Alumina Ceramic Grades Guide: Choosing Between 95% to 99.8% Purity

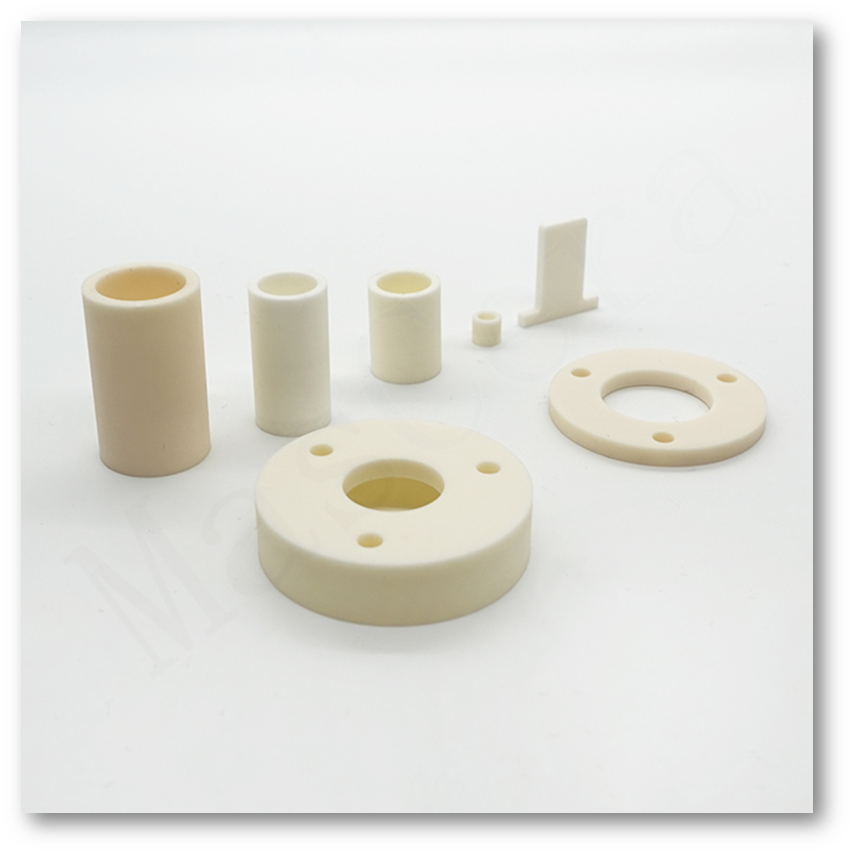

Alumina ceramic is one of the most widely used technical ceramic materials in industrial and electronic applications. It is commonly classified by its aluminum oxide (Al₂O₃) content, expressed as a percentage such as 80%, 96%, or 99.6%. While higher purity is often associated with improved material performance, alumina ceramic purity alone does not determine whether a material is suitable for a specific application.

material performance, alumina ceramic purity alone does not determine whether a material is suitable for a specific application.

In technical ceramic and electronic applications, however, alumina grades in the 95%–99.8% purity range are most commonly specified, as they offer a practical balance between electrical insulation performance, thermal behavior, mechanical stability, and manufacturability. This article therefore focuses on these commonly used technical alumina ceramic grades.

Note: This technical analysis is part of our “Everything You Need to Know About Alumina Ceramic” series. To see how these grades affect specific performance, explore our guides on Electrical Insulation and Thermal Conductivity.

How Alumina Purity Is Defined

Alumina ceramic purity refers to the percentage of aluminum oxide (Al₂O₃) present in the ceramic body. The remaining fraction consists of trace oxides and sintering additives that are intentionally introduced to control densification behavior, grain growth, and manufacturing stability.

For example, a 96% alumina ceramic contains approximately 96% Al₂O₃, with the balance made up of carefully controlled secondary phases. These additions do not imply inferior quality; rather, they are often essential for achieving consistent microstructure, reliable sintering, and cost-effective production.

As a result, alumina purity should be understood as a material classification parameter, not as a direct or absolute ranking of performance.

Overview of Common Alumina Ceramic Grades

In industrial practice, alumina ceramics are commonly grouped into several purity ranges. Each grade offers a different combination of properties and is optimized for specific application requirements rather than absolute performance.

The most frequently referenced grades include:

▪ 95% alumina

▪ 96% alumina

▪ 99% alumina

▪ High-purity alumina grades (99.5%, 99.7%, and 99.8%)

The following sections explain how each grade is typically used and understood in engineering contexts.

95% Alumina Ceramic

95% alumina ceramic is widely used in general industrial applications where reliable performance and cost efficiency are required.

Key characteristics

▪ Good mechanical strength and wear resistance

▪ Stable electrical insulation

▪ Cost-effective and well-established manufacturing processes

Typical applications

▪ General electrical insulators

▪ Industrial structural components

▪ Wear-resistant parts under moderate operating conditions

95% alumina is often selected for large-volume applications due to its mature processing routes and consistent performance. It provides a practical balance between material properties and production cost.

96% Alumina Ceramic

96% alumina ceramic is one of the most commonly used grades in electronic and electrical applications and represents a key engineering material in many systems.

Key characteristics

▪ Balanced electrical insulation, thermal behavior, and mechanical stability

▪ Improved consistency compared to lower-purity grades

▪ Excellent compatibility with metallization processes

Typical applications

▪ Electrical insulating washers and spacers

▪ Metallized ceramic substrates

▪ Electronic and power-related insulating components

96% alumina is widely regarded as a mainstream electronic ceramic material, offering predictable performance and good process compatibility. It is frequently used where electrical insulation and thermal stability must be achieved simultaneously.

99% Alumina Ceramic

99% alumina ceramic is typically selected when higher material consistency and improved performance stability are required.

Key characteristics

▪ Enhanced electrical insulation reliability

▪ Improved thermal conductivity compared to standard grades

▪ Higher chemical stability

Typical applications

▪ High-voltage components

▪ Power electronics operating under increased electrical stress

▪ Precision ceramic components requiring improved material uniformity

While 99% alumina offers improved performance in certain areas, it also involves higher processing requirements. Selection is usually driven by application-specific needs rather than purity alone.

High-Purity Alumina Ceramics (99.5%, 99.7%, 99.8%)

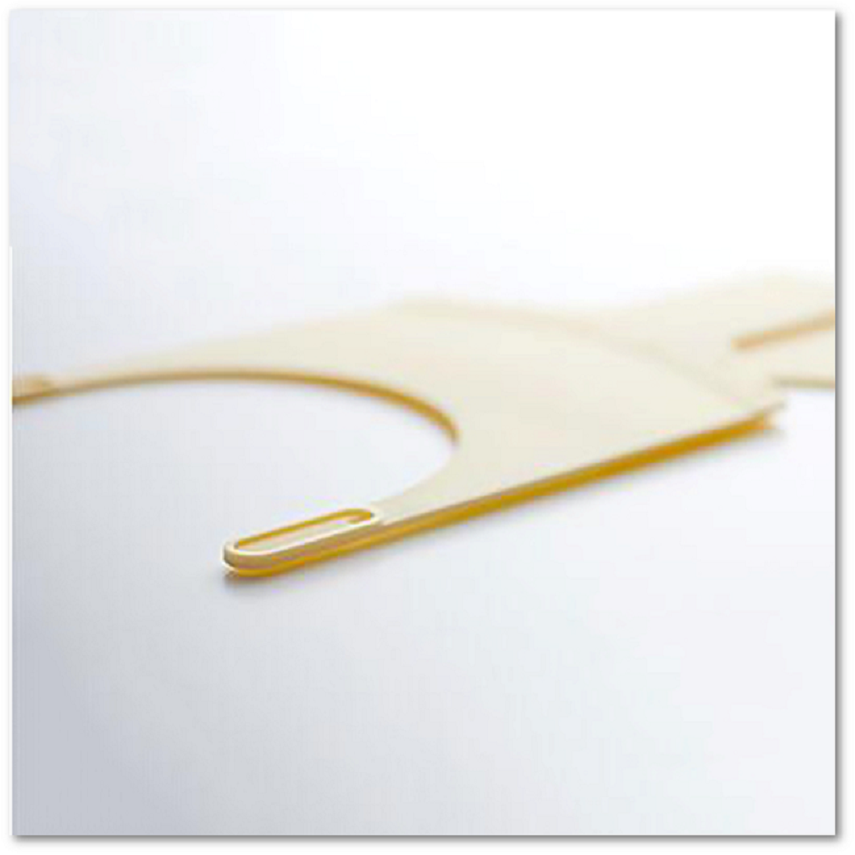

High-purity alumina ceramics including 99.5%, 99.7%, and 99.8% Al₂O₃ are used in specialized environments where material consistency, chemical stability, or reliability is critical.

Key characteristics

▪ Highly stable electrical and thermal behavior

▪ Reduced impurity content

▪ Improved microstructural uniformity

Typical applications

▪ High-reliability electronic substrates

▪ Semiconductor-related components

▪ Medical and analytical equipment

▪ Chemically demanding environments

These grades are generally reserved for applications with strict performance or environmental requirements. Higher purity does not automatically guarantee better mechanical strength, and processing quality remains a decisive factor.

Purity vs Performance in Alumina Ceramic Material Selection

While increasing alumina ceramic purity can enhance certain properties such as electrical insulation stability or chemical resistance, overall performance depends on a combination of purity, microstructure, and manufacturing control.

In many practical cases, a well-processed 96% alumina ceramic may outperform a poorly processed higher-purity material. Effective alumina ceramic material selection therefore requires evaluating both purity level and processing quality within the context of the intended application.

How Mascera Approaches Alumina Grade Selection

At Mascera, alumina ceramic grades are selected based on functional requirements rather than purity values alone. Commonly used alumina grades are recommended according to electrical, thermal, mechanical, and environmental demands, with careful consideration given to manufacturability and long-term reliability.

This application-driven approach ensures that the selected alumina ceramic grade meets performance requirements without unnecessary complexity or cost.

Conclusion

Alumina ceramic grades ranging from 95% to 99.8% represent a spectrum of material solutions rather than a simple performance hierarchy. Each grade serves a distinct role in industrial and electronic applications, offering different balances of reliability, cost efficiency, and functional behavior.Understanding alumina ceramic purity and how different grades are applied in practice enables more informed engineering decisions and more reliable long-term outcomes.