Silicon Nitride Ceramic Plate For Welding Positioning

- MSJ/SN-009

- Silicon Nitride

- customized

- 10 pcs per type

- industrial applications

Silicon nitride ceramic, with the chemical formula Si3N4, is a significant structural material known for its excellent overall performance. It boasts impressive properties such as high flexural strength, fracture toughness, wear resistance, and thermal shock resistance, positioning it as one of the top-performing fine ceramics. Silicon nitride ceramic exhibits exceptional temperature resistance, maintaining its mechanical strength even at high temperatures of up to 1200 ℃. At Mascera, we specialize in machining silicon nitride ceramics to achieve precise dimensions and a smooth surface finish, customized according to customer's specific design and requirements.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Silicon nitride ceramic, represented by the chemical formula Si3N4, is a vital material in the field of structural ceramics due to its exceptional overall performance. It exhibits impressive properties including high flexural strength, fracture toughness, wear resistance, and thermal shock resistance, positioning it as one of the top-performing materials among fine ceramics. Silicon nitride ceramic showcases remarkable temperature resistance, as its mechanical strength can be maintained even at temperatures as high as 1200 ℃. Moreover, it resists infiltration and corrosion from various molten metals and alloys, such as aluminum, lead, tin, silver, brass, nickel, and more.

Silicon nitride ceramic, represented by the chemical formula Si3N4, is a vital material in the field of structural ceramics due to its exceptional overall performance. It exhibits impressive properties including high flexural strength, fracture toughness, wear resistance, and thermal shock resistance, positioning it as one of the top-performing materials among fine ceramics. Silicon nitride ceramic showcases remarkable temperature resistance, as its mechanical strength can be maintained even at temperatures as high as 1200 ℃. Moreover, it resists infiltration and corrosion from various molten metals and alloys, such as aluminum, lead, tin, silver, brass, nickel, and more.

Benefiting from the excellent comprehensive performance, silicon nitride ceramic can be used in many severe mechanical, thermal, chemical, wear applications, it will greatly improve the reliability, performance and working life of workpieces, reducing the frequency and cost for replacement.

After sintering, silicon nitride ceramic exhibits exceptional hardness, necessitating machining with diamond tools. At Mascera, we possess the capability to machine silicon nitride ceramics with precision, resulting in smooth surfaces and high dimensional accuracy tailored to our customers' designs. Whether you require prototyping or bulk orders, we are dedicated to becoming your trusted partner for technical ceramic parts.

Main properties of silicon nitride ceramic

High mechanical strength remains up to 1200℃

High fracture toughness

Extremely high hardness

Outstanding wear resistance and good self-lubricating property

Low thermal expansion

Excellent thermal shock resistance which can withstand sudden temperature change

Good resistance to acid&alkali and oxidation

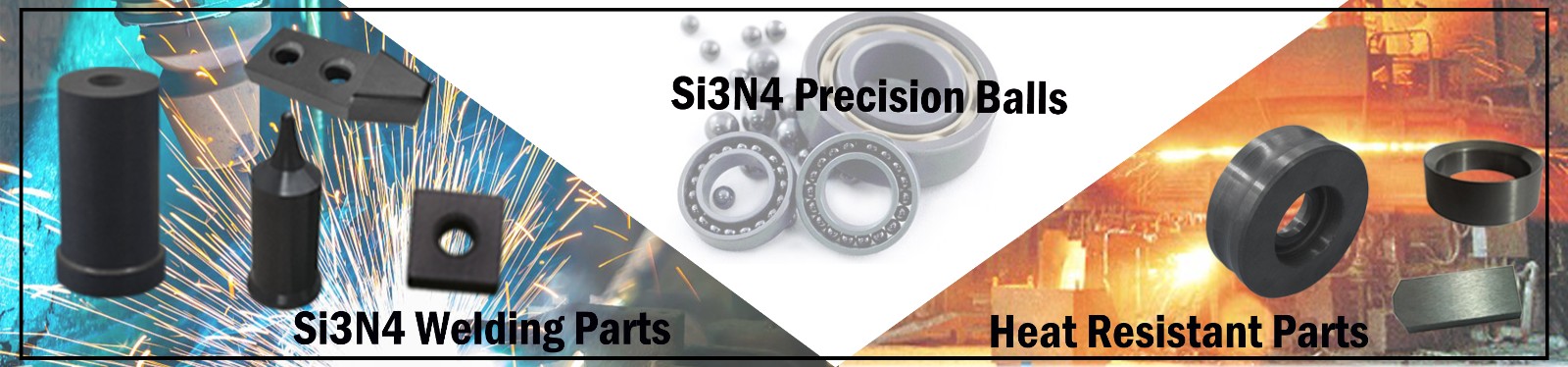

Typical applications of silicon nitride ceramic

Bearing balls and rollers

Cutting tools

Valves, turbocharger rotors for engines

Turbine blades

Diesel engine glow plugs

Molten metal handling

Thermocouple sheaths

Welding jigs and fixtures

Welding nozzles

Material Data Sheet

| Item | Unit | Technical parameters |

| Purity | % | 95 |

| Color | - | Black |

Density | g/cm³ | ≥3.2 |

| Hardness (HV) | Mpa | 1500 |

| Young's Modulus | Gpa | 300 |

Fracture Toughness | Mpa.m1/2 | 6.2 |

Flexural Strength@25℃ | Mpa | >720 |

Compressive Strength@25℃ | Mpa | 2200 |

Thermal Conductivity@25℃ | W/mk | 15-20 |

Coefficient of Thermal Expansion (25-1000℃) | 10-6/℃ | 3.0-3.2 |

| Poisson Ratio | - | 0.26 |

| Max. Working Temperature | ℃ | 1200 |

| Dielectric Strength | Kv/mm | 16 |

Electrical Resistivity@25℃ | Ω.cm | >1014 |

Dielectric Constant (@1MHz, 25℃) | - | 8.2 |

Dielectric Loss (Tan Delta) (@1GHz, 25℃) | - | 0.004 |

Available shapes of silicon nitride ceramics

Ceramic rod / ceramic pin / ceramic plunger

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic ball

Ceramic piston

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |