Classification and Application of Advanced Ceramics

According to the concepts and applications of ceramics, ceramic products can be classified into two main categories: conventional ceramics (traditional ceramics) and advanced ceramics. Conventional ceramics refer to various products made from clay and its natural minerals through processes such as crushing, mixing, shaping, and firing. Advanced ceramics, on the other hand, are characterized by the use of highly selected or synthesized raw materials with precise control of chemical composition, processed using manufacturing techniques conducive to control, allowing for structural design, and exhibiting superior characteristics.

Advanced ceramics can be further classified into two types based on their characteristics: structural ceramics and functional ceramics.

1、Structural Ceramics

Structural ceramics refer to ceramics that can be used as engineering structural materials, broadly categorized into oxide-based, non-oxide-based, and ceramic matrix composites for structural use.

Examples of structural ceramics include cutting tools, molds, wear-resistant parts, pump and valve components, engine parts, heat exchangers, and armor. Major materials used include silicon nitride (Si3N4), silicon carbide (SiC), zirconia (ZrO2), alumina (Al2O3), among others.

2、Functional Ceramics

Functional ceramics are knowledge and technology-intensive products with a wide variety. These materials possess various excellent functions such as microwave dielectric properties, gas sensitivity, superconductivity, resistivity gradient properties, ferroelectric properties and phase transition behaviors, multilayer driveability, and relaxation properties, among others, making their applications extremely diverse.

(1)Electronic Insulation Materials

The commonly used electronic insulation material internationally is Al2O3. In recent years, new electronic insulation materials such as AlN ceramics have emerged, possessing excellent properties such as high strength, high insulation, low dielectric constant, and high thermal conductivity. Their thermal expansion coefficient can match with single crystal silicon, and they are mainly used as heat dissipation substrates for large-scale integrated circuits and power module circuits.

(2)Ceramic Dielectric Materials

Ceramic capacitor dielectric materials used for tuning circuits and protecting logic and memory units are mostly based on BaTiO3. Additionally, there are high dielectric constant composite perovskite materials, with the development of high dielectric materials where the dielectric constant can reach up to 10^5 at a frequency of 10^5Hz, several times or even tens of times higher than conventional ceramic capacitors.

(3)Piezoelectric Ceramic Materials

Commonly used piezoelectric devices include sensors, gas igniters, alarms, audio devices, medical diagnostic equipment, and communication devices. The typical piezoelectric material is PZT, and new types include high-sensitivity, high-stability piezoelectric ceramic materials, electrostrictive ceramic materials, and pyroelectric ceramic materials.

(4)Magnetic Ceramic Materials

Magnetic ceramic materials can be divided into hard magnetic and soft magnetic materials. Hard magnetic materials are not easily magnetized or demagnetized and are represented by ferrite magnets and rare earth magnets, mainly used for magnets and magnetic storage components. Soft magnetic materials are easily magnetized and demagnetized, with changeable magnetic field directions, mainly used for electronic components responding to alternating magnetic fields.

(5)Superconducting Ceramic Materials

Since the significant breakthroughs in the research of superconducting ceramics in the 1980s, research and applications of high-temperature superconducting ceramic materials have attracted much attention. The application of high-temperature superconducting materials is developing towards high-current applications, electronics, and anti-magnetic properties.

(6)Antimicrobial Ceramic Materials

Antimicrobial ceramic materials are a new generation of functional materials that have emerged with the development of science and social civilization. Inorganic antimicrobial agents can be classified into three categories based on their mechanisms of action on microorganisms: one is mainly fixed on inorganic materials carriers such as zeolites, hydroxyapatite, silica gel, and glass through physical adsorption or ion exchange, containing antimicrobial metals or their ions such as silver, copper, and zinc. The second category is titanium dioxide particle photocatalytic antimicrobial agents, where titanium dioxide can convert oxygen molecules into active oxygen under light, generating active oxygen radicals in water to exhibit antibacterial and bactericidal effects. The third category is antimicrobial materials with far-infrared radiation functionality. Far-infrared radiation has limited antimicrobial effects, so these materials must be used in conjunction with the first two types of materials to have better application value.

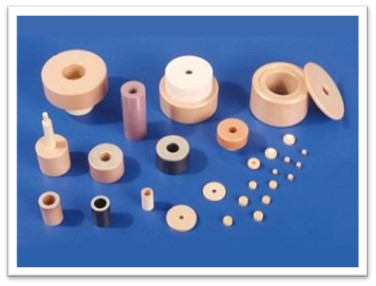

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.