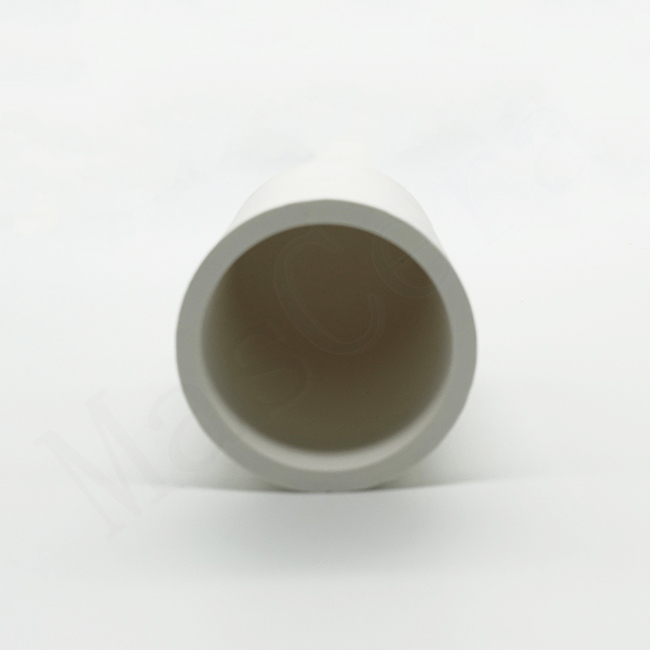

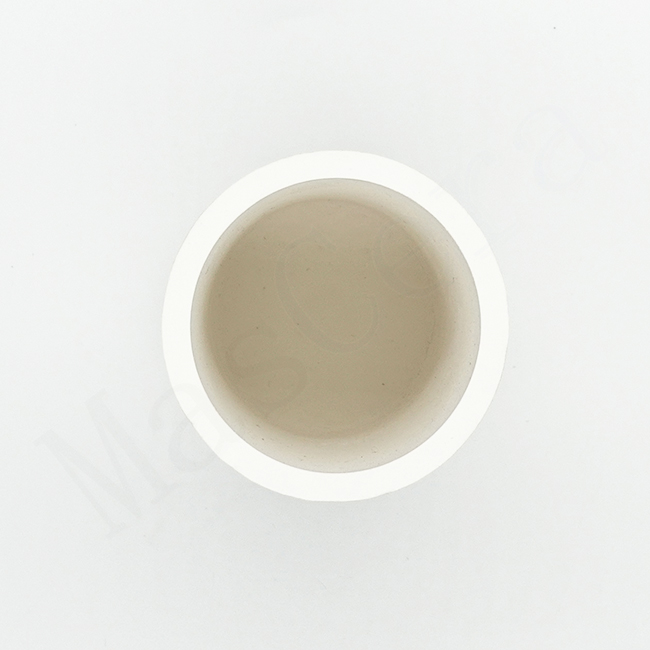

High purity ZrO2 zirconia ceramic crucible

- MSJ/ZR-016

- zirconia ceramic

- customized

- 5 pcs per type

- induction melting/oxidising or vacuum atmospheres/precious metals or superalloys

Mascera produces a variety of crucibles based on stable zirconia. The performance of the finished products depends on the manufacturing method and the choice of stabilizing medium. Calcium oxide, magnesium oxide, and yttrium oxide are used as stabilizers, each with different thermal characteristics. The team can assist customers in selecting the appropriate zirconia crucible based on specific usage scenarios or produce products according to customer drawings and requirements.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

High-purity zirconia (ZrO2) ceramic crucibles renowned for their exceptional durability, chemical resistance, and high-temperature tolerance. Zirconia crucibles can withstand temperatures of up to 2000°C, making them ideal for applications that require temperatures exceeding the capabilities of alumina crucibles (withstand temperature of 1600°C). They are particularly well-suited for tasks like melting precious metals and superalloys, which have melting points surpassing 1800°C.

Mascera produces a variety of crucibles based on stable zirconia. The performance of the finished products depends on the manufacturing method and the choice of stabilizing medium. Calcium oxide, magnesium oxide, and yttrium oxide are used as stabilizers, each with different thermal characteristics. The team can assist customers in selecting the appropriate zirconia crucible based on specific usage scenarios or produce products according to customer drawings and requirements.

Main properties of zirconia ceramic crucibles

1.Can be used up to 2000°C

2.Very good resistance to thermal shock

3.Erosion resistant

4.Very low thermal expansion

5.Resistant to wetness from molten metals

Applications of zirconia ceramic crucibles include

1.Crucibles for induction melting

2.Crucibles for use in oxidising or vacuum atmospheres

3.Crucibles for precious metals or superalloys

Zirconia ceramic crucibles suitable for sintering and smelting

1.Platinum/Platinum group metals

2.Nickel based super alloys

3.Cobalt based super alloys

4.Uranium

5.Sputter material for hard disk drives

Notes for use:

1.Before initial use, it is recommended to place the crucible in a 105°C oven for 2 hours to eliminate any moisture.

2. it is important to avoid rapid heating or cooling beyond a rate of 5°C per minute.

Also Available from Mascera

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |