Characteristics and performance of high purity alumina crucible

Alumina ceramic crucible (al2o3 ceramic crucible) is a common experimental vessel made of high-purity alumina powder and combined with modern molding and sintering processes. It is widely used in various laboratories, laboratories, metal or non-metal sample analysis and other various industrial analysis.

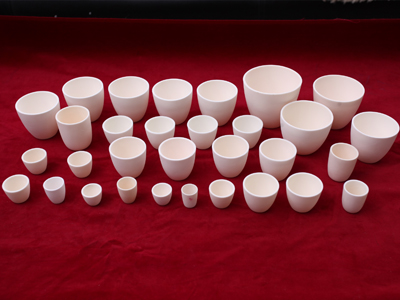

Different shapes and capacities of alumina ceramic crucibles can be produced according to the needs of use, such as: curved alumina crucible, square alumina crucible, alumina ceramic boat crucible (rectangular alumina ceramic crucible), straight (cylindrical) alumina crucible and various special-shaped alumina crucibles. The volume range can be produced is 5-1000ml.

Alumina ceramic crucibles have the following characteristics.

1. Low thermal conductivity: Alumina ceramic crucible is a poor conductor of heat, and heat transfer is slow. When it is used to hold boiling water or scalding solution, it will not be too hot to handle.

2. Good sealing: Alumina ceramics have high density, low porosity and water absorption. After storing the solution tightly, it can prevent the solution from volatilizing, infiltrating and contamination by external bacteria.

3. Stable chemical properties: The ceramic crucible has good acid and alkali corrosion resistance, so it is not easy to chemically react with these substances, and it will not rust or age.

4. High operating temperature: 1600°C for long-term use and 1800°C for short-term use. It is recommended that the heating rate should not exceed 50°C every 10 minutes, which will prolong the service life of the product.

5. Easy to clean: washed with water or 10% hydrochloric acid, and dried. It can be used repeatedly without affecting the experimental results.

From Material Knowledge to Product Selection

Understanding alumina ceramic properties is only the first step. For real-world applications, engineers often need to evaluate available alumina ceramic products in specific forms and grades. Mascera supplies a wide selection of alumina ceramic components suitable for electronics, thermal management, and structural applications.

🔗 View available alumina ceramic products