Electrical Insulation Properties of Alumina Ceramic

Electrical insulation is a critical property of alumina ceramic, making it an essential material in electronic, electrical, and high-voltage applications. In many designs, alumina ceramics are selected not primarily for their mechanical strength, but for their ability to provide stable alumina ceramic electrical insulationunder demanding operating conditions. Understanding how alumina ceramic behaves as an electrical insulator—and what factors influence its performance—is essential for correct material selection and reliable long-term operation.

This article provides a focused discussion on the electrical insulation properties of alumina ceramic. For a broader overview of its mechanical and thermal characteristics, please refer to our pillar page: Everything You Need to Know About Alumina Ceramic.

Why Alumina Ceramic Is Widely Used as an Electrical Insulator

The insulating capability of alumina ceramic stems from its atomic structure, which is characterized by strong ionic bonding and a wide electronic band gap. This structure severely restricts the movement of free charge carriers, allowing alumina ceramic to function reliably as an alumina ceramic electrical insulator, even under elevated temperatures and intense electrical fields.

In practical engineering applications, alumina ceramics are widely used to electrically isolate conductive components while simultaneously providing:

▶ Mechanical support, maintaining dimensional stability under load.

▶ Thermal stability, enabling operation in high-temperature environments.

▶ Chemical inertness, preventing surface degradation that could compromise insulation.

Key Electrical Properties of Alumina Ceramic

When evaluating alumina ceramic electrical insulation performance, three core parameters are typically considered: volume resistivity, dielectric strength, and dielectric constant.

1.High Volume Resistivity

Volume resistivity reflects a material’s resistance to leakage current through its bulk. Alumina ceramics exhibit exceptionally high resistivity, typically on the order of 10¹⁴ Ω·cm at room temperature. Unlike polymer-based insulators, alumina ceramic maintains stable resistivity as temperature increases, making it suitable for power electronics and high-temperature electrical systems.

2. Dielectric Strength

Dielectric strength describes the maximum electric field a material can withstand before electrical breakdown occurs. Dense alumina ceramics commonly provide dielectric strength values in the range of 15–22 kV/mm, allowing compact designs with thinner insulating layers while maintaining electrical safety.

3. Stable Dielectric Constant

Alumina ceramic typically exhibits a dielectric constant between 9.0 and 10.0, with relatively stable behavior across a wide frequency range. This predictability is especially important for alumina ceramic substrate applications used in RF, microwave, and power electronic assemblies.

Influence of Purity and Microstructure on Electrical Insulation

The electrical insulation performance of alumina ceramic is not a fixed material constant. In industrial practice, it is influenced by alumina purity, microstructural quality, and manufacturing control.To illustrate how purity affects alumina ceramic electrical insulation in real-world applications, the table below summarizes commonly used purity levels and their typical application areas.

| Alumina Purity | Typical Applications | Electrical Insulation Characteristics |

| 95–96% Al₂O₃ | General electrical insulator Sinsulating washers Metallized alumina ceramic substrates | Reliable electrical insulation for standard industrial and electronic applications; Cost-effective and widely used. |

| 99% Al₂O₃ | High-voltage component Power electronics | Improved resistivity and dielectric strength Suitable for higher electrical stress environments |

| 99.6%-99.8% Al₂O₃ | High-reliability electronic substrates,power modules, semiconductor and medical applications | Highly stable electrical insulation with minimal leakage; Preferred for demanding, high-reliability environments |

Alumina grades are selected based on specific application requirements rather than insulation performance alone. As shown above, typical uses range from general industrial insulation to high-reliability electronic systems, each with different expectations for electrical stability and long-term performance.

Beyond purity, microstructural factors such as porosity, grain uniformity, and defect control play a decisive role in insulation reliability. Dense and homogeneous microstructures help minimize localized electrical leakage paths and maintain stable insulation under combined electrical, thermal, and mechanical conditions.

Insulation Stability Under High Temperatures

One of the key advantages of alumina ceramic electrical insulation is its stability at elevated temperatures. While the electrical resistivity of alumina ceramic decreases at extreme temperatures (for example, above 1000 °C), it continues to provide effective insulation in environments where polymers or glass materials would soften, degrade, or become conductive.

As a result, alumina ceramic is widely used for:

▶ Heater supports that electrically isolate heating elements.

▶ Thermocouple protection tubes that prevent electrical interference in temperature measurement systems.

Critical Design Considerations: Thermal and Mechanical Stress

In practical applications, electrical insulation performance cannot be evaluated in isolation. Because alumina ceramic is a rigid and brittle technical ceramic, thermal shock or localized mechanical stress may lead to micro-cracking.

Even when intrinsic material resistivity remains high, physical defects can allow moisture or contaminants to enter the ceramic surface, potentially causing electrical tracking or insulation failure. Proper component design—such as avoiding sharp corners, controlling thermal gradients, and minimizing assembly stress—is therefore essential to preserving long-term alumina ceramic electrical insulation reliability.

Typical Applications Requiring Electrical Insulation

Due to its stable electrical behavior, alumina ceramic is widely applied as an electrical insulator in:

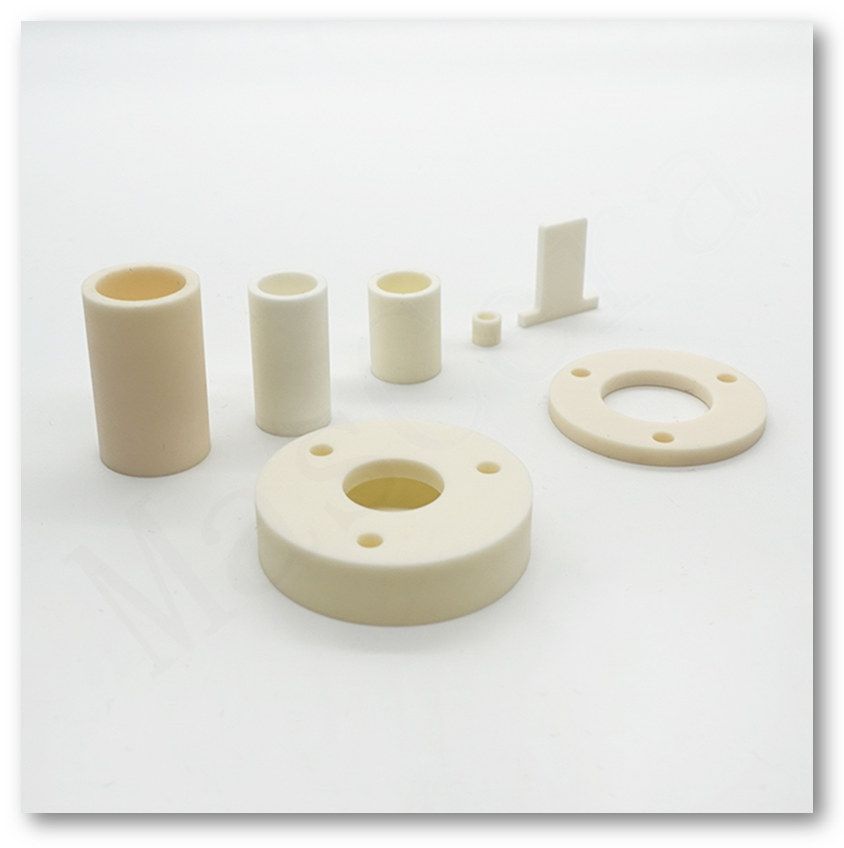

▶ Electrical insulators and spacers for power and vacuum systems

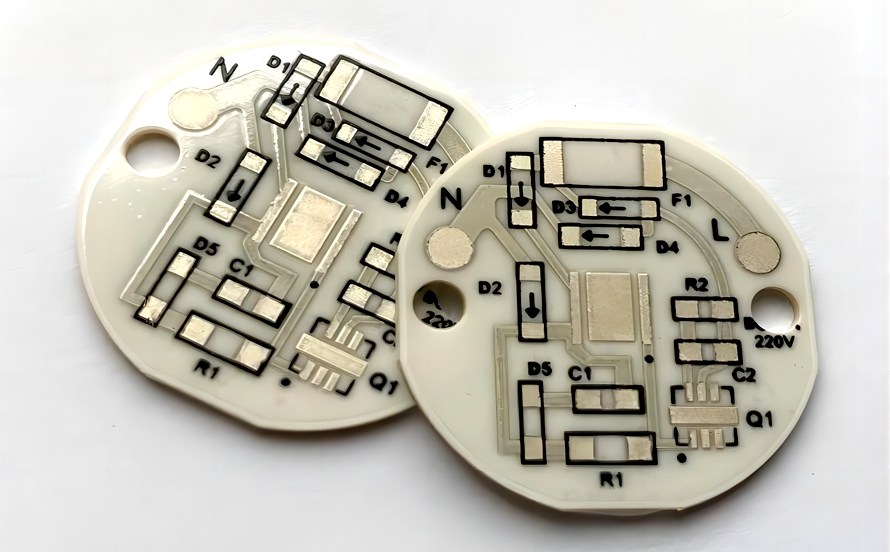

▶ Alumina ceramic substrates for integrated circuits and electronic modules

▶ High-voltage feedthroughs for vacuum and sealed environments

▶ Power electronics requiring electrical isolation combined with thermal management

▶ Spark plug insulators exposed to high voltage and rapid thermal cycling

In these applications, alumina ceramic provides effective electrical isolation while maintaining dimensional stability, chemical resistance, and long-term reliability.

Interpreting Electrical Insulation Performance in Practice

In conclusion, alumina ceramic provides reliable alumina ceramic electrical insulation across a wide range of industrial and electronic applications when its properties are correctly interpreted and applied. Rather than relying on material data alone, engineers must consider material purity, microstructural quality, and application-specific operating conditions, including environmental exposure, temperature limits, and mechanical constraints.When these material and design-related factors are properly addressed, alumina ceramic delivers stable and long-term electrical insulation performance in demanding operating environments.

Mascera offers alumina ceramic components customized to meet specific electrical insulation requirements. Our engineering team supports material selection to help ensure reliable performance across a wide range of industrial and electronic applications.