How to Choose the Right Alumina Ceramic for Your Application

Choosing the right alumina ceramic material is not simply about picking the highest purity grade—it requires aligning application needs, part geometry, and processing feasibility. This article offers a concise and actionable guide to help engineers and buyers make informed decisions, especially when working with Mascera's full range of alumina ceramic grades.

Note: This technical analysis is part of our “Everything You Need to Know About Alumina Ceramic” series. To see how these grades affect specific performance, explore our guides on Electrical Insulation and Thermal Conductivity.

When Purity Matters

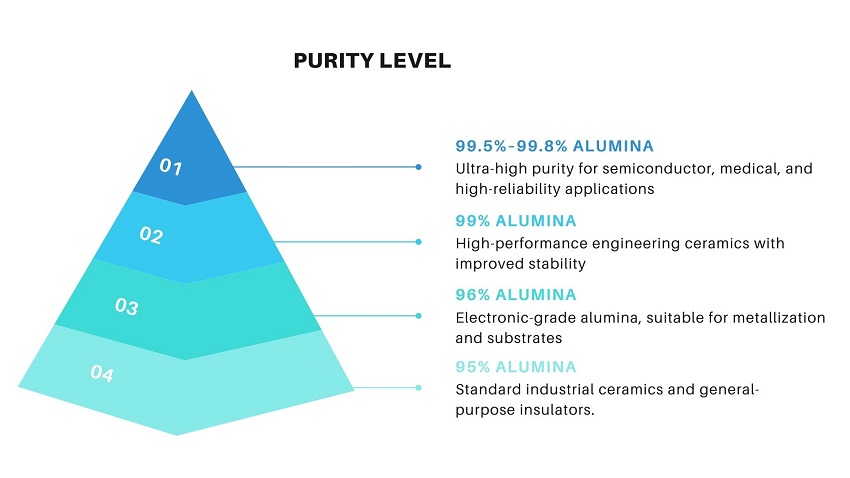

Alumina purity levelstypically range from 95% to 99.8%. While higher purity improves properties like electrical insulation, corrosion resistance, and thermal stability, it isn't always necessary or optimal for every application.

Use high-purity grades (99.5%–99.8%) for critical applications like semiconductors and high-temperature sensors. Lower grades (95%–99%) often deliver the best cost-performance ratio for general structural and insulating parts.

Think in Terms of Application and Geometry

To simplify the selection process, first evaluate the role the part plays:

▪ Electrical insulation

Most grades provide excellent dielectric properties. Choose based on whether metallization is needed.

▪ Wear resistance or load-bearing

95% and 99% grades offer strong mechanical performance and are commonly used for structural parts like rings and guides.

▪ High-temperature exposure

Long tubes or furnace components generally require 99.5% alumina for thermal reliability over length.

▪ Thin sheets or substrates

These are made using tape casting, which limits you to 95% or 99.6% alumina grades.

▪ Custom precision parts

99% alumina is often chosen for its machinability and dimensional stability.

Your application defines the performance required; the shape defines what's manufacturable.

Quick Reference: Common Parts and Recommended Grades

| Part Type / Use Case | Recommended Alumina Grade | Notes |

| Structural rings, sleeves | 95% / 99% | General-purpose, good strength and machinability |

Metallized ceramic components | 95% | Compatible with Mo/Mn metallization |

| Long high-temperature tube | 99.5% | Only grade compatible with extrusion/slip casting for long geometries |

Thin ceramic substrates | 96% / 99.6% | Made by tape casting, used in electronics |

Custom Alumina Ceramic Parts by Mascera

Mascera supports engineers in selecting the right material from our full alumina range—from 95% to 99.8%—based on both technical requirements and manufacturability. We offer:

▪ Application-based grade recommendations

▪ Engineering review of your drawings

▪ Manufacturing of custom alumina ceramic partsincluding tubes, rings, discs, substrates, and more

Need Help Choosing?

If you're unsure which alumina ceramic grade suits your part design or working conditions, Mascera's engineering team can help. Contact us for professional guidance and rapid material matching.

Alumina Ceramic Products To support practical design and manufacturing needs, Mascera offers a comprehensive range of alumina ceramic products, including standard shapes and custom-engineered components. Our product portfolio covers substrates, tubes, rods, plates, and wear parts designed for electronic, thermal, and mechanical applications.

🔗 Explore our alumina ceramic product range