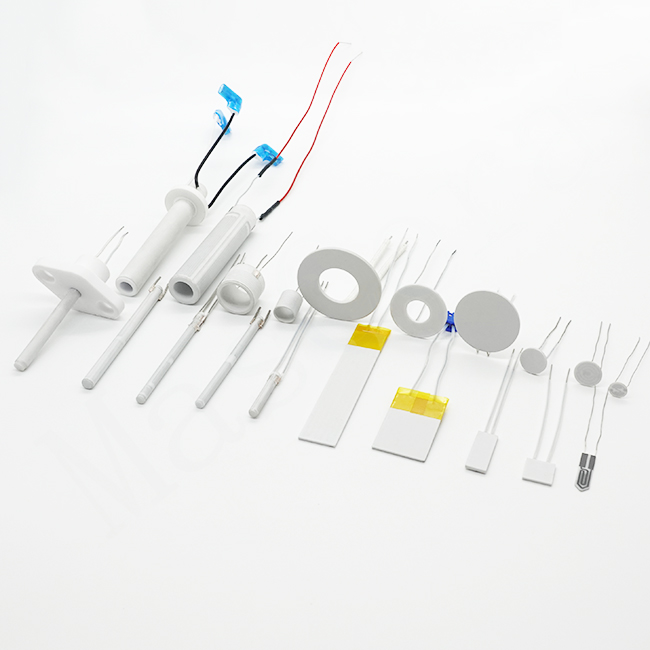

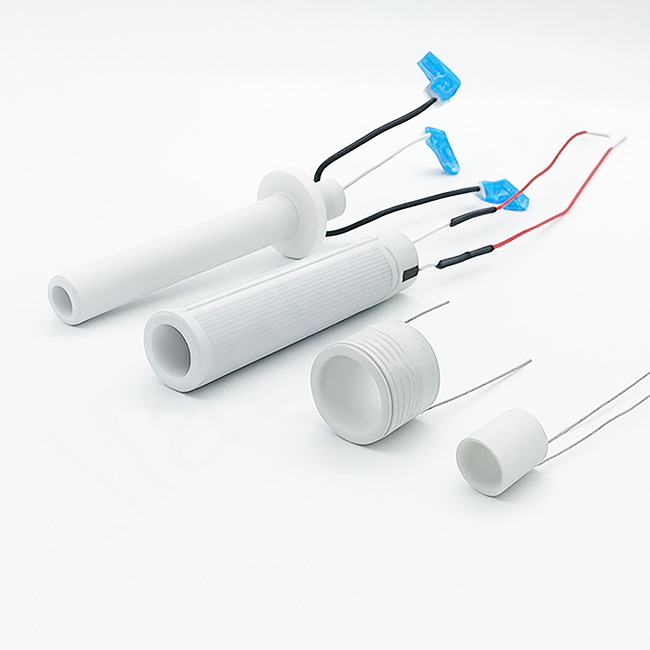

MCH Ceramic Heater for Small Home Appliances

- MSJ/AL-017

- Alumina Ceramic

- customized

- 100

- Small Home Appliances

Ceramic Heater features rapid heating, high power density, long service life, and environmental safety.It is widely used in medical devices, 3D printers, beauty and hair tools, automotive preheating systems, electronic cigarettes, and household heating appliances.Compared with PTC heaters, the MCH Ceramic Heater provides up to 30% higher energy efficiency with stable performance.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product Detail

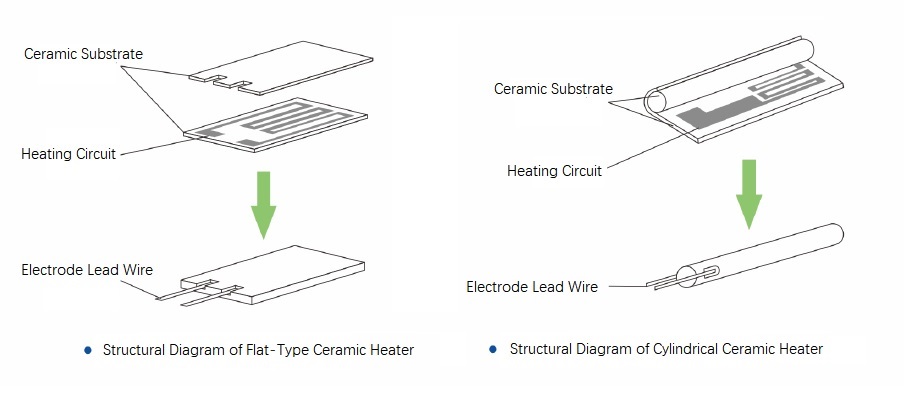

The MCH Ceramic Heater (Metal Ceramic Heater) is an advanced heating element made by printing high-melting-point metal paste (tungsten or molybdenum manganese) on a alumina ceramic substrate (Alumina Ceramic Heater).

After hot-press lamination and co-firing at around 1600 °C in a reducing atmosphere, the metal and ceramic are sintered together to form a fully integrated Ceramic Heating Element with excellent insulation, uniform temperature distribution, and fast thermal response.

This type of Ceramic Heater features rapid heating, high power density, long service life, and environmental safety.It is widely used in medical devices, 3D printers, beauty and hair tools, automotive preheating systems, electronic cigarettes, and household heating appliances.Compared with PTC heaters, the MCH Ceramic Heater provides up to 30% higher energy efficiency with stable performance.

Key Features

High Efficiency and Energy Saving

The MCH Ceramic Heater achieves high power density and superior thermal efficiency, reaching the target temperature within seconds. Its compact structure ensures fast, efficient heating suitable for various sizes and forms of small home appliances.

Corrosion & Heat Resistance

As chemically stable Wear Resistant Ceramic materials, both alumina and steatite resist acid, alkali, moisture, and high temperatures. The Ceramic Grinding Core maintains performance even in hot or humid grinding environments, ensuring food flavor integrity.

Safe and Environmentally Friendly

The alumina ceramic body provides excellent insulation and dielectric strength. The surface remains electrically safe and flameless during operation, producing no harmful emissions and meeting RoHS environmental standards.

Silent Operation

The heating process is free from arcing or electromagnetic interference, ensuring quiet and stable performance—ideal for compact and smart household appliances.

Main Properties

| Item | Properties |

Appearance | Clean, smooth surface without defects |

| Lead Wire Pull Strength(Vertical direction) | ≥ 2 kgf |

| Lead Wire Pull Strength(Horizontal direction) | ≥ 3 kgf |

| Operating Temperature Range | -50°C ~ 800°C |

| Normal Working Surface Temperature | 150 ~ 250 °C |

| Maximum Continuous Operating Temperature | 500°C |

| Resistance | Tested under 25 ± 1 °C, tolerance ±10 % Ω |

| Insulation Strength | Apply AC 1800 V for 1 second, leakage current ≤ 5 mA |

| Temperature Coefficient of Resistance | 3800 PPM/°C |

Structure and Dimensions

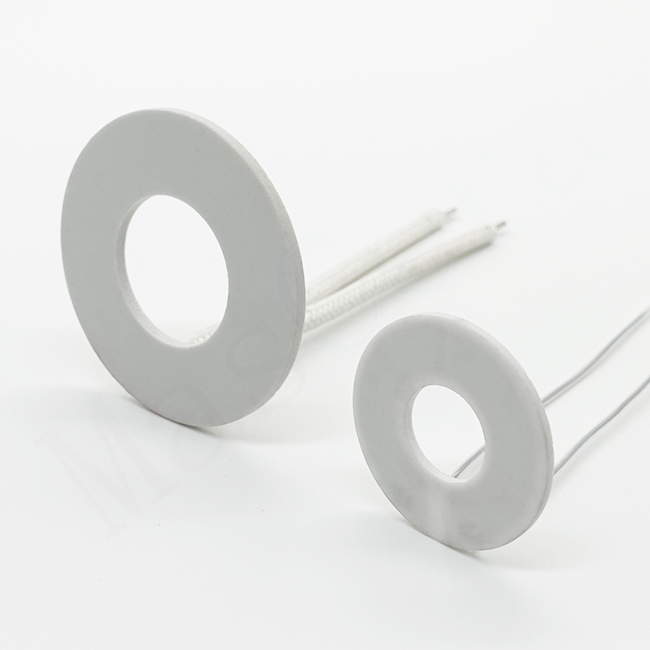

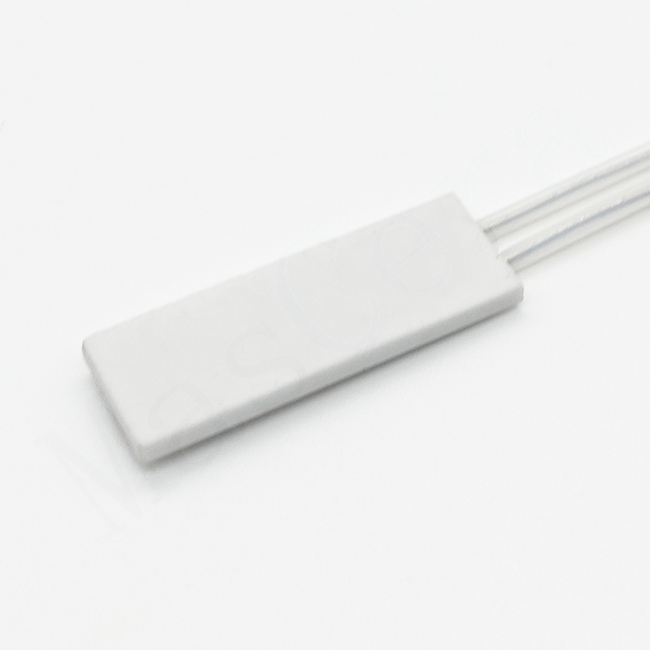

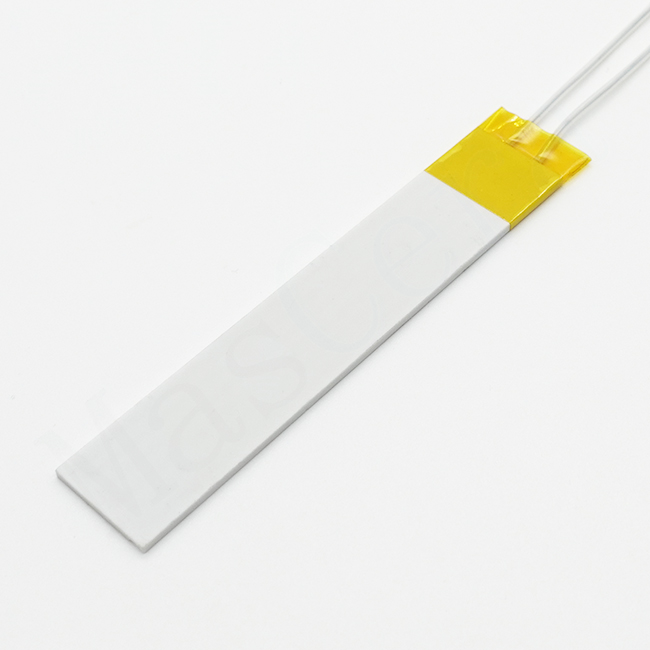

Mascera mainly produces alumina ceramic heating elements in flat and cylindrical types.

Dimensions and Tolerance Range

| Shape | Size(mm) | Tolerance | ||

| Length | Width | Thickness | ||

| Flat | 100max | 100max | 0.6~2.0 | Length ±1% Width ±2% Thickness ±5% |

| Shape | Outer Diameter | Length | Tolerance | |

| cylindrical | Ø3~Ø20 | 90max | Diameter ±2% Length ±1% | |

Application

Mascera's alumina ceramic heating elements are widely used in:

Instant water heaters, coffee makers, air purifiers, dryers, microwave ovens.

Hair straighteners, curlers, beauty devices, infrared physiotherapy heaters.

IV fluid heaters, sterilizers, analytical instruments.

Soldering stations, 3D printers, glue guns, air heaters, drying systems.

Engine preheating systems, air-conditioning heaters.

E-cigarettes, aromatherapy diffusers, cigarette lighters.

Why Mascera

With decades of expertise in advanced ceramics, Mascera is your trusted partner for high-performance MCH Ceramic Heater solutions.Our Metal Ceramic Heater components, made from premium Alumina Ceramic, deliver exceptional efficiency, precision, and reliability for modern heating systems.

We provide:

Advanced co-firing and sintering process for stable and consistent Ceramic Heating Elements

Fast and uniform heating with superior thermal efficiency

Safe, energy-saving performance with excellent insulation strength

Proven reliability in small home appliances, medical devices, and industrial systems

Competitive pricing, customized designs, and flexible production volumes

Contact us today to discover how Mascera's MCH Ceramic Heater technology can enhance your products with faster heating, longer lifetime, and outstanding energy efficiency.