Introduction to Advanced Ceramics Tape Casting Process

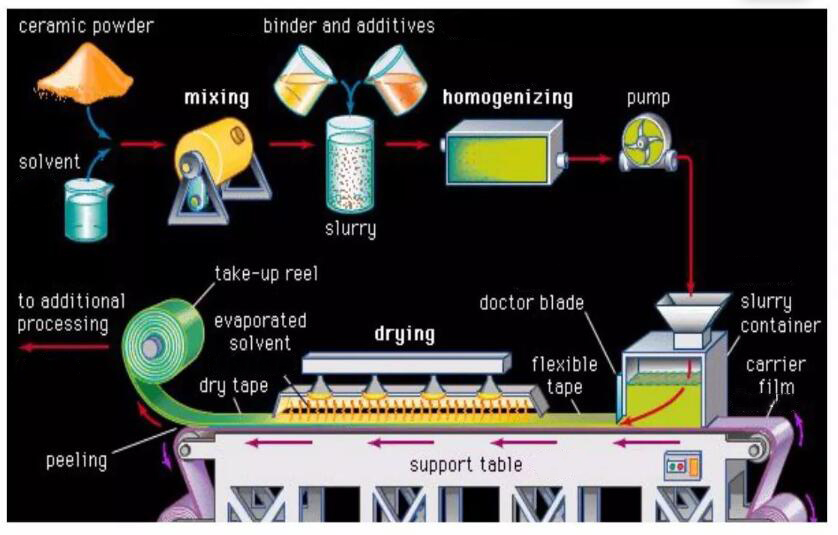

Tape casting, also known as doctor blade casting, is a fundamental ceramic shaping process. Its basic principle involves the flow of ceramic slurry with suitable viscosity and good dispersibility from the slurry trough of a tape caster to the substrate. This is achieved by the relative motion between the substrate and the doctor blade, which spreads the slurry. Under the influence of surface tension, a smooth upper surface is formed, and the thickness of the green tape is primarily controlled by the gap between the doctor blade and the substrate. The green tape enters a drying chamber, where solvent evaporates, and organic binders create a network structure between ceramic particles, resulting in green tapes with certain strength and flexibility. These dried green tapes are then peeled off from the substrate and rolled up for further processing. They can be cut, punched, or shaped as needed and are ultimately sintered to produce the final product.

Tape casting processes can be categorized into non-aqueous tape casting, aqueous tape casting, and gel-casting, among others.

The ceramic tape casting process includes various steps such as slurry preparation, tape casting, drying, debinding, and sintering, with slurry preparation and tape casting being the most critical aspects. The forming process is illustrated in the diagram below.

Advantages: Tape casting can produce ceramic tapes with smooth surfaces ranging from a few micrometers to 1000μm in thickness. The equipment is simple, the process is stable, it can be operated continuously, and it is suitable for automation, resulting in high production efficiency and consistent product performance. Therefore, it is the most important and effective process for preparing single-layer or multi-layer thin ceramic materials today.

Advantages: Tape casting can produce ceramic tapes with smooth surfaces ranging from a few micrometers to 1000μm in thickness. The equipment is simple, the process is stable, it can be operated continuously, and it is suitable for automation, resulting in high production efficiency and consistent product performance. Therefore, it is the most important and effective process for preparing single-layer or multi-layer thin ceramic materials today.

Disadvantages: The high binder content can lead to a shrinkage rate of up to 20% to 21%.

Applications: Ceramic capacitors, thick-film and thin-film circuit Al2O3 substrates, piezoelectric ceramic films, structural ceramic tapes, capacitors, thermistors, ferrites, piezoelectric ceramic blanks, mixed integrated circuit substrates, and more.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.