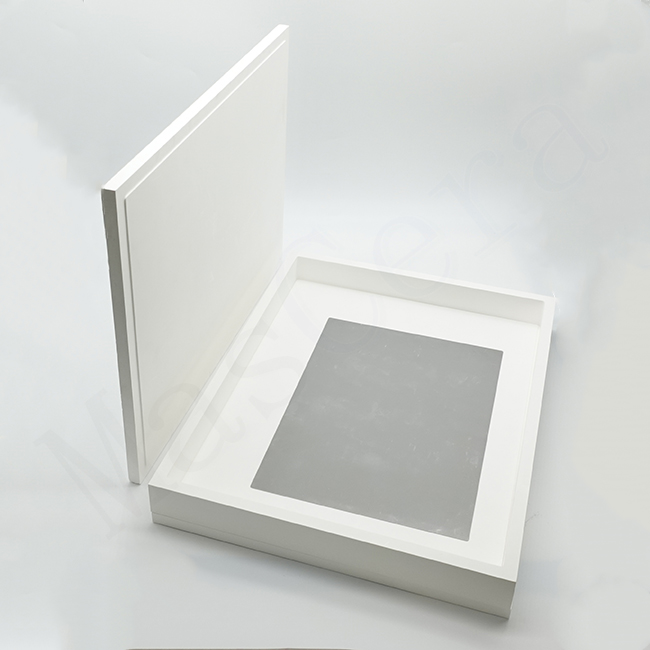

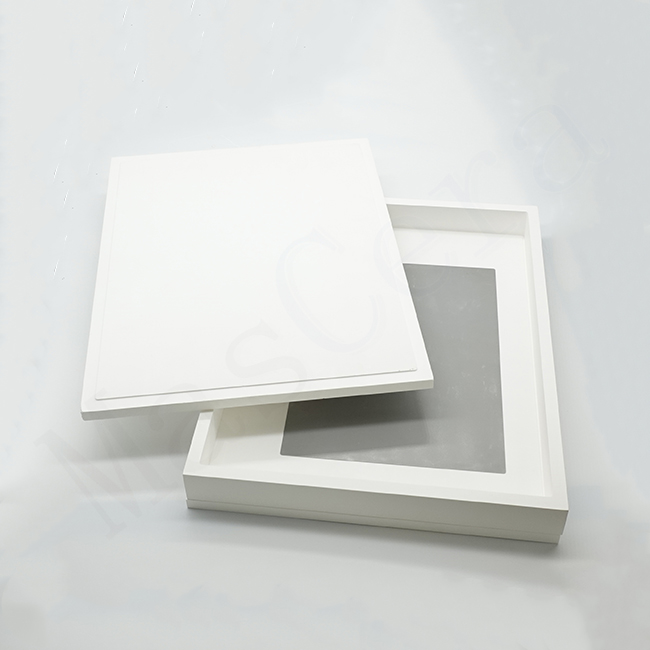

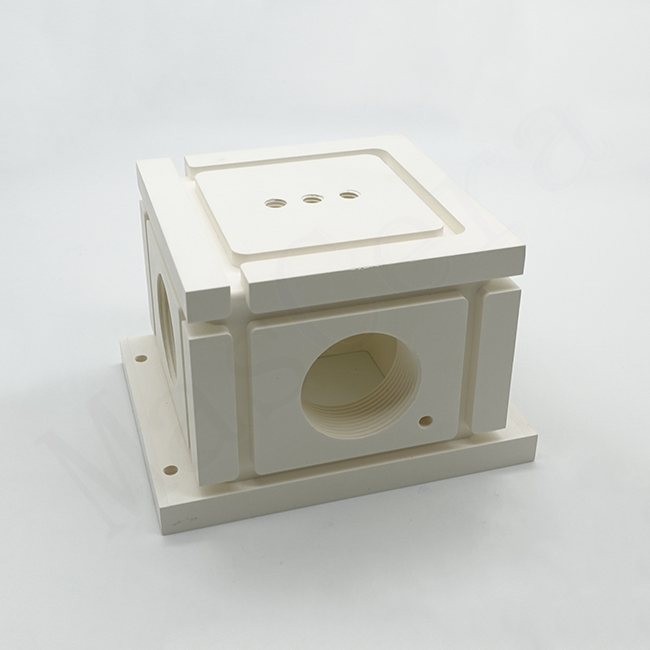

Boron nitride square crucible for sintering ceramic substrates

- MSJ/BN-012

- BN99 boron nitride ceramic

- customized

- 5 pcs per type

- Sintering ceramic substrates

boron nitride (BN) crucible offers advantages of low wettability, chemical stability, high-temperature stability, and good thermal conductivity in the sintering of aluminum nitride (AlN) and silicon nitride (Si3N4) substrates. These advantages provide a reliable, clean, and high-quality sintering environment, ensuring the substrates are sintered in optimal conditions and maintain the desired performance.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Hot pressed boron nitride (HBN) ceramic is an ideal ceramic material for metal smelting crucibles because it will not react with most molten metals and has good non-wetting properties, ensuring that the molten metals will not be polluted. Boron nitride crucibles of Mascera are mostly produced in high purity boron nitride ceramic (BN99 type), which has the lowest impurities. it offers advantages of low wettability, chemical stability, high-temperature stability, and good thermal conductivity in the sintering of aluminum nitride (AlN) and silicon nitride (Si3N4) substrates. These advantages provide a reliable, clean, and high-quality sintering environment, ensuring the substrates are sintered in optimal conditions and maintain the desired performance.

Main properties

High-temperature stability:The highest sintering temperature for AlN substrates is around 2000°C, and for Si3N4 substrates, it is around 1850°C. Both processes involve thermal shock at different temperature ranges. BN crucibles can withstand high temperatures up to 2100°C and exhibit similar thermal expansion coefficients to AlN and Si3N4, ensuring stability under high-temperature conditions.

Low wettability:BN ceramic has low wettability, meaning that molten materials are less likely to spread extensively on its surface and instead tend to form small spherical shapes. This reduces the contact area between the substrate material and the boron nitride crucible during sintering, minimizing adhesion and difficulties in removing the sintered substrates from the crucible.

Chemical stability:BN ceramic exhibits high chemical stability and does not react with or contaminate many materials. When sintering AlN and Si3N4 substrates, using BN crucibles allows direct contact with the substrate material without introducing impurities or altering the composition and properties of the substrates.

Good thermal conductivity:BN crucible have high thermal conductivity, facilitating efficient heat transfer. This helps achieve uniform heating and temperature distribution during the sintering process, enhancing sintering uniformity and quality. It also contributes to the uniformity of substrate density, structure, composition, and dimensional shape, resulting in improved electrical performance, durability, and precision dimensions for AlN and Si3N4 substrates.

Material Data Sheet

| Item | Unit | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E | BN-S |

|---|---|---|---|---|---|---|---|---|---|

Main Content | - | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN | BN+Si3N4 |

Color | - | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green | Dark Grey |

Density | g/cm3 | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 | 2.2-2.3 |

Flexural Strength | Mpa | 18 | 30 | 65 | 65 | 80 | 90 | 90 | 150 |

Compressive Strength | Mpa | 45 | 85 | 145 | 145 | 175 | 220 | 220 | 380 |

Thermal Conductivity | W/Mk | 35 | 40 | 35 | 35 | 45 | 30 | 85 | 40 |

Thermal Expansion Coefficient (@25 - 1000℃) | 10-6/K | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 |

Max. Service Temp. @Air Condition | ℃ | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. @Vacuum Condition | ℃ | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Max. Service Temp. @Inert Gas Condition | ℃ | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Electrical Resistivity | Ω.Cm | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 | >1013 |

Tips for Using

To maximize the life span of boron nitride crucible, operation under protective gas (Ar or N2) environment is strongly recommended.

Working temperature in the air should not exceed 900℃, oxidation will occur when more than 900°C.

The crucible shall be stored in the dry environment inside a sealed container.

Never wash the crucible with water. Use fine sandpaper or cloth to remove any dirts or residues.

Not suitable for the use with Sb2O3, chromium oxide, molybdenum trioxide, arsenic trioxide, titanium carbide, high lead glass glaze, boron phosphate, potassium phosphate, chlorine.

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |