10-6/K | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 |

Max. Service Temp. @Air Condition | ℃ | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. @Vacuum Condition | ℃ | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Max. Service Temp. @Inert Gas Condition | ℃ | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Electrical Resistivity | Ω.Cm | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 | >1013 |

Available shapes of hot pressed boron nitride

Ceramic rod / ceramic pin

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |