Main Processes of Alumina Ceramic Products

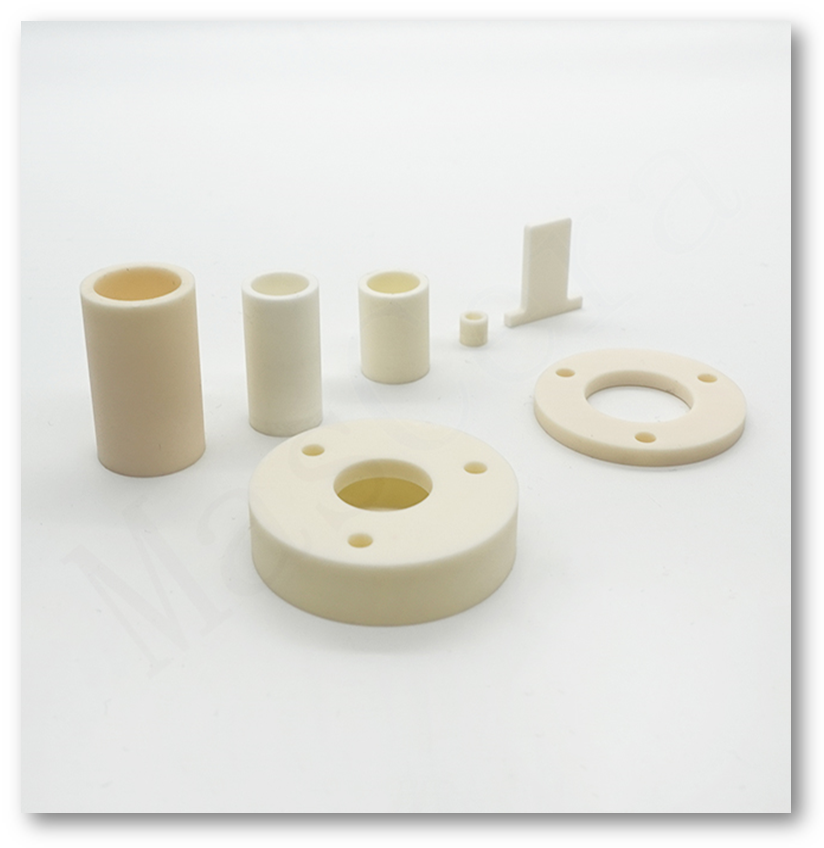

Alumina ceramic products are widely used in electronic, thermal, mechanical, and high-temperature applications due to their excellent electrical insulation, mechanical strength, wear resistance, and thermal stability.However, the performance and reliability of alumina ceramic components are not determined by material purity alone. The manufacturing process plays a decisive role in defining final properties, dimensional stability, and long-term service performance.

mechanical strength, wear resistance, and thermal stability.However, the performance and reliability of alumina ceramic components are not determined by material purity alone. The manufacturing process plays a decisive role in defining final properties, dimensional stability, and long-term service performance.

This article focuses on the main manufacturing processes of alumina ceramic products, explaining how different forming, sintering, and machining technologies are selected based on product geometry, size, tolerance requirements, and application conditions.

For a general introduction to alumina ceramic materials, properties, and applications, please refer to our parent guide:Everything You Need to Know About Alumina Ceramic.

Overview of Alumina Ceramic Manufacturing Flow

The manufacturing of alumina ceramic products typically consists of three key stages:

▪ Forming– shaping alumina powder into a green body

▪ Sintering– densifying the green body at high temperature

▪ Machining and finishing– achieving final dimensions and surface quality

Among these stages, forming is the foundation of the entire process. The selected forming method determines feasible geometries, internal uniformity, achievable tolerances, and manufacturing cost. Sintering and machining then refine material properties and dimensional accuracy.

Forming Processes of Alumina Ceramics

Alumina ceramics can be formed using different shaping technologies depending on part geometry, size, wall thickness, dimensional tolerance, and application requirements.In practical manufacturing, the selection of a forming process is a balance between design feasibility, performance requirements, production volume, and cost efficiency.

The following sections introduce the main forming processes used for alumina ceramic products and the types of components they are best suited for.

1.Dry Pressing

Dry pressing is one of the most commonly used forming processes for alumina ceramic components with relatively simple geometries. Granulated alumina powder is compacted in a rigid metal die under high pressure to produce near-net-shape parts.

Typical Dry Pressing Products

▪ Ceramic washers and spacers

▪Flat plates and discs

▪Simple electronic insulation components

▪Structural parts with uniform thickness

When Dry Pressing Is Selected

▪High-volume production

▪Simple shapes with limited height variation

▪Good thickness consistency

▪Cost-sensitive applications

2.Cold Isostatic Pressing (CIP)

Cold isostatic pressing (CIP) applies uniform pressure in all directions using a flexible mold, resulting in higher green density and better internal uniformity compared to uniaxial pressing.

Typical CIP Products

▪Alumina ceramic rods

▪Thick-walled tubes

▪Large or solid structural components

When CIP Is Selected

▪Thicker cross-sections

▪Higher mechanical strength requirements

▪Reduced risk of internal defects

3.Extrusion

Extrusion is used to produce alumina ceramic components with a constant cross-section by forcing plasticized ceramic material through a shaped die. This process is particularly suitable for long or continuous parts.

Typical Extrusion Products

▪Alumina ceramic tubes

▪Long ceramic rods

▪Multi-hole tubes

▪Continuous insulation tubes

When Extrusion Is Selected

▪Long-length parts

▪Hollow or multi-channel geometries

▪Stable cross-sectional profiles

4.Ceramic Injection Molding (CIM)

Ceramic injection molding (CIM) combines fine alumina powder with organic binders and injects the mixture into precision molds, enabling the production of complex-shaped ceramic components with high repeatability.

Typical CIM Products

▪Small, complex-shaped alumina ceramic parts

▪Precision electronic ceramic components

▪Thin-walled structural parts

When CIM Is Selected

▪Complex geometries that are difficult to machine

▪Tight dimensional tolerances after sintering

▪Medium to high production volumes

5.Slip Casting

Slip casting are forming processes based on liquid ceramic slurries. These methods are especially suitable for large, long, or thick-walled alumina ceramic components, where rigid tooling is impractical.

Typical Slip Casting Products

▪High-temperature protection tubes

▪Furnace tubes

▪Thermocouple protection tubes

▪Long alumina ceramic tubes with thick walls

When Slip Casting Is Selected

▪Large dimensions or extended lengths

▪Thick wall structures

▪High-temperature operating environments

▪Low to medium production volumes

6.Tape Casting

Tape casting is a forming process used to manufacture thin, flat alumina ceramic sheets by casting a ceramic slurry onto a moving carrier surface, followed by controlled drying.

Typical Tape Casting Products

▪Alumina ceramic substrates

▪Thin ceramic wafers

▪Flat electronic insulation sheets

When Tape Casting Is Selected

▪Thin and flat components

▪Tight thickness tolerance requirements

▪Electronic and power device applications

Forming Process Selection Overview

| Forming Process | Tooling Cost | Typical Products | Manufacturing Cost |

| Dry Pressing | Medium | Washers, plates, simple insulators | Low |

| CIP | Low | Rods, thick tubes, solid parts | Medium |

| Extrusion | Medium | Tubes, rods, multi-hole tubes | Medium |

| CIM | High | Small, complex-shaped parts | Medium to High |

Slip Casting | Low | High-temperature protection tubes, long tubes | Medium |

| Tape Casting | Medium | Substrates, ceramic wafers | Low to Medium |

It should be noted that production volume suitability is closely related to tooling requirements. Processes requiring rigid tooling are generally more economical for medium to high-volume production, while flexible forming methods such as extrusion, slip casting, and tape casting offer greater scalability from small to large batches.

The selection of sintering temperature and process parameters is closely related to the intrinsic properties of aluminum oxide (Al₂O₃), including density, grain structure, and dielectric performance.

Sintering Process of Alumina Ceramics

Sintering is a critical step in the manufacturing of alumina ceramic products. During this process, the formed green bodies are heated to high temperatures, allowing alumina particles to bond together through solid-state diffusion and form a dense ceramic structure.

Through proper sintering, alumina ceramic components achieve:

▪High density and low porosity

▪Improved mechanical strength

▪Stable thermal and electrical properties

Key Factors in Alumina Ceramic Sintering

1.Sintering Temperature

Selected based on alumina purity, particle size, and product geometry. Higher-purity alumina typically requires higher sintering temperatures.

2.Holding Time

Adequate soaking time ensures uniform densification. Insufficient time may leave residual porosity, while excessive time can cause abnormal grain growth.

3.Heating and Cooling Rates

Controlled temperature ramps are essential to minimize thermal stress, warpage, or cracking—especially for long tubes and thick-walled parts.

4.Atmosphere Control

Most alumina ceramics are sintered in air. Certain electronic applications may require controlled atmospheres to ensure stable electrical performance.

Sintering quality directly affects density, grain structure, dimensional stability, and long-term reliability, making it as important as material purity itself.

In addition to processing parameters, the selected alumina ceramic grade significantly influences sintering behavior and final properties. Higher-purity alumina grades generally require higher sintering temperatures and achieve higher density and better grain growth uniformity, which in turn leads to improved final performance in thermal, mechanical, and electrical applications.

Common Machining Operations

Grinding– achieving precise outer diameters, flatness, and parallelism

Lapping and Polishing– improving surface finish and flatness

Dilling and Slotting– creating holes or functional features with minimal chipping

Machining Strategy and Cost Considerations

Machining alumina ceramics is significantly more time-consuming and costly than machining metals. Therefore, manufacturing strategies typically aim to:

▪Maximize forming accuracy

▪Minimize post-sintering material removal

▪Balance tolerance requirements with cost efficiency

Design choices such as uniform wall thickness, reasonable tolerances, and avoidance of sharp internal corners help improve machinability and reduce overall manufacturing cost.

Manufacturing Process Integration

The final quality of alumina ceramic products is determined by the integration of forming, sintering, and machining processes, rather than any single step.

▪Formingdefines shape feasibility and internal uniformity

▪Sinteringestablishes material properties and dimensional stability

▪Machiningensures functional accuracy and surface quality

Optimizing these processes as a complete manufacturing chain enables alumina ceramic components to deliver consistent performance in demanding industrial, electronic, and high-temperature applications.

Alumina Ceramic Products To support practical design and manufacturing needs, Mascera offers a comprehensive range of alumina ceramic products, including standard shapes and custom-engineered components. Our product portfolio covers substrates, tubes, rods, plates, and wear parts designed for electronic, thermal, and mechanical applications.

🔗 Explore our alumina ceramic product range