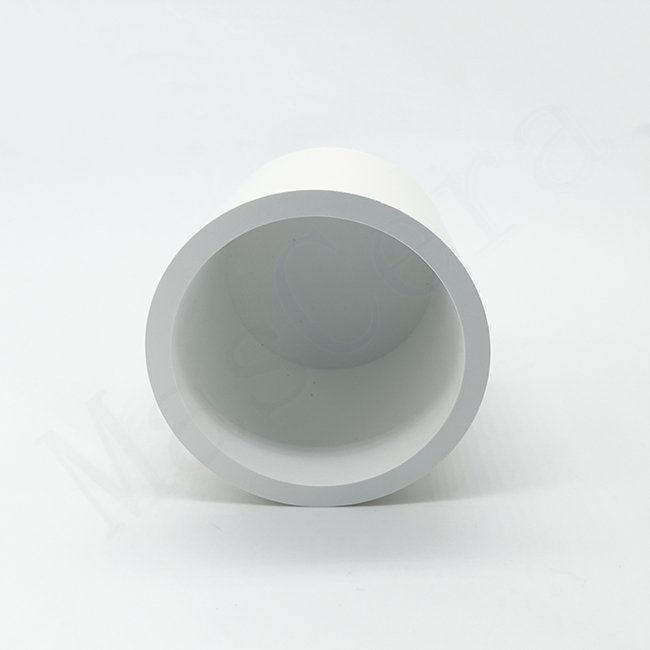

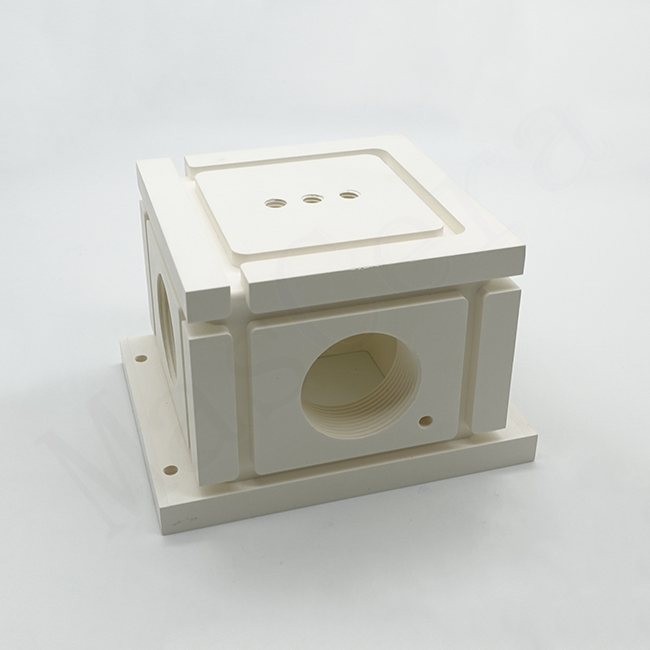

Hexagonal Hot Pressed Boron Nitride Crucibles

- MSJ/BN-003

- BN99 boron nitride ceramic

- customized

- 10 pcs per type

- metal smelting

Mascera is one of leading supplier for boron nitride crucibles, we are capable to produce boron nitride crucibles in cylinderical, conical, square or other customized designs, the delivery time can be 7 days at shortest!

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Hot-pressed boron nitride (HBN) ceramic is an ideal material for metal smelting crucibles due to its exceptional thermal stability, chemical inertness, and non-wetting properties. It does not react with most molten metals, preventing contamination and ensuring a clean smelting process.

Mascera’s boron nitride crucibles are primarily manufactured from high-purity BN99 boron nitride ceramic, which has minimal impurities and offers superior performance in high-temperature environments. Our BN crucibles provide excellent thermal shock resistance and outstanding durability, with a maximum working temperature of 2100°C in inert gas protection and 1900°C in vacuum conditions.

Key Properties of Boron Nitride Crucibles

● Low thermal expansion coefficient, reducing thermal stress

● Excellent thermal shock resistance, ensuring durability under rapid temperature changes

● High working temperature capability, performing reliably in vacuum and gas protection environments

● Superior corrosion resistance, preventing degradation in harsh conditions

● Non-wetting with molten metals, eliminating contamination risks

● Easy machinability, allowing custom fabrication for specific applications

Applications of Boron Nitride Crucibles

Our high-purity boron nitride crucibles are widely used for sintering and smelting of various materials, including:

● Nonferrous and ferrous metals, such as Al, Bi, Ge, Sb, Sn, Cd, Pb, Ni, Zn, Cu, Mg, In, Fe.

● Stainless Steel

● Glass melting, including soda glass, cryolite-based glass melts

● Molten silicon, fluoride compounds, and slag processing

Material Data Sheet

| Item | Unit | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E | BN-S |

|---|---|---|---|---|---|---|---|---|---|

Main Content | - | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN | BN+Si3N4 |

Color | - | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green | Dark Grey |

Density | g/cm3 | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 | 2.2-2.3 |

Flexural Strength | Mpa | 18 | 30 | 65 | 65 | 80 | 90 | 90 | 150 |

Compressive Strength | Mpa | 45 | 85 | 145 | 145 | 175 | 220 | 220 | 380 |

Thermal Conductivity | W/Mk | 35 | 40 | 35 | 35 | 45 | 30 | 85 | 40 |

Thermal Expansion Coefficient (@25 - 1000℃) | 10-6/K | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 |

Max. Service Temp. @Air Condition | ℃ | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. @Vacuum Condition | ℃ | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Max. Service Temp. @Inert Gas Condition | ℃ | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Electrical Resistivity | Ω.Cm | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 | >1013 |

Usage Tips for Boron Nitride Crucibles

To extend the lifespan and maintain the high performance of BN crucibles, follow these best practices:

● Always operate the boron nitride crucible under a protective gas environment (Ar or N₂) for optimal longevity.

● Avoid exceeding 900°C in air, as oxidation occurs beyond this temperature.

● Store the BN crucible in a dry, sealed container to prevent moisture absorption.

● Never clean the boron nitride ceramic crucible with water; use fine sandpaper or a dry cloth to remove dirt or residues.

● Avoid using boron nitride crucibles with Sb₂O₃, chromium oxide, molybdenum trioxide, arsenic trioxide, titanium carbide, high-lead glass glaze, boron phosphate, potassium phosphate, or chlorine compounds.

Why Choose Mascera’s Boron Nitride Crucibles?

● High-purity BN99 material, ensuring superior performance

● Precision-machined BN crucibles, available in custom sizes and shapes

● Reliable thermal and chemical stability, ideal for demanding industrial applications

● Direct manufacturer supply, ensuring competitive pricing and consistent quality

For more information on our boron nitride crucibles, BN ceramic crucibles, or to request a custom hot-pressed boron nitride crucible, contact Mascera today!

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |