Characteristics and applications of aluminum nitride ceramics

Aluminum nitride (AlN) is a non-oxide ceramic material primarily composed of nitrogen and aluminum. It is a solid nitride of aluminum, exhibiting a high thermal conductivity exceeding 170W/mK and excellent electrical insulation properties. Typically manufactured through powder sintering or hot pressing methods.

Aluminum nitride (AlN) is a non-oxide ceramic material primarily composed of nitrogen and aluminum. It is a solid nitride of aluminum, exhibiting a high thermal conductivity exceeding 170W/mK and excellent electrical insulation properties. Typically manufactured through powder sintering or hot pressing methods.

1、Characteristics of Aluminum Nitride Ceramic:

Aluminum nitride ceramic as a novel ceramic material with excellent comprehensive performance, possesses numerous outstanding characteristics:

(1) High Thermal Conductivity

With a thermal conductivity surpassing 170W/mK, comparable to beryllium oxide (BeO) and silicon carbide (SiC).

(2) Similar Thermal Expansion to Silicon

Aluminum nitride has a thermal expansion coefficient of 4.510^-6℃, akin to silicon's thermal expansion coefficient (3.5-410^-6℃).

(3) Excellent Dielectric Performance—Volume Resistivity, Dielectric Constant, Dielectric Loss, and Dielectric Strength

The electrical properties of aluminum nitride include dielectric constant, dielectric loss, volume resistivity, and dielectric strength, making it an outstanding insulating material.

(4) Good Mechanical Properties

It exhibits higher flexural strength compared to alumina (Al2O3) and beryllium oxide (BeO) ceramics.

(5) Transparent Characteristics

With a crystal structure resembling sapphire, aluminum nitride possesses decent transparency.

(6) Non-toxic

Unlike beryllium oxide (BeO), aluminum nitride is non-toxic.

2、Applications of Aluminum Nitride Ceramic:

(1) Electronic Packaging Substrate Material

High resistivity, high thermal conductivity, and low dielectric constant are fundamental requirements for electronic packaging substrates. Aluminum nitride ceramics are considered ideal substrate materials due to their excellent insulation, chemical stability, high thermal conductivity, and good high-frequency characteristics.

(2) Transparent Ceramic Materials

Pure aluminum nitride ceramics are colorless transparent crystals with excellent optical properties, suitable for manufacturing high-temperature infrared windows and heat-resistant coatings for electronic optical device equipment, thus finding applications in military industries.

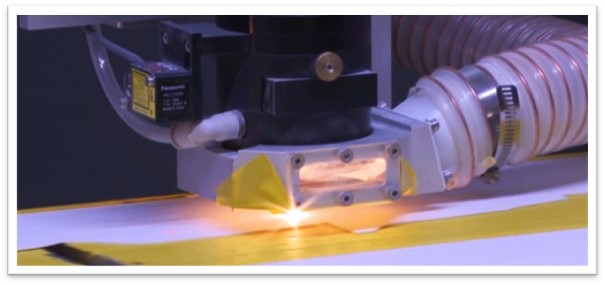

(3) Materials in Mechanical Industries

With high hardness and high-temperature strength, aluminum nitride ceramics can be used for cutting tools, grinding wheels, drawing dies, tool materials, and raw materials for metal ceramic materials. They also exhibit excellent wear resistance, suitable for wear-resistant parts.

Due to its characteristics such as non-wettability with metals like aluminum and calcium, aluminum nitride can be used in crucibles, protective tubes, and casting molds. It can also be employed in immersion thermocouple protection tubes, as it does not adhere to molten metal, allowing continuous use for over 3000 hours at temperatures between 800 to 1000°C without corrosion.

Additionally, replacing glass with aluminum nitride crucibles for the synthesis of gallium arsenide semiconductors can eliminate silicon contamination, resulting in high-purity gallium arsenide.

(5) Heat Shock and Heat Exchange Materials

Aluminum nitride ceramics are less affected by temperature changes and possess relatively high thermal conductivity and low thermal expansion coefficients, making them excellent materials for heat shock and heat exchange applications, such as in gas turbine heat exchangers.

Aluminum nitride ceramic materials have broad application prospects and extensive potential markets in various fields such as electronics, electrical power, locomotives, aviation and aerospace, defense and military industries, telecommunications, and numerous industrial sectors. With the continuous advancement and innovation in technology, aluminum nitride ceramics will further expand their applications and developments in various fields.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.