Thermal Conductivity of Alumina Ceramic

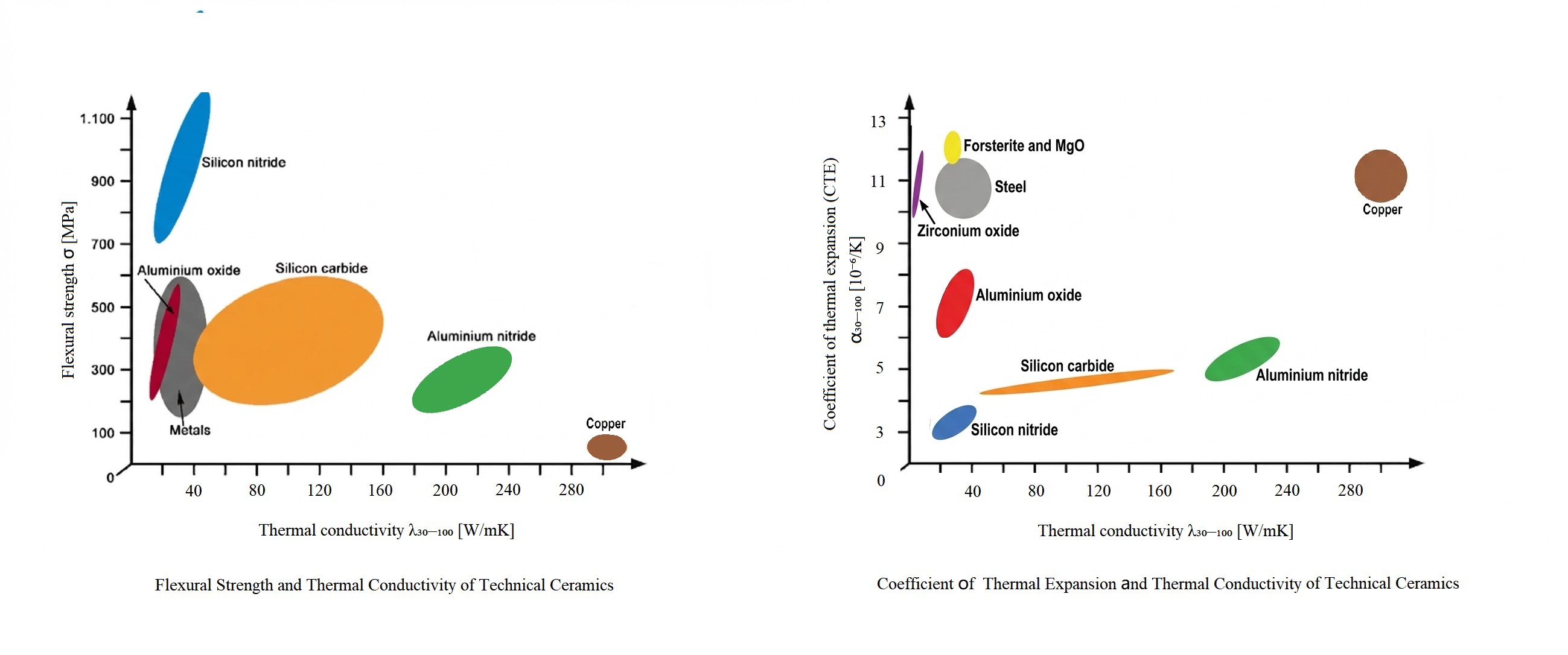

Thermal conductivity is one of the most important physical characteristics of alumina ceramic and a key factor in its widespread use across electronic, electrical, and high-temperature industrial applications. While alumina ceramic is not considered a high thermal conductivity material, it provides a reliable and well-balanced combination of heat transfer capability, electrical insulation, mechanical stability, and cost efficiency.

Understanding the thermal conductivity of alumina ceramic—and the factors that influence it—is essential for proper material selection and effective thermal design.

Note: This technical analysis is part of our “Everything You Need to Know About Alumina Ceramic” series. For its complementary electrical behavior, please refer to our article on Electrical Insulation Properties of Alumina Ceramic.

How Heat Is Conducted in Alumina Ceramic

Heat transfer in alumina ceramic occurs primarily through lattice vibrations, commonly referred to as phonon transport. Because alumina is an electrically insulating oxide ceramic, free electrons do not contribute significantly to thermal conduction. As a result, heat transfer in alumina ceramic is governed mainly by crystal structure, grain boundaries, and overall microstructural integrity.

Compared with metals, alumina ceramic exhibits lower thermal conductivity due to phonon scattering at grain boundaries and defects. However, unlike polymers and many glass materials, alumina ceramic maintains stable thermal behavior at elevated temperatures and does not soften, degrade, or lose structural integrity under continuous heat exposure.

Typical Thermal Conductivity Range of Alumina Ceramic

The thermal conductivity of alumina ceramic is not a single fixed value. It varies depending on material purity, grain structure, and manufacturing quality.

In general, commonly used alumina grades exhibit the following characteristics:

Alumina Purity | Thermal Conductivity (W/m·K) | Application Focus |

95–96% Al₂O₃ | 18–24 | Moderate thermal conductivity suitable for general heat dissipation and insulation applications. |

99% Al₂O₃ | ~27 | Improved thermal conductivity due to reduced impurity content and better lattice continuity. |

99.5–99.8% Al₂O₃ | 29–32 | Highest thermal performance within the alumina family for demanding, high-performance designs. |

Rather than being selected for maximum heat dissipation, alumina ceramic is commonly used in applications where thermal conductivity must be balanced with electrical insulation, mechanical stability, manufacturing maturity, and cost efficiency.

Influence of Purity and Microstructure on Thermal Conductivity

Material purity plays an important role in thermal conductivity by influencing phonon scattering mechanisms. Impurities and secondary phases disrupt lattice continuity, increasing thermal resistance and reducing the efficiency of heat flow through Al₂O₃ ceramics.

Microstructural factors are equally critical. Dense alumina ceramics with uniform grain size and minimal porosity provide more continuous thermal pathways, allowing heat to transfer more effectively. In contrast, excessive porosity, microcracks, or non-uniform grain growth can significantly reduce effective thermal conductivity, even in higher-purity materials. For this reason, thermal conductivity should always be evaluated together with processing quality rather than purity alone.

Thermal Conductivity Under Elevated Temperatures

One of the key advantages of alumina ceramic is its predictable behavior under high-temperature conditions. Although thermal conductivity typically decreases gradually as temperature increases—due to enhanced phonon scattering—the material remains structurally stable and continues to transfer heat reliably at temperatures well beyond the limits of polymer-based materials.

This makes alumina ceramic suitable for applications involving:

▶ Continuous high-temperature operation

▶ Repeated thermal cycling

▶ Combined thermal and mechanical loading

In these environments, stable and predictable alumina ceramic thermal properties are often more valuable than achieving the highest possible heat transfer rate.

Design Considerations for Thermal Management

When using alumina ceramic in thermally demanding systems, effective thermal management depends on more than material selection alone. Key design considerations include:

▶ Component thickness and geometry

▶ Surface contact quality and interface thermal resistance

▶ Mounting methods and mechanical constraints

▶ Interaction with adjacent conductive or insulating materials

Because alumina ceramic is rigid and brittle, improper thermal design—such as steep temperature gradients or constrained thermal expansion—can introduce stresses that affect mechanical integrity. Careful integration of material properties and system design is therefore essential to ensure both thermal and structural reliability.

Interpreting Thermal Performance in Practice

In practical engineering applications, alumina ceramic is valued not for maximum heat transfer, but for its versatility and predictability. It provides a stable thermal pathway while maintaining high electrical insulation and mechanical strength, making it suitable for long-term operation in demanding environments.

When material purity, microstructural quality, and application-specific operating conditions are properly considered, alumina ceramic delivers reliable thermal performance across a wide range of industrial and electronic systems.

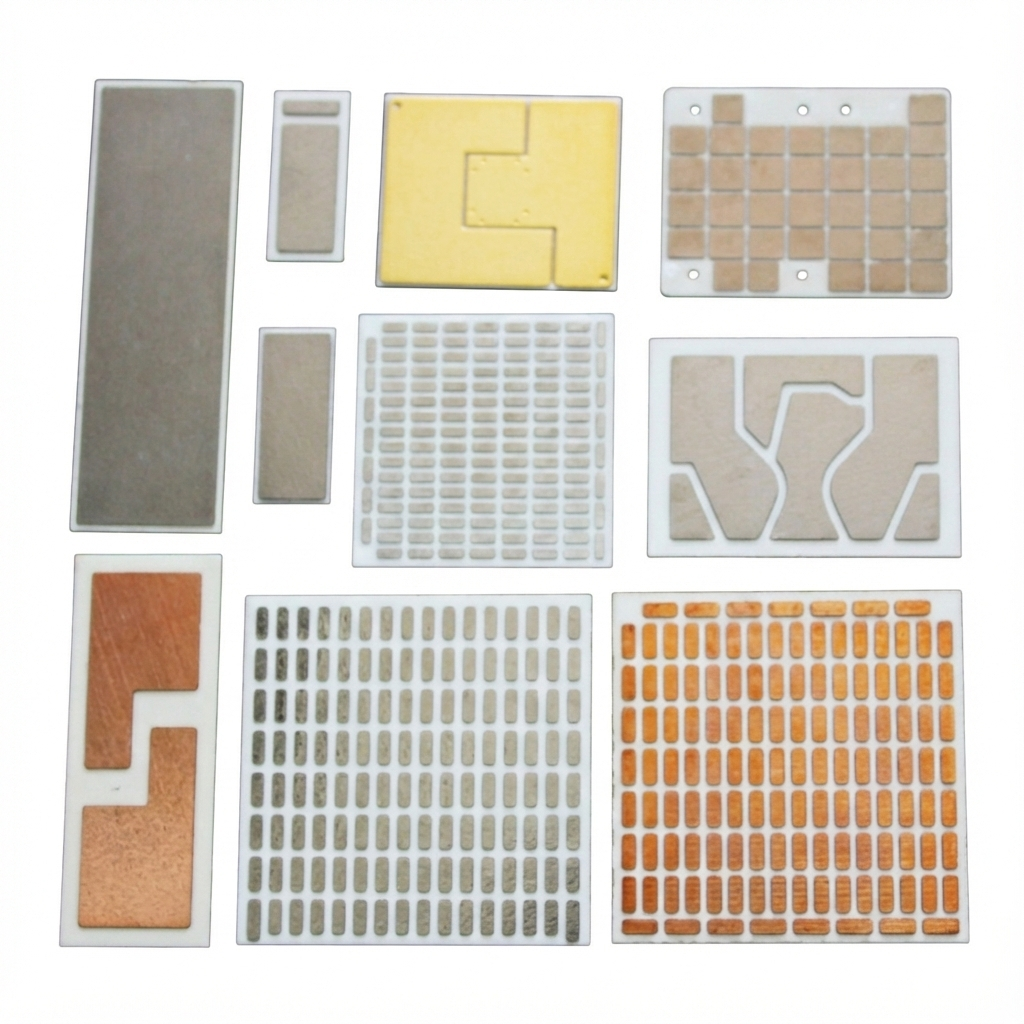

Alumina Ceramic Products To support practical design and manufacturing needs, Mascera offers a comprehensive range of alumina ceramic products, including standard shapes and custom-engineered components. Our product portfolio covers substrates, tubes, rods, plates, and wear parts designed for electronic, thermal, and mechanical applications.

🔗 Explore our alumina ceramic product range