Ceramic Materials in Military Applications

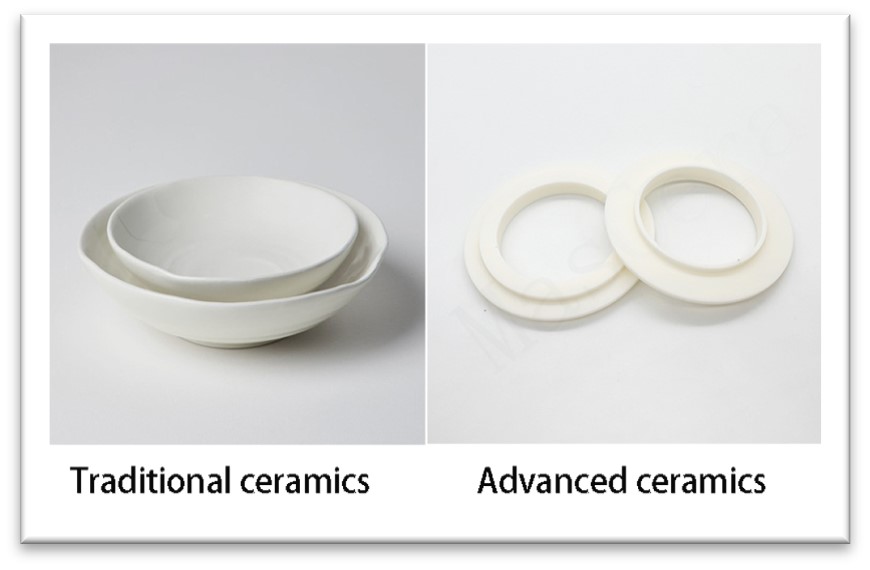

Broadly speaking, ceramic materials refer to all materials other than organic and metallic materials, namely, inorganic non-metallic materials. There are various types of ceramic products, with their chemical compositions, mineral compositions, physical properties, and manufacturing methods often closely intertwined without clear boundaries, yet with significant differences in applications. Hence, it is difficult to rigidly classify them into several systems, and detailed classification methods vary. As of now, there is no unified classification method internationally. According to the preparation techniques and application fields of ceramics, they can be divided into traditional ceramic materials and advanced ceramic materials.

Traditional ceramics:Traditionally, ceramics refer to various products made from clay and natural minerals through processes such as crushing, mixing, molding, and firing. They are commonly referred to as "common ceramics" or traditional ceramics, such as daily ceramics and architectural sanitary ceramics.

Advanced ceramics: According to chemical composition, they can be divided into oxide ceramics, nitride ceramics, carbide ceramics, boride ceramics, silicide ceramics, fluoride ceramics, sulfide ceramics, etc. According to properties and uses, they can be classified into functional ceramics and structural ceramics. Functional ceramics are mainly based on the special functions of materials, including electrical, magnetic, biological, thermal, and optical properties, such as insulating and dielectric ceramics, ferroelectric ceramics, piezoelectric ceramics, semiconductors, and sensitive ceramics; structural ceramics are mainly based on the mechanical and structural uses of materials, featuring high strength, high hardness, high temperature resistance, corrosion resistance, and oxidation resistance.

Functional ceramics account for approximately 70% of the market share in advanced ceramics, with the rest being structural ceramics. Military applications of ceramic materials mainly focus on structural materials and electronic devices:

1、Used in aircraft engines

Ceramic matrix composites are used in the hot section components of aircraft engines due to their high-temperature resistance. Studies have shown that ceramic matrix composites can increase the turbine inlet gas temperature by over 300K. Additionally, ceramic matrix composites have a low density, which contributes to engine weight reduction. With the continuous pursuit of fuel efficiency in the civil aviation industry, GE Aviation expects the application of ceramic matrix composites in aviation to grow tenfold in the next decade.

2、Used in aircraft brake discs

Compared to silicon carbide brake discs, carbon-ceramic brake discs exhibit a 1-2 times increase in static friction coefficient, over 60% reduction in degradation of wet friction performance, more than 50% decrease in wear rate, and a doubling to twofold increase in lifespan. Production cycle is reduced by two-thirds, production costs are lowered by one-third, energy consumption is decreased by two-thirds, and cost-effectiveness is improved by two to three times. It is currently the only material discovered internationally that maintains its physical properties without deterioration under high-temperature environments up to 1500℃. Upon widespread adoption, it could save approximately 300 million RMB in annual costs for Chinese civil aviation aircraft.

3、Used in rocket engine thermal structural components

Ceramic matrix composites can be used in rocket engines due to their high resistance to thermal shock, high chemical stability with liquid propellants, high-temperature resistance compared to metal materials, and high creep resistance, making them ideal materials for thermal structural components of liquid rocket engines.

4、Used in thermal protection of spacecraft and missiles

During re-entry into the atmosphere, spacecraft experience intense aerodynamic heating, with temperatures on the nose cone and leading edges of wings reaching up to 1650°C. Thermal protection systems are crucial for spacecraft. The development of C/SiC composite materials allows for the integration of structural and heat dissipation functions, especially after the Columbia disaster, garnering more attention for C/SiC ceramic matrix composites. Components in thermal structural materials include nose cones, canards, wings, and covers of spacecraft and missiles.

5、Used in satellite reflectors

The requirements for satellite reflector materials include low density, high specific stiffness, low coefficient of thermal expansion (CTE) at low temperatures, high thermal conductivity, adequate strength and hardness, and design flexibility. Glass and metal reflectors have limitations in processing large lightweight reflectors. Therefore, C/SiC composite material reflectors are being researched internationally. These composite materials have low density, high stiffness, low CTE at low temperatures, good thermal conductivity, ideal thermal and mechanical properties, and can be excellently polished, making them ideal materials for satellite reflector bases.

6、Used in physical bulletproofing

Silicon carbide can be used in protective layers such as bulletproof vests, combat aircraft, and armored vehicles. Bulletproof vests consist mainly of a cover and a protective layer, which can absorb the kinetic energy of bullets or fragments, providing significant protection against low-speed bullets or fragments and reducing damage to the chest and abdomen within certain indentation limits. Silicon carbide ceramic matrix composites can be used to manufacture sturdy armor plates resistant to impacts.

7、Used in aircraft armor

Some military helicopters are equipped with ceramic armor systems, including ceramic armored seats, components, and panel systems. Additionally, ceramic matrix composites are used in armored vehicles of the army, such as the Stryker medium armored vehicle.

8、Used in informationized electronic devices

There is a strong demand for military ceramic capacitors. Besides being widely used in civilian fields, with the acceleration of the informationization of weapons and equipment, electronic ceramics such as ceramic capacitors in the military field are continuously increasing in demand, especially chip multilayer ceramic capacitors.

Ceramic materials play an important role in the modern military industry due to their unique properties such as high temperature resistance, high strength, lightweight, electrical and thermal insulation properties, etc. With the advancement of technology and the development of new material technologies, the application scope of ceramic materials is expected to further expand, providing critical solutions to many challenges facing the world today.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.