Boron Nitride Ceramic

-

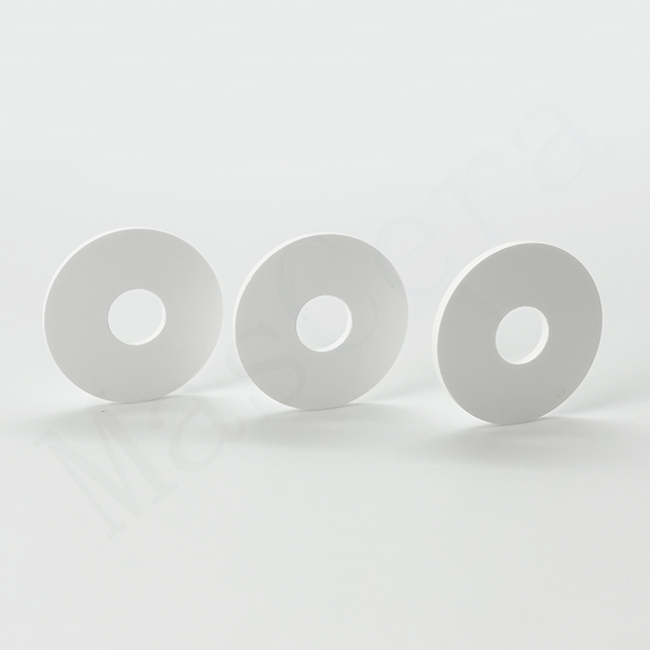

Pbn Pyrolytic Boron Nitride Ceramic Washer

Pyrolytic boron nitride is also called as PBN or Pyrolytic BN, it is an advanced ceramic material with excellent properties. It also has hexagonal crystal structure like hot pressed boron nitride ceramic, but is produced in different manufacturing process. PBN ceramic is produced by the method of chemical vapour deposition (CVD), no need to go through the traditional hot pressing sintering process, without adding any sintering agent, the purity is able to reach 99.99%.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Grade Zsbn Boron Nitride Ceramic Nozzle

ZSBN ceramic is one type of hot pressed boron nitride ceramic, it is a composite material that combines the excellent properties of hot pressed boron nitride and zirconia. ZSBN ceramic not only has the excellent thermal stability and non-wetting property of hot pressed boron nitride, but also has good wear resistance and high strength of zirconia. ZSBN ceramic has perfectly overcome the defect of pure boron nitride ceramic, making it able to be used for applications where good thermal shock resistance, non-wetting property and good wear resistance are needed. ZSBN ceramic is widely applied for molten metal applications such as continuous casting breakrings, metal powder atomizing nozzles, and nozzle for amorphous soft magnetic etc.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

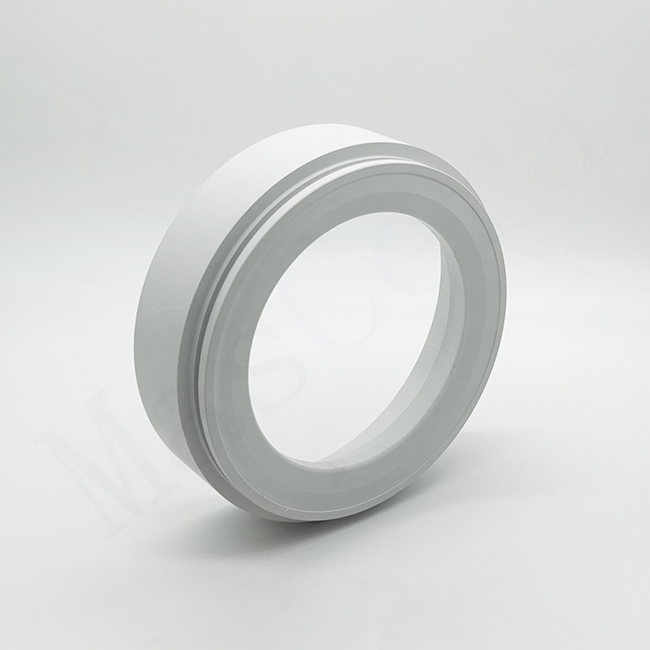

Boron Nitride Break Ring For Horizontal Continuous Casting

The Mascera BN-ZrO2 Break Ring is a high-performance component designed for horizontal continuous casting applications. It is constructed using a composite material comprising boron nitride (BN) and zirconia (ZrO2), ensuring exceptional reliability and longevity. This separation ring plays a critical role in maintaining a stable solidification front and enabling controlled withdrawal of the cast strand.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

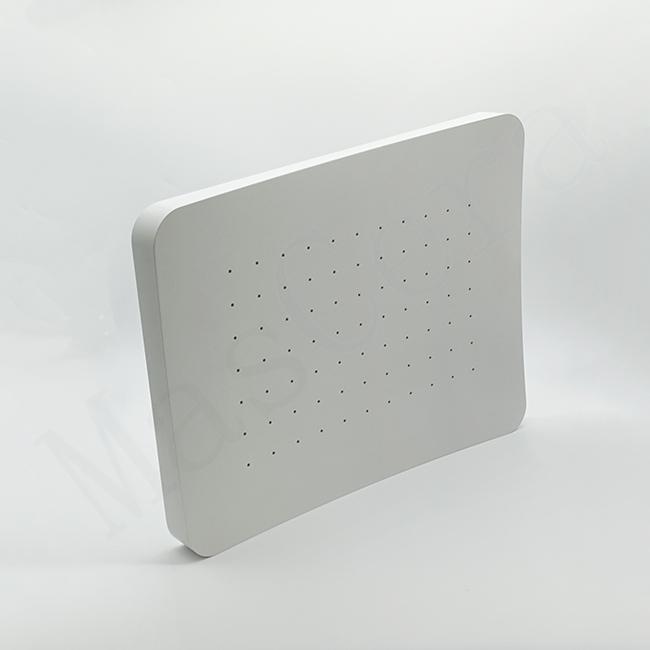

HBN boron nitride plate for precision glass molding

A hot-pressed hexagonal boron nitride (hBN) mold by Mascera, designed for precision glass production.With high temperature resistance, low adhesion, and stable dimensions, these molds outperform traditional graphite. Experience extended lifespan, improved efficiency, and enhanced mold stability. Upgrade your glass manufacturing process with our advanced hBN molds, minimizing defects and optimizing mold release.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Hot

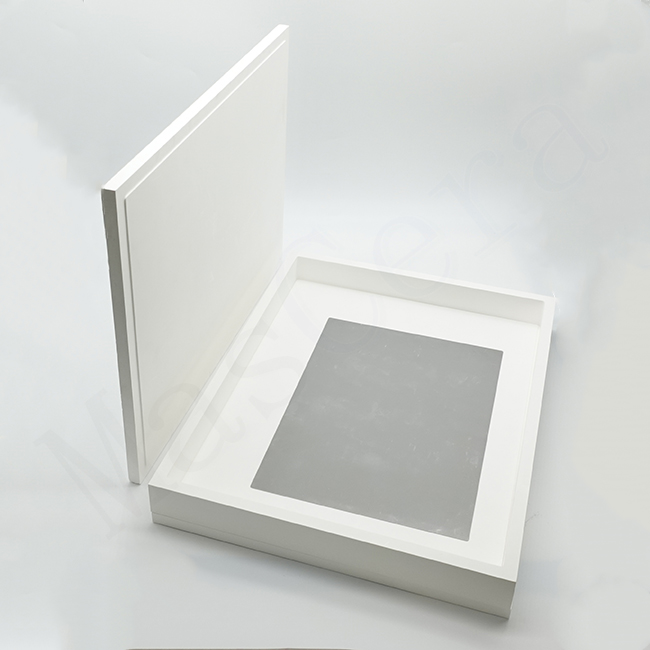

Boron nitride square crucible for sintering ceramic substrates

boron nitride (BN) crucible offers advantages of low wettability, chemical stability, high-temperature stability, and good thermal conductivity in the sintering of aluminum nitride (AlN) and silicon nitride (Si3N4) substrates. These advantages provide a reliable, clean, and high-quality sintering environment, ensuring the substrates are sintered in optimal conditions and maintain the desired performance.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Pbn Pyrolytic Boron Nitride Boat for semiconductor manufacturing

PBN boats are manufactured using the Chemical Vapor Deposition (CVD) process, featuring exceptional purity, outstanding thermal stability, and excellent electrical insulation. PBN boats characteristics make them ideal for semiconductor manufacturing, precision crystal growth, and other high-temperature processes.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Boron Nitride Composite Evaporation Boat for Vacuum Deposition Coating

The evaporation boat used in mascara production is made of a composite material of titanium diboride and boron nitride. Boron nitride composite evaporation boats are advanced evaporation vessels in the vacuum coating industry, known for their long lifespan, uniform evaporation, stable performance, and ease of use. They are widely used in industries such as packaging coating, color cathode ray tubes, and electronics, and have completely replaced older-generation products like graphite crucibles.

Any inquiry please email info@mascera-tec.com or call +86 13860446139Boron Nitride Composite Evaporation Boat boron nitride Evaporation Boat Evaporation Boat for Vacuum Deposition CoatingEmail Details