Silicon Carbide for Laser Processing Applications: Enhancing Laser Damage Resistance and Thermal Stability

As high-power fiber-laser systems grow in metal fabrication, precision machining, and electronics manufacturing, the demand for materials capable of withstanding extreme optical energy is rapidly increasing. Among advanced ceramics, Silicon Carbide (SiC) is emerging as a leading material. Its combination of high laser damage resistance, high thermal conductivity, and overall stability makes it exceptionally suitable for modern laser processing applications.

Why Silicon Carbide (SiC) Excels in Laser Processing Applications?

1. Outstanding Laser Damage Resistance

Silicon Carbide (SiC) is highly valued for its exceptional laser damage resistance, especially in high-energy environments. With a melting point near 2700 °C, SiC maintains structural integrity under intense laser exposure. Other advanced ceramics—such as alumina, zirconia, and aluminum nitride—may darken, crack, or burn.

SiC's strong covalent bonding structure and low optical absorption enable far superior laser damage resistance.

2. High Thermal Conductivity and Low Absorption at Laser Wavelength

Efficient heat dissipation is crucial for all laser processing applications.

Silicon Carbide (SiC) provides:

♦ High thermal conductivity of 120–200 W/m·K

♦ Low absorption at the common 1064 nm fiber-laser wavelength

♦ Reduced risk of thermal cracking or surface burning

This balance of high thermal conductivity and optical stability differentiates SiC from other advanced ceramics, making it ideal for demanding thermal-laser cycles.

3. Mechanical and Thermal Stability Under High-Energy Laser Conditions

In dynamic laser processing applications, components experience rapid heating, particle impact, and mechanical vibration.

Silicon Carbide (SiC) maintains stability due to:

♦ Hardness close to Mohs 9

♦ Strong thermal-shock resistance

♦ High stiffness and dimensional stability

These properties help SiC retain flatness and alignment accuracy—critical for substrates, masks, optical fixtures, and structural elements.

4. Chemical Inertness Against Metal Vapor

During high-energy laser cutting or welding, hot metal vapor and oxide particles can chemically react with many materials.

Silicon Carbide (SiC) remains chemically inert and resists corrosion, maintaining stable performance and consistent laser damage resistance throughout long-term industrial use.

Comparison of Silicon Carbide with Other Advanced Ceramics

| Property | Silicon Carbide (SiC) | Alumina | Aluminum Nitride | Zirconia | Silicon Nitride |

|---|---|---|---|---|---|

| Laser Damage Resistance | Excellent | Weak | Weak | Poor | Moderate |

| Thermal Conductivity (W/m·K) | 120–200 | 18–30 | 170–200 | 2–3 | 15–30 |

| Melting / Decomposition Temperature | ≈2700°C | ≈2050°C | ≈2200°C | ≈2700°C (unstable) | ≈1900°C |

| Thermal Shock Resistance | High | Medium | Poor | Poor | Medium |

| Hardness | High | Medium | Medium | High | Medium |

| Chemical Inertness | High | Medium | Low | Medium | Medium |

This comparison demonstrates why Silicon Carbide (SiC) provides one of the best overall performance profiles among advanced ceramics for laser processing applications.

Mascera's Perspective: Supporting SiC Adoption in Laser Technologies

Mascera specializes in advanced ceramics, including Silicon Carbide (SiC), alumina, and silicon nitride. Although laser-specific components are not yet the core of our product portfolio, demand for SiC parts with laser damage resistance and high thermal conductivity is increasing steadily.

We currently support customers through:

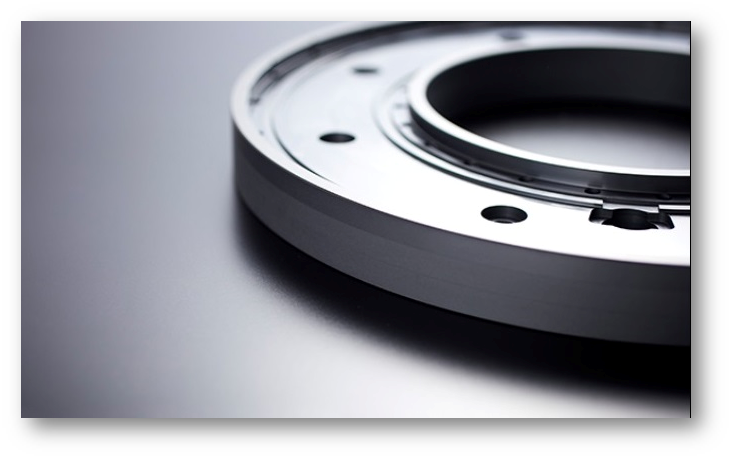

♦ SiC substrate development

♦ Laser-resistant ceramic fixtures

♦ High-precision structural ceramic components

♦ Small-batch and prototype production for laser processing applications

With expertise in material behavior and machining of advanced ceramics, Mascera aims to expand SiC capabilities to meet the evolving needs of next-generation laser systems.