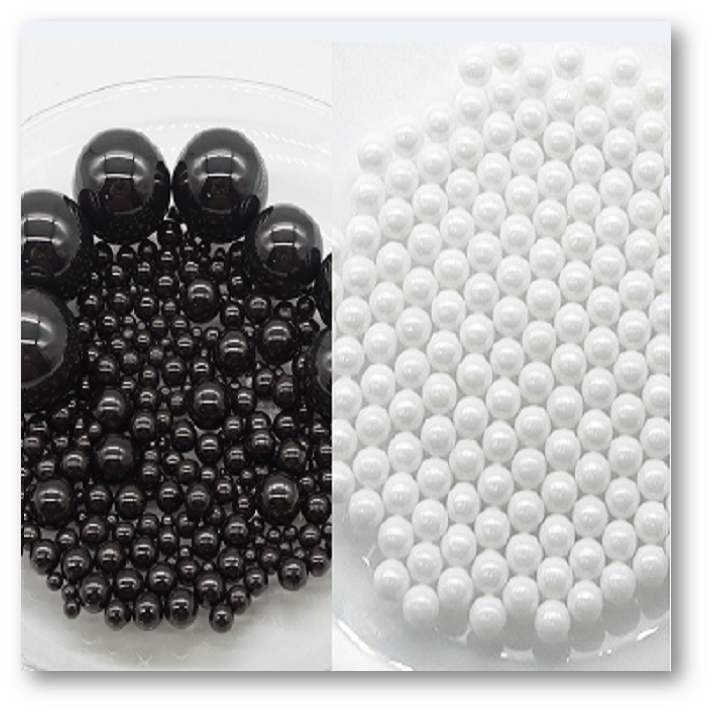

Which Is Better for Ceramic Bearing Balls: Zirconia or Silicon Nitride

When selecting materials for ceramic bearing balls, zirconia (ZrO2) and silicon nitride (Si3N4) are the two most common choices. Both materials offer excellent hardness, corrosion resistance, and high-temperature performance, but they differ significantly in several technical aspects. This article compares zirconia ceramic bearing balls and silicon nitride ceramic bearing balls in terms of density, hardness, thermal behavior, toughness, corrosion resistance, friction, and application scenarios. It also emphasizes the importance of hybrid ceramic bearings, where ceramic balls are paired with metal rings, as the dominant configuration in modern industry.

Density and Weight

Zirconia ceramic bearing balls are denser, with a density around 5.95 g/cm³, making them much heavier than silicon nitride ceramic bearing balls, which have a density around 3.2 g/cm³. The lighter weight of silicon nitride balls results in lower centrifugal forces during high-speed rotation, enabling better speed performance and reducing wear. This makes silicon nitride the preferred material in most high-speed hybrid ceramic bearings.

Hardness and Wear Resistance

Both zirconia and silicon nitride are significantly harder than steel, but silicon nitride has a higher hardness level. This provides superior wear resistance and durability, especially in applications with continuous high-speed contact. Zirconia also offers excellent wear resistance, though slightly inferior to silicon nitride in terms of surface retention over long-term use.

Toughness and Brittleness

Zirconia exhibits higher fracture toughness, making it more resistant to impact and mechanical shock. It can tolerate vibration or misalignment better than silicon nitride, which is inherently more brittle. This makes zirconia a better choice for applications involving intermittent loads or where mechanical stress is a concern.

Thermal Expansion and Temperature Resistance

Zirconia has a thermal expansion rate close to steel, which simplifies fit design in hybrid bearings. However, silicon nitride has a much lower thermal expansion coefficient and can maintain dimensional stability over wider temperature ranges. In terms of maximum operating temperature, silicon nitride outperforms zirconia, making it suitable for extreme high-temperature environments.

Corrosion Resistance

Both zirconia and silicon nitride offer excellent corrosion resistance. Zirconia performs well in alkaline environments, while silicon nitride is more stable in acidic conditions and does not suffer from low-temperature degradation in steam. Overall, silicon nitride provides slightly broader chemical stability.

environments, while silicon nitride is more stable in acidic conditions and does not suffer from low-temperature degradation in steam. Overall, silicon nitride provides slightly broader chemical stability.

Friction and Speed Capability

Silicon nitride has a lower coefficient of friction than zirconia, making it ideal for high-speed applications with minimal lubrication. Its light weight and smooth surface reduce rolling resistance and heat generation. Zirconia also performs well but is generally not recommended for ultra-high-speed systems.

Application Suitability

Zirconia ceramic bearing balls are suitable for applications requiring high toughness, thermal insulation, and corrosion resistance, such as chemical equipment, medical devices, and moderate-speed rotating systems. Silicon nitride ceramic bearing balls are widely used in high-speed spindles, aerospace engines, electric motors, and precision tools due to their lightweight, high hardness, and superior speed capabilities.

In practice, most industrial ceramic bearings are hybrid ceramic bearings, combining steel rings with ceramic balls. This configuration balances strength, cost, and performance. Silicon nitride is the most commonly used ball material in hybrid bearings. Full ceramic bearings, which use ceramic for both balls and rings, are used in niche environments like extreme corrosion, high vacuum, or electrical insulation applications but are less common due to brittleness and cost.

When comparing zirconia vs silicon nitride ceramic balls, the choice depends on the application's specific needs. Silicon nitride is generally preferred in hybrid ceramic bearings for its high-speed performance, low friction, and thermal stability. Zirconia is a viable alternative when greater toughness, better steel compatibility, or cost efficiency is required. Understanding these differences helps engineers and decision-makers select the right ceramic material for optimal bearing performance.