What Do You Know About Metal Ceramic Heater (MCH)?

A metal ceramic heater (MCH) is a compact, high-efficiency heating element that embeds a resistive circuit inside a ceramic body—most commonly alumina (Al₂O₃) or silicon nitride (Si₃N₄). By co-sintering the resistance element with the ceramic substrate, the heater becomes a sealed, electrically insulated, and mechanically robust unit with rapid heating, high watt density, and long service life. These characteristics make MCH an ideal choice for automotive systems, electronic tools, petroleum & gas equipment, and household appliances.

resistance element with the ceramic substrate, the heater becomes a sealed, electrically insulated, and mechanically robust unit with rapid heating, high watt density, and long service life. These characteristics make MCH an ideal choice for automotive systems, electronic tools, petroleum & gas equipment, and household appliances.

What Exactly Is a Metal Ceramic Heater?

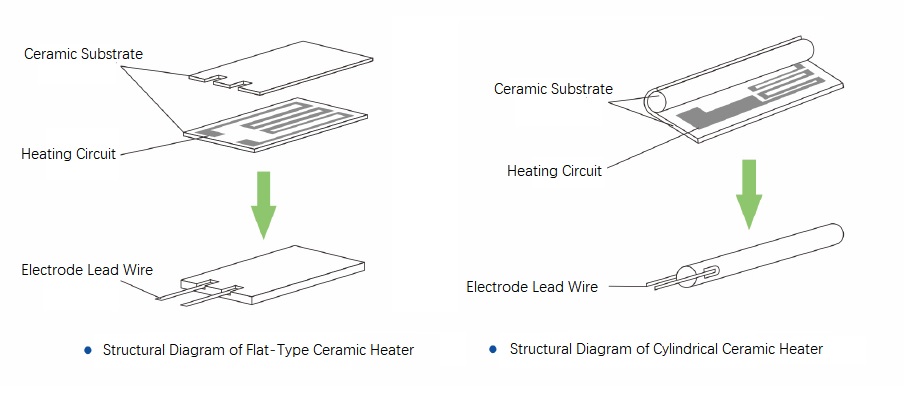

In an MCH, the resistive material (a printed thick-film resistance paste, a resistance sheet, or a wire) is placed within the ceramic “green body” and co-sintered into a monolithic structure. The ceramic matrix isolates the resistive circuit from ambient air, preventing oxidation and ensuring excellent dielectric strength and safety during operation. Typical form factors include plate, cylindrical, and tubular heaters to accommodate diverse assemblies.

How an MCH Is Built?

Alumina MCH — Thick-Film Printed Circuits

•A tungsten-based thick-film paste is screen-printed onto alumina tape-cast green sheets.

•After lamination and debinding, the stack is co-sintered at around 1600 °C, forming a thick-film heating circuit tightly bonded to the ceramic.

•The paste comprises: functional phase (tungsten particles for conduction), organic vehicle (forms a stable suspension and sets viscosity), and inorganic binder (anchors tungsten into a continuous conductive path after sintering).

Silicon Nitride MCH — Embedded Wire or Co-Pressed Powders

•Traditional: embed tungsten wire or print a high-temperature-capable resistance paste into the Si₃N₄ green body and sinter.

•Flat-type (integrated): blend a resistive powder with Si₃N₄ powder, press to shape, and gas-pressure sinter at about 1750 °C under nitrogen to obtain a one-piece heating element with exceptional thermal-shock resistance and durability.

Why Choose an MCH?

•Rapid heating & high watt density: small heater volumes reach setpoints quickly and deliver strong heat fluxes.

•Excellent insulation & safety:the ceramic body provides high dielectric strength and shields the circuit from oxidation.

•Longevity:sealed construction resists corrosion and reduces wire breakage/aging common in open-air coils.

•Clean & quiet:no sparks, no combustion, no noise—suitable for sensitive environments and even vacuum use.

Applications

Automotive

•Diesel glow elements / pre-heaters for cold starts (fast warm-up, robust at high temperature).

•O₂ sensor heaters based on alumina, enabling rapid sensor activation to reduce emissions right after engine start.

•Auxiliary cabin heaters or fuel vaporization elements using silicon nitride for faster warm-up and cleaner exhaust.

Electronic Tools

•Soldering irons & soldering stations: multi-circuit MCH allows output switching and integrated temperature sensing for precise control and fast recovery—common in pro-grade tools.

Petroleum & Gas Equipment

•Ignition heaters for kerosene/gas appliances deliver broad, stable hot zones without high-voltage spark noise.

•Vaporization heaters in fuel systems leverage MCH’s compactness and rapid heating to miniaturize assemblies and cut warm-up time.

Household Appliances

•Hair styling (curlers/straighteners): rapid rise, uniform profile, stable setpoint.

•Heated toilet seats & smart bidets: instant hot-water heating with high insulation and safety margins.

How to Specify an MCH?

1) Pick the Right Ceramic: Alumina vs. Silicon Nitride

•Alumina (Al₂O₃): cost-effective, proven thick-film process, good insulation, widely used in tools and appliances.

Typical thermal data in tool-class heaters: 21 W/(m·K) conductivity, 7.8×10⁻⁶/K CTE—helpful numbers for thermal-mechanical matching.

•Silicon nitride (Si₃N₄): superior thermal-shock and mechanical strength, excellent for harsh thermal cycling (automotive, combustion). Integrated powder-mix designs create a one-piece hot zone with minimal interfaces.

2) Electrical Sizing (Voltage, Resistance, Power)

Use the basics: P = V²/R, I = V/R, q″ = P/A (heat flux).

•Example (from a common spec): an MCH L60×Ø3.8 rated 110 VAC with R ≈ 220 Ω (±10%) yields P ≈ 110²/220 ≈ 55 W, heating length ≈ 25 mm—appropriate for compact soldering heaters.

3) Circuit Layout for Uniformity & Life

•Prefer serpentine traces with rounded corners to avoid current crowding.

•Keep uniform line width/spacing; avoid narrow “necks” that create hotspots.

•For multi-zone control, design independent circuits (front/rear or inner/outer coils) for tunable temperature maps. (Multi-circuit & output switching are standard capabilities in tool-class MCH.)

4) Temperature Sensing & Feedback

•Many tool-format heaters integrate a feedback resistor or sensor circuit (e.g., feedback resistance ~ 46–55 Ω appears in stock specs) to enable closed-loop control without external probes—ideal for compact irons.

•MCH is not self-limiting (unlike PTC). Always pair it with closed-loop control (PID/SSR/triac) for accuracy and safety.

5) Mechanical Integration & Interfaces

•Ensure flat, clean contact with the heated mass; use a thin, thermally conductive interface where needed to reduce contact resistance.

•Avoid over-constraining ceramics; allow a small degree of compliance or use spring features to limit assembly stress during heat-up (CTE mismatch).

•Lead exits: nickel leads, plated tabs, or gold-plated contacts (common options in catalogs) should match your connector and assembly process.

6) Environment & Safety

•For vacuum or fuel-exposed zones, the sealed ceramic body prevents oxidation and supports clean operation. (Vacuum suitability is highlighted in tool-class brochures.)

•Follow basic protections: over-temperature cut-off, fuse/thermal fuse, ground/insulation checks during certification.

MCH vs. Other Heater Types

Feature | MCH (Alumina/Si₃N₄) | PTC Ceramic | Open Coil / Cartridge |

Control behavior | Needs closed-loop control | Self-limiting near Curie temp | Needs control, more inertia |

Warm-up | Very fast | Fast | Varies (coil fast / cartridge moderate) |

Safety & insulation | Excellent (sealed, dielectric) | Good (self-limiting) | Coil exposed, cartridge insulated |

Environment | air / Vacuum / clean / fuel | Mostly ambient air | Ambient / contact heating |

Uniformity | High with proper layout | Moderate | Good (cartridge), coil varies |

Typical use | Automotive, tools, gas equipment, appliances | Heaters, defoggers, space heating | Mold/hot runner, blocks, oven |

Metal ceramic heaters combine ceramic insulation with embedded resistive elements to deliver fast, clean, and reliable heating in compact packages. By matching the ceramic (alumina vs. silicon nitride), sizing the resistance for your voltage/power, and implementing solid feedback control, you can achieve stable temperature, long life, and excellent safety in demanding environments—from automotive systems to precision electronic tools and clean home appliances.

Mascera provides custom alumina and silicon nitride MCH designs, including multi-zone circuits, integrated sensing, and application-specific mounting and terminations. Tell us your target temperature, voltage, power, geometry, and environment, and we’ll engineer the right heater for your build.