Comparative Analysis of Corundum, Alumina, Cordierite, Mullite, and Corundum Mullite Refractory Ceramics

Refractory ceramics are foundational in high-temperature, structural, and thermal insulation applications. Among the many types available, five key refractory ceramics stand out for their widespread industrial use and contrasting performance: Corundum, Alumina (Al2O3), Cordierite, Mullite, and Corundum Mullite.

These refractory ceramics are frequently encountered in industries such as metallurgy, electronics, energy, and kiln design. While Refractory Ceramics compositions differ, they are often considered together because they address similar challenges: resistance to heat, thermal shock resistance, mechanical stress, and chemical exposure. By comparing these ceramics side by side, engineers and designers can make informed material selections based on the specific demands of their applications—whether it’s extreme hardness, thermal shock resistance, cost-efficiency, or structural strength at high temperatures.

This article explores Refractory Ceramics differences in chemistry, thermal shock resistance, mechanical properties, and ideal applications, with a focus on optimizing the use of refractory ceramics like Al2O3 and Corundum Mullite.

1. Corundum (Single-Crystal Alpha Al2O3)

Chemical Formula: α-Al2O3 Structure: Trigonal (Hexagonal close-packed oxygen lattice with Al3+ in octahedral sites)

Structure: Trigonal (Hexagonal close-packed oxygen lattice with Al3+ in octahedral sites)

Corundum is the crystalline form of pure Al2O3, known for its extreme hardness (Mohs 9), second only to diamond. It occurs naturally as gemstones such as ruby and sapphire and is also synthetically produced for industrial abrasives and high-performance refractory ceramics.

Key Features:

Highest hardness among oxides

Excellent thermal stability and chemical resistance

Typically transparent or colored (gem-quality)

Applications:

Abrasive materials (grinding wheels)

Optical windows

High-strength wear parts

Extreme-duty refractory ceramics

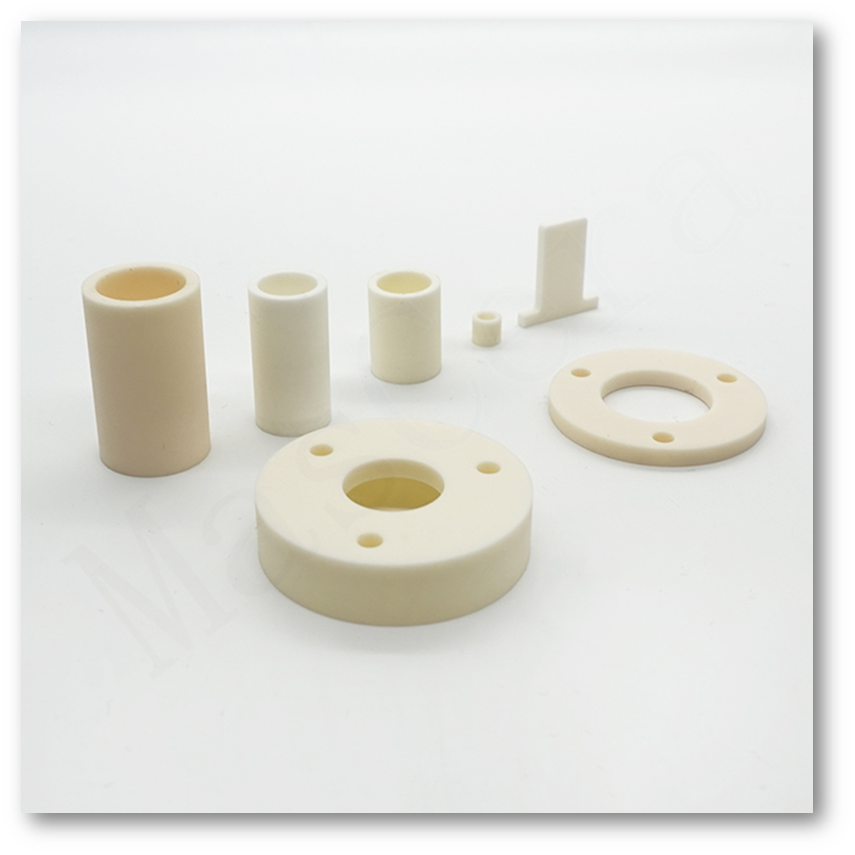

2. Alumina (Polycrystalline Al2O3)

Chemical Formula: Al2O3

Structure: Typically α-phase (same as corundum), but in polycrystalline form

Alumina, or Al2O3, is one of the most widely used refractory ceramics. While it shares the same chemistry as corundum, it is typically sintered as a polycrystalline body, meaning it contains numerous small grains with random orientations.

Key Features:

High hardness and mechanical strength

Excellent dielectric properties

High thermal conductivity (compared to other ceramics)

Good thermal shock resistance for a dense ceramic

Applications:

Furnace components

Refractory linings

Cutting tools

Structural insulators made from Al2O3

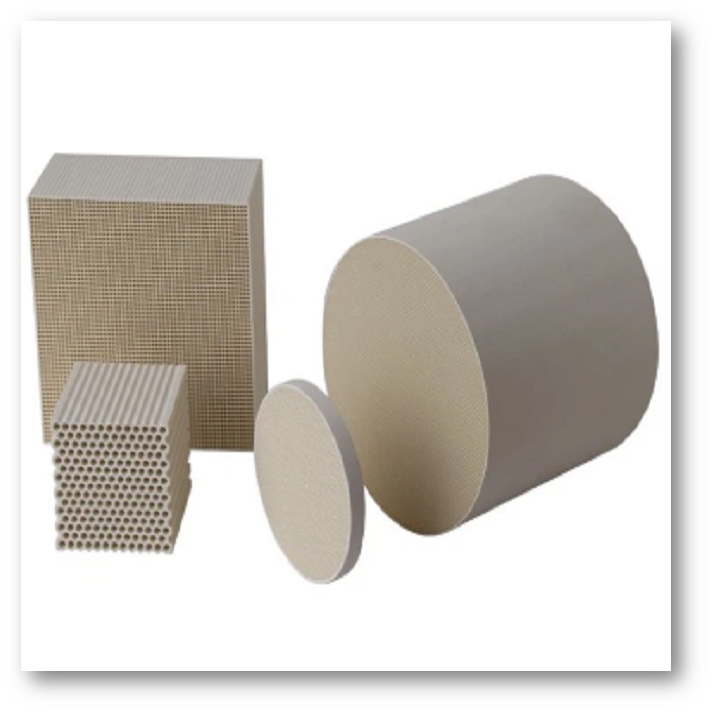

3. Cordierite

Chemical Formula: Mg2Al4Si5O18

Structure: Orthorhombic

Cordierite is valued for its exceptionally low coefficient of thermal expansion (CTE), making it ideal for applications where rapid temperature changes occur. However, its mechanical strength and hardness are relatively low.

Key Features:

Outstanding thermal shock resistance

Low thermal expansion (~2 x10^-6/°C)

Lightweight and low density

Applications:

Kiln furniture

Automotive catalytic converter supports

Thermal insulators

4. Mullite

Chemical Formula: 3Al2O3·2SiO2 Structure: Orthorhombic, needle-like crystal morphology

Structure: Orthorhombic, needle-like crystal morphology

Mullite offers a great balance between strength, thermal stability, and cost. It is naturally formed at high temperatures and is used extensively in refractory ceramics such as linings and structural components.

Key Features:

High thermal shock resistance

Good creep resistance at elevated temperatures

Moderate density and strength

Applications:

Furnace insulation

Kiln supports

High-temperature refractory ceramics using Al2O3-SiO2 systems

5. Corundum Mullite (Al2O3-Mullite Composite)

Chemical Composition: Typically 72% to 90% Al2O3 with the remainder being mullite phase

Structure: Composite of corundum and mullite phases (interlocked grains)

Corundum Mullite combines the high-temperature strength of Al2O3 with the excellent thermal shock resistance of mullite. It is a widely used refractory ceramic in high-temperature applications where mechanical load, thermal shock resistance, and chemical attack are present.

Key Features:

High refractoriness (>1700°C)

Excellent slag resistance and dimensional stability

Balanced mechanical and thermal shock resistance

Applications:

Furnace tubes and liners

Burner nozzles and radiant heater supports

Hot air ducts and kiln components

High-performance refractory ceramics

Comparative Analysis Of Refractory Ceramics

Chemical Properties

The foundation of each ceramic's superior performance is its chemical composition. Corundum and Alumina, both primarily composed of aluminum oxide (Al2O3), offer exceptional hardness and thermal properties, with Corundum showcasing a hardness of 9 on the Mohs scale and Alumina slightly lower at 8.5–9.

Corundum Mullite, a composite material consisting of 72–90% Al2O3 and mullite phase, combines the chemical purity of alumina with the structural benefits of mullite. This synergy delivers both high-temperature performance and enhanced thermal shock resistance.

This chemical purity translates to outstanding durability and efficiency in applications such as abrasives and electronics. Cordierite (Mg2Al4Si5O18) and Mullite (3Al2O3·2SiO2), with their unique compositions, provide specialized properties like exceptional thermal shock resistance for Cordierite and high-temperature stability for Mullite, making them indispensable in their respective application domains.

Physical Properties

The hardness and durability of these ceramics underscore their application versatility. Corundum, with its Mohs hardness of 9, is unmatched in abrasion resistance, ideal for cutting tools and protective coatings. Alumina, closely following with a hardness of 8.5–9, excels in high-temperature environments.

Corundum Mullite exhibits a balanced hardness (8–8.5 Mohs), making it suitable for applications that demand both mechanical durability and resistance to thermal stress, such as furnace tubes and burner nozzles.

Cordierite's thermal shock resistance is attributed to its moderate hardness (7–7.5) and low thermal expansion coefficient (2.0×10⁻⁶/°C), ideal for kiln furniture and automotive catalyst supports. Mullite combines strength (6–7 Mohs hardness) with excellent thermal properties, suitable for refractory linings and aerospace engineering.

Thermal Properties

Corundum and Alumina demonstrate superior thermal stability, with melting points at 2050°C and 2072°C, respectively, making them suitable for high-temperature processing. Corundum Mullite also performs excellently in high-temperature environments, maintaining structural integrity up to 1700°C while resisting thermal cycling damage.

Cordierite stands out for its excellent thermal shock resistance, attributed to its low thermal expansion coefficient (2.0×10⁻⁶/°C), beneficial in applications experiencing rapid temperature changes. Mullite, with its melting point at 1840°C and a thermal expansion coefficient of 5.3×10⁻⁶/°C, offers balanced performance in high-temperature environments.

Mechanical Properties

The strength and toughness of these materials are pivotal for their use in demanding applications. Corundum's high compressive strength, supported by its Mohs hardness of 9, is optimal for abrasive environments. Alumina's mechanical strength makes it a choice material for structural components where rigidity and durability are required.

Corundum Mullite provides high mechanical strength while maintaining good thermal shock resistance, making it ideal for structural parts in furnaces, hot air systems, and heat treatment equipment.

Cordierite's unique combination of thermal shock resistance and mechanical strength caters to applications with thermal cycling, while Mullite's high-temperature strength supports its use in structural and aerospace applications. Corundum's high compressive strength, supported by its Mohs hardness of 9, is optimal for abrasive environments. Alumina's mechanical strength makes it a choice material for structural components where rigidity and durability are required. Cordierite's unique combination of thermal shock resistance and mechanical strength caters to applications with thermal cycling, while Mullite's high-temperature strength supports its use in structural and aerospace applications.

Applications

The specific properties of Corundum, Alumina, Cordierite, Mullite, and Corundum Mullite tailor them to distinct applications. Corundum's hardness makes it ideal for abrasives and cutting tools.

Alumina's electrical insulation properties suit it for electronic substrates and biomedical devices. Cordierite's thermal shock resistance is perfect for kiln furniture and heat exchangers, whereas Mullite's high-temperature stability is crucial for refractory linings and aerospace components.

Corundum Mullite's unique composite performance makes it an excellent material for burner nozzles, radiant heater supports, and furnace liners where both mechanical stress and thermal cycling are present.

Matching these materials to their applications ensures products that meet the highest standards of performance and durability.

The table below provides a succinct overview of each ceramic's key attributes, aiding in understanding their unique advantages and suitability for various applications.

Comparison Table Of Refractory Ceramics

| Property | Corundum | Alumina | Cordierite | Mullite | Corundum Mullite |

|---|---|---|---|---|---|

| Chemical Formula | α‑Al2O3 single crystal | Polycrystalline α‑Al2O3 | Mg2Al4Si5O18 | 3Al2O3·2SiO2 | Al2O3 + Mullite phase |

| Mohs Hardness | 9 | 8.5–9 | 6–7 | 6–7 | 8–8.5 |

| Max Temp (approx.) | 1900°C | 1700°C | 1300°C | 1600°C | 1700°C |

| Thermal Expansion (CTE) | Medium | Medium | Very Low | Medium | Medium-Low |

| Thermal Shock Resistance | Moderate | Good | Excellent | Excellent | Very Good |

| Mechanical Strength | Very High | High | Low | Moderate | High |

| Cost | Very High | Medium | Low | Low | Medium |

Each refractory ceramics material serves a unique purpose based on its strengths:

▶ Corundum is best for extreme wear and hardness

▶ Al2O3 (Alumina) is a general-purpose high-temperature ceramic

▶ Cordierite is ideal where thermal shock resistance is critical

▶ Mullite offers a thermal-mechanical balance

▶ Corundum Mullite is perfect for demanding high-temperature structural applications requiring thermal shock resistance

Choosing the right refractory ceramic depends on the operating environment, thermal requirements, and mechanical demands. Understanding these differences ensures optimal material selection for industrial performance, particularly where Al2O3-based materials and Corundum Mullite are involved.