Characteristics and Applications of Silicon Carbide Ceramics

Silicon carbide ceramics possess various advantageous properties, including chemical stability, high temperature resistance, wear resistance, corrosion resistance, high thermal conductivity, low thermal expansion coefficient, and high hardness. These qualities make it an ideal material for numerous industries.

Characteristics:

As a high-performance structural ceramic material, silicon carbide ceramics exhibit exceptional comprehensive properties that cannot be matched by traditional metallic materials due to their crystal structure and highly covalent Si-C bonds:

1. High strength at high temperatures with minimal creep, suitable for various high-temperature environments.

2. Low thermal expansion coefficient and high thermal conductivity, providing excellent resistance to thermal shocks.

3. High chemical stability and outstanding corrosion resistance.

4. High hardness and low friction coefficient, ensuring excellent wear resistance.

5. Low density and high elastic modulus.

6. Electrical properties can be tuned through doping, enabling transitions from insulation to semiconduction and conduction.

7. Demonstrates excellent chemical stability and high-temperature phase stability, displaying resistance to corrosion.

Applications:

Silicon carbide ceramic materials, with their remarkable wear resistance, thermal conductivity, oxidation resistance, and high-temperature mechanical properties, find widespread applications in fields such as energy and environmental protection, chemical machinery, semiconductor technology, and defense industries.

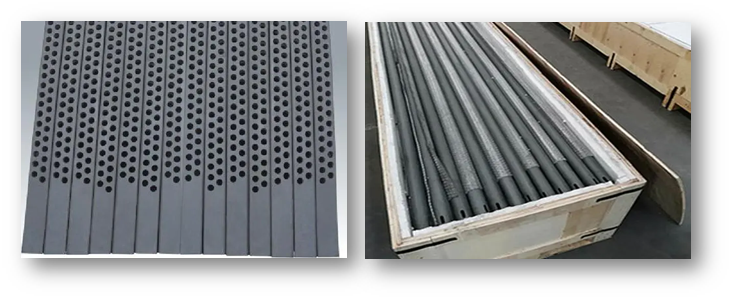

1. High-Temperature Applications:

Silicon carbide ceramics are used for high-temperature furnace components, including beams, cooling tubes, and rods. Due to their exceptional high-temperature strength, resistance to creep, and thermal shock resistance, they are vital materials for static hot sections of rockets, airplanes, car engines, and gas turbines.

Silicon carbide ceramic beams & rods

2. Heating and Heat Exchange Industries:

The excellent high-temperature performance and high thermal conductivity of silicon carbide ceramics make them suitable for heat exchange systems in industries like steel and metallurgy. Applications include burners, heat exchangers, radiators, and thermal protection sleeves.

Silicon carbide ceramic burners & heat exchangers

3. Corrosion-Resistant Environments:

With exceptional chemical and physical stability, silicon carbide ceramics are suitable for producing desulfurization nozzles. They are also used extensively in components of magnetic and shielded pumps in the chemical industry.

Silicon carbide ceramic shielded pumps

4. Wear-Resistant Mechanical Applications:

Silicon carbide's high hardness and low friction coefficient provide outstanding wear resistance, making it ideal for sliding friction and wear conditions. It is used to create high-precision, high-purity sealing rings with excellent surface finish and dimensional accuracy for mechanical seals in demanding environments.

Silicon carbide ceramic seals

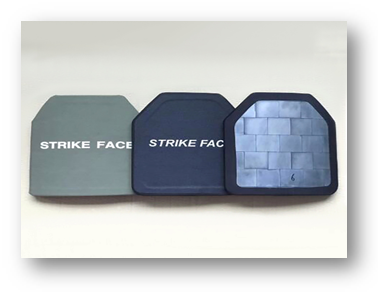

5. Defense and Military Applications:

Silicon carbide is considered one of the most promising high-performance ballistic armor materials. It can be used in bulletproof vests and armored vehicles. With a hardness second only to diamond and boron carbide, silicon carbide exhibits a Mohs hardness of 9, demonstrating high hardness and elastic modulus.

Silicon Carbide Ballistic Ceramic

6. Optical Applications:

Silicon carbide's lightweight nature, high stiffness, and low thermal expansion coefficient meet the physical, optical, and processing requirements of space mirrors in optical applications.

Satellite Reflective Mirror

7. Semiconductor Industry:

In the semiconductor field, silicon carbide is used for components such as grinding wheels, vacuum chucks, crucibles, and fixtures due to its high precision, high purity, chemical resistance, and ion corrosion resistance capabilities.

Silicon Carbide vacuum chucks

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.