What is the Main Use of Pyrolytic Boron Nitride Ceramics?

Pyrolytic Boron Nitride (PBN) is a high-purity ceramic material synthesized through chemical vapor deposition (CVD). Characterized by extremely low impurity levels, exceptional chemical inertness, excellent electrical insulation, and outstanding high-temperature resistance, Pyrolytic Boron Nitride differs from conventional hot-pressed boron nitride in that it forms through layer-by-layer high-temperature vapor reactions. This process results in a dense, highly isotropic structure with a purity exceeding 99.99%.

exceptional chemical inertness, excellent electrical insulation, and outstanding high-temperature resistance, Pyrolytic Boron Nitride differs from conventional hot-pressed boron nitride in that it forms through layer-by-layer high-temperature vapor reactions. This process results in a dense, highly isotropic structure with a purity exceeding 99.99%.

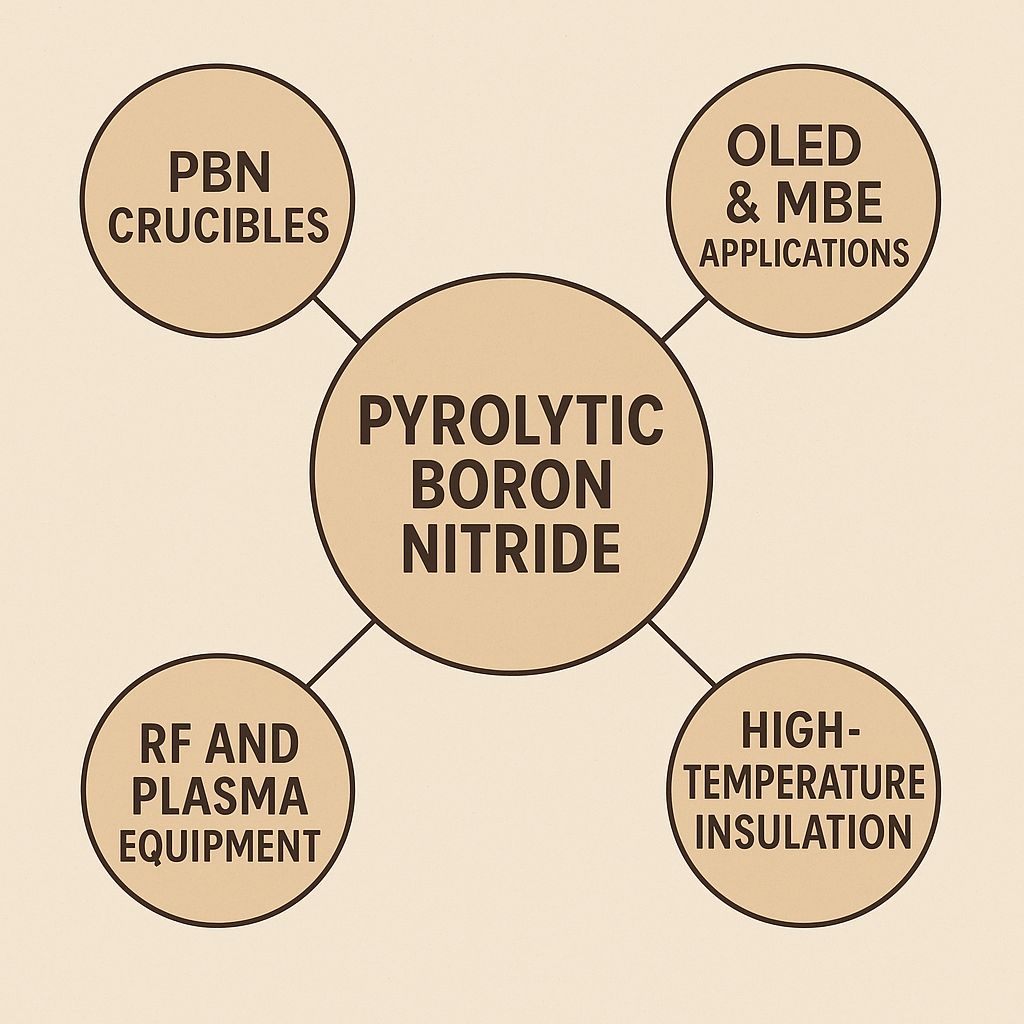

Thanks to its unique properties, Pyrolytic Boron Nitride is widely used in electronics, semiconductors, optoelectronics, vacuum equipment, and high-temperature experimental systems. It plays an irreplaceable role in many critical processes. Below are the main application areas of Pyrolytic Boron Nitride:

PBN Crucibles for III-V Compound Semiconductor Crystal Growth

PBN crucibles are indispensable in the growth of compound semiconductor crystals such as GaAs, InP, and GaP. PBN crucibles materials are foundational for optoelectronic devices, RF chips, and high-speed integrated circuits. Pyrolytic Boron Nitride's ultra-low volatility and superior thermal stability ensure no reactions with molten materials during high-temperature processing, leading to enhanced crystal quality and yield. Additionally, the smooth surface of PBN crucibles minimizes material adhesion, reducing cleaning costs and prolonging service life. PBN crucibles have become the standard choice in many crystal growth systems due to their excellent purity and thermal performance. For many compound semiconductor applications, PBN crucibles provide unmatched performance.

OLED Evaporation and Molecular Beam Epitaxy (MBE)

In high-vacuum environments such as OLED manufacturing and MBE systems, Pyrolytic Boron Nitride is the preferred material for evaporation boats and crucibles. These systems demand ultra-high material purity and excellent thermal endurance. PBN crucibles withstand temperatures over 1800°C and release virtually no volatile contaminants under vacuum, ensuring high uniformity and precision in thin-film deposition. The use of Pyrolytic Boron Nitride enables impurity control at ppb levels in high-precision applications like blue OLEDs and organic lasers. In both OLED and MBE systems, PBN crucibles help maintain material purity and deposition stability.

High-Temperature Insulation Components in Vacuum Systems

In high-temperature vacuum furnaces, Pyrolytic Boron Nitride is widely used for heater insulators, hot-zone structural parts, nozzles, and flow guides. With its extremely low thermal conductivity and high volume resistivity, Pyrolytic Boron Nitride serves as an excellent high-temperature insulation material. Even above 2000°C in vacuum or inert atmospheres, PBN maintains structural integrity and insulation performance without decomposition or degradation. Additionally, PBN is often combined with graphite in thermal systems, where it is used as a coating to improve oxidation resistance and extend the life of graphite components. In such systems, high-temperature insulation is critical to maintaining process stability, and Pyrolytic Boron Nitride provides reliable performance.

Electrical Insulation in RF and Plasma Equipment

In RF, microwave systems, plasma generators, and ion sources, materials must exhibit stable electrical and thermal properties. Pyrolytic Boron Nitride, with its low dielectric constant, low dielectric loss, and stable thermal expansion, serves as an ideal high-temperature insulation material and structural support in high-frequency, high-temperature environments. Its volume resistivity exceeds 10^14 Ω·cm at room temperature, making it a preferred material for insulating components in high-frequency power systems. In high-power plasma etching machines, magnetron sputtering equipment, and ion beam systems, Pyrolytic Boron Nitride also serves as a chemically resistant plasma-facing material, offering exceptional chemical stability and reliable structural performance under thermal stress. The ability of Pyrolytic Boron Nitride to act as both electrical insulator and high-temperature insulation component underscores its value in modern plasma equipment.

Crucibles for Metallurgical Experiments and Functional Material Processing

PBN crucibles are widely used in alloy melting, rare metal refining, and advanced material synthesis. They resist high temperatures and aggressive chemical environments such as fluorides, sulfides, and borides. PBN crucibles remain intact even under extreme thermal shock conditions, showing minimal cracking or deformation. Their smooth surfaces, thermal expansion compatibility with glass ceramics, and ease of high-purity material recovery make them ideal for thermal analysis and thermogravimetric analysis in research labs. The combination of chemical resistance and high-temperature insulation makes Pyrolytic Boron Nitride a top choice for crucibles in demanding experimental environments. PBN crucibles offer both durability and purity, making them ideal for laboratories and industrial research settings.

Pyrolytic Boron Nitride stands out in modern high-temperature and ultra-high vacuum processes due to its superior thermal stability, electrical insulation, chemical inertness, and cleanliness. Whether in PBN crucibles, high-temperature insulation systems, or precision electronic manufacturing, Pyrolytic Boron Nitride meets the demanding requirements of extreme applications. With its ability to serve as a critical high-temperature insulation material and its irreplaceable role in PBN crucibles, Pyrolytic Boron Nitride continues to be a vital material solution in next-generation high-tech industries. PBN crucibles and high-temperature insulation applications will remain at the forefront of Pyrolytic Boron Nitride's relevance in advanced materials engineering.