Quality Assurance

Quality Guaranteed — From Prototypes to Mass Production

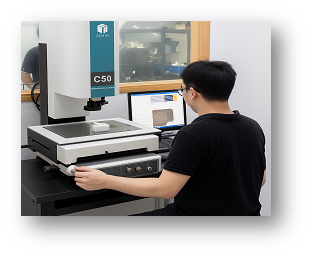

At Mascera, quality management is integrated into every step of our ceramic component manufacturing process. We implement strict quality control procedures, using high-precision instruments to ensure each component meets all technical and dimensional requirements before it reaches our customers.

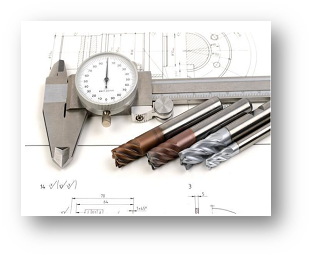

In-House Inspection Capabilities Our inspection team is equipped with advanced measuring systems to verify every critical parameter with high accuracy. Main Inspection Equipment: ◆ Micrometer ◆ 2D measuring instruments ◆ Density tester ◆ Optical profilometer ◆ Surface roughness testers ◆ Industrial microscopes ◆ Coordinate measuring machine (CMM) ◆ Roundness Tester |

|

Quality Control Throughout the Process We conduct inspections at all key production stages: ◆ Incoming Material Inspection ◆ In-Process Checks ◆ Post-Sintering Inspection ◆ Final Inspection ◆ Customized Test Reports |

|

Certifications & Standards ◆ ISO 9001:2015 Quality Management System certified ◆ Inspection procedures follow customer specifications ◆ Traceable inspection records for all critical dimensions |

|

Our Commitment to Quality

Mascera is committed to delivering defect-free ceramic components that meet the highest standards of precision and reliability. Our quality culture ensures long-term performance in every part we ship.