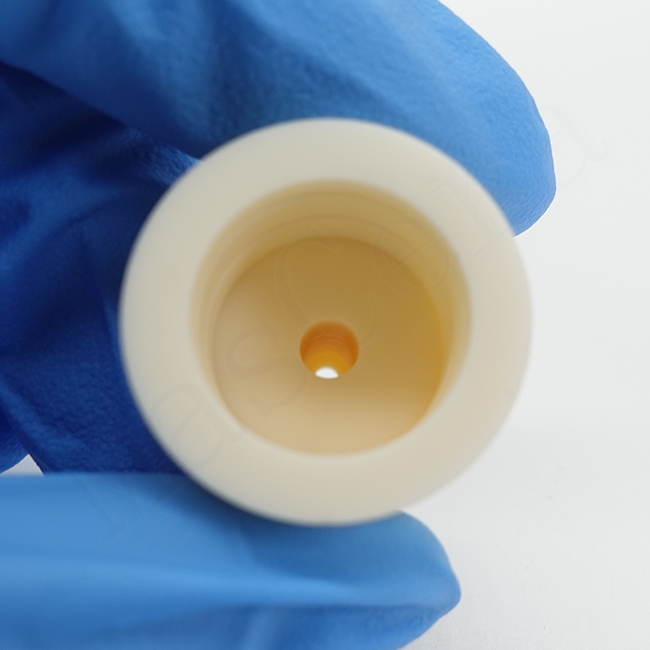

High Purity Alumina Ceramic Nozzles

- MSJ/AL-012

- Alumina Ceramic

- Customized

- 10 pcs per type

- Industrial Applications

The alumina ceramic nozzle is a high-performance industrial nozzle made from premium alumina ceramic material. It features excellent hardness, wear resistance, high-temperature resistance, and chemical stability. These nozzles are widely used in spraying equipment, liquid and gas delivery systems, the electronics industry, and machining processes, making them an ideal choice for demanding applications.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product Detail

The alumina ceramic nozzle is a high-performance industrial nozzle made from premium alumina ceramic material. It features excellent hardness, wear resistance, high-temperature resistance, and chemical stability. These nozzles are widely used in spraying equipment, liquid and gas delivery systems, the electronics industry, and machining processes, making them an ideal choice for demanding applications.

Xiamen Mascera Technology Co., Ltd. is an industrial nozzle manufacturer with over 10 years of production experience. Our high-purity alumina ceramic nozzles (95%, 99%, 99.5%, 99.8%) can last for several years depending on the usage environment and conditions. We offer customization services for alumina ceramic nozzles based on the specific needs of our customers. For more information, please contact us.

Performance Characteristics

High Hardness and Wear Resistance

Mohs hardness up to 9, effectively resisting wear, making it suitable for high-wear environments.

High-Temperature Resistance

Withstands temperatures up to 1300°C, maintaining stable performance in high-temperature environments.

Excellent Chemical Stability

Resistant to corrosion from acids, alkalis, and organic solvents, making it suitable for various chemical equipment applications.

Superior Insulation Properties

Excellent electrical insulation ensures safe use in electrical equipment.

Low Thermal Expansion Coefficient

Maintains dimensional stability during rapid temperature changes, ensuring process precision.

Material Data Sheet

Item | Unit | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | 99.8% Al2O3 |

Purity | % | 95 | 99 | 99.5 | 99.8 |

Color | - | White/Pink | Ivory | Ivory | Ivory |

Density | g/cm3 | 3.65 | 3.85 | 3.90 | 3.92 |

HV Hardness | - | >1300 | 1700 | 1750 | 1800 |

Fracture Toughness | Mpa.m1/2 | 3-4 | 3-4 | 4 | 4 |

Young’s modulus | Gpa | 320 | 340 | 370 | 390 |

Flexural Strength @25℃ | Mpa | 300 | 330 | 375 | 390 |

Compressive Strength@25℃ | Mpa | 2200 | 2350 | 2450 | 2500 |

Thermal Conductivity@25℃ | W/m.k | 18-22 | 27 | 29 | 32 |

Thermal Expansion Coefficient (25-1000℃) | 10-6mm/℃ | 8 | 8 | 8 | 8 |

Thermal Shock Resistance | △T(℃) | 220 | 180-200 | 180-200 | 180-200 |

| Max. Working Temperature | ℃ | 1500 | 1650 | 1700 | 1700 |

Dielectric Strength | kv/mm | 16 | 20 | 22 | 22 |

Electrical Resistivity@25℃ | Ω.cm | 1014 | 1014 | 1014 | 1014 |

Dielectric Constant (@1MHz, 25℃) | - | 9 | 9.7 | 9.7 | 9.8 |

Dielectric Loss | - | 0.0004 | 0.0002 | 0.0002 | 0.0001 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |