Application of Advanced Ceramics in Solar Thermal Power Systems

Solar thermal power generation is a clean energy technology that uses collectors to convert solar radiation into thermal energy, which is then used to generate electricity through a thermodynamic cycle. Existing solar power systems worldwide can be broadly classified into three categories based on the operating temperature: parabolic trough systems, tower systems, and dish systems. Some advanced ceramic materials can be applied to the receivers of tower solar thermal power systems.

1、Operating Principles of Parabolic Trough, Dish, and Tower Solar Thermal Power Systems

Parabolic Trough Solar Thermal Power System

This system uses parabolic trough mirrors to focus sunlight onto a receiver tube, heating the working fluid. The heated fluid generates steam through a heat exchanger, which then drives a steam turbine connected to a generator, producing electricity.

Dish System

Also known as a parabolic dish system, it utilizes a parabolic dish-shaped mirror to concentrate sunlight onto a receiver at the focal point. Structurally, it resembles a large parabolic radar antenna. Due to the point focus of the parabolic dish, the concentration ratio can reach several hundred to several thousand, enabling extremely high temperatures. Multiple dish systems can be connected in parallel to form a small solar power plant to meet electricity demands.

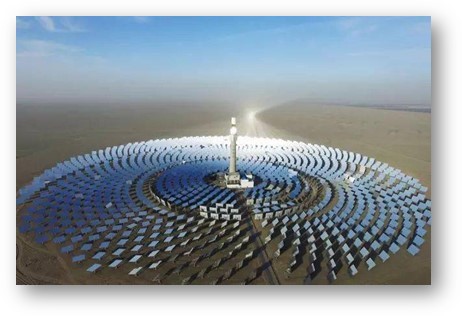

Tower System

Also known as a central receiver system, it uses an array of large mirrors (heliostats) installed on the ground. Each heliostat tracks the sun on two axes, accurately reflecting and concentrating sunlight onto a receiver at the top of a central tower. The concentrated solar energy heats the working fluid in the receiver, generating superheated steam, which then enters the power subsystem to complete the thermal energy conversion process.

2、Ceramic Materials Applicable in Solar Power Systems

The tower solar thermal power system is highly regarded for its high concentration ratio (200-1000 kW/m²), high thermodynamic cycle temperature, low heat loss, simple system structure, and high efficiency. The receiver, being the core component of the tower solar thermal power system, needs to withstand radiation intensities 200-300 times that of natural sunlight, with operating temperatures exceeding 1000°C. Therefore, its performance is crucial for the stable operation and efficiency of the power generation system. Traditional metal receivers have temperature limitations, making ceramic receiver materials a new research focus.

Due to the uneven and unstable solar flux density, the following requirements are imposed on ceramic receiver materials:

(1)High-temperature oxidation resistance

The material should not undergo oxidative damage in long-term high-temperature working environments.

(2)Good high-temperature mechanical properties and thermal shock resistance

To prevent material damage from thermal hotspots.

(3)High solar radiation absorption rate

To ensure the material can fully absorb solar energy.

(4)Three-dimensional or two-dimensional connected structure

Ensuring high permeability, low airflow resistance, and uniform, stable airflow distribution.

(5)High specific surface area

Providing a large heat exchange area to ensure sufficient heat exchange with the air.

The following ceramic materials can be used as receiver materials:

These can withstand temperatures above 1000°C, have high mechanical strength and chemical stability, and are resistant to acids and alkalis, with good thermal conductivity, insulation strength, resistivity, and wear resistance. However, their drawbacks include low thermal conductivity and solar radiation absorption rate, necessitating a surface coating to increase solar radiation absorption. During high-temperature use, the substrate and coating can crack, and poor shock resistance limits practical application.

(2)Cordierite Ceramics

These have low thermal expansion coefficients, good thermal shock resistance, and large specific surface areas. However, due to low strength, materials such as mullite and zirconia are often added to improve strength. Like alumina ceramics, cordierite ceramics are suitable only for medium-temperature applications.

These exhibit high strength, large specific surface area, corrosion resistance, oxidation resistance, good thermal insulation, thermal shock resistance, and high-temperature resistance. Compared to alumina and cordierite ceramics, silicon carbide ceramics have better high-temperature performance. Research indicates that sintered silicon carbide receivers can achieve air outlet temperatures up to 1200°C without material damage.

Advanced ceramics have yet to be widely deployed in the solar market due to technical costs. However, with technological advancements, product updates, and improved production efficiency, ceramic products that effectively and efficiently match solar thermal power systems will be widely introduced to the market.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.