Snap Off Utility Knife Ceramic Replacement Blades

- MSJ/CCB-001

- zirconia ceramic

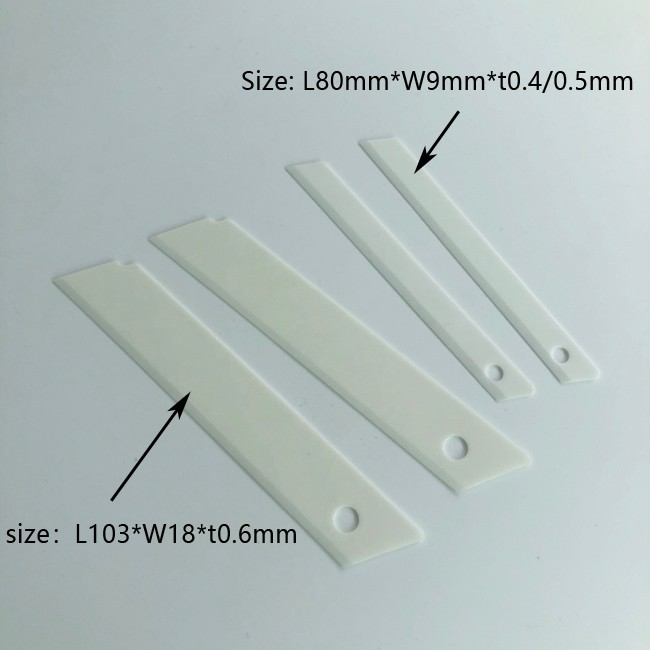

- 103*18*t0.6mm, 80*9*t0.4/0.5mm

- 100 pcs per type

- utility knives

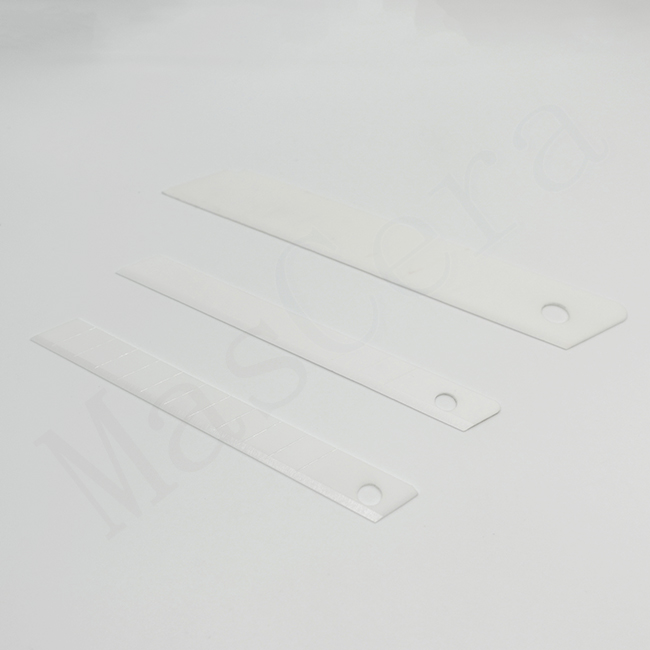

Our snap off ceramic blades are replacement blades for common snap off utility knives, there are two sizes of blades, big one (width 18mm) is for big snap off utility knives, small one (width 9mm) is for small snap off utility knives. There are snap off lines on the bodies of ceramic blades, when the tips are broken or worn, you could break off it and continue to use.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Ceramic blades made of zirconia ceramic have very high hardness and good wear resistance, corrosion resistance, it will never rust like metal blades, the sharp cutting edge will keep very long time, it will reduce the replacement frequency and improve efficiency of cutting works. Therefore, zirconia ceramic has wider and wider application for ceramic utility blades or ceramic replacement blades of cutting tools. It shows excellent performance in cutting paper, carboard, fiber, aluminum foil , plastic film, adhesive tap, rubber, cloth, rubber etc.

Our snap off ceramic blades are replacement blades for common snap off utility knives, there are two sizes of blades, big one (width 18mm) is for big snap off utility knives, small one (width 9mm) is for small snap off utility knives. There are snap off lines on the bodies of ceramic blades, when the tips are broken or worn, you could break off it and continue to use.

Mascera provides custom manufacturing for zirconia ceramic blades in your required sizes or thickness, the thinnest ceramic blades we have made is 0.2mm, the angle of cutting edge can also be machined as per your requirement. To provide a short lead time and fast delivery, we always make stocks for some standard ceramic blades, welcome to contact us when you have interest in our ceramic blades.

Ceramic blades we are providing:

Ceramic blades for snap off utility knives

Surgical ceramic blade

Ceramic blade for capsule trimming

Ceramic blade for cloth cutting

Ceramic blade for carpet cutting

Ceramic blade for plastic film slitting

Deburring ceramic blade

Comparing to traditional metal cutting blades, ceramic blades have several advantages:

Sharpness of cutting edge will remain 60 times longer than steel blades

Never rust like metal blades

Non-magnetic and non-electrostatic

Good corrosion resistance to acids and alkali

Good electrical insulation

High temperature resistance

Material Data Sheet

| Item | Unit | Technical Parameters |

|---|---|---|

| Stabilizer | - | Y2O3 |

| Color | - | white |

Density | g/cm3 | 5.95-6.05 |

Hardness(HV 0.5) | - | 1300 |

Fracture Toughness | Mpa.m1/2 | 7 |

Flexural Strength (@R.T.) | Mpa | 900 |

Compressive Strength (@R.T.) | Mpa | 2200 |

Thermal Conductivity (@R.T.) | W/m.k | 2.2 |

Thermal Shock Resistance | △T(℃) | 280-350 |

Thermal Expansion Coefficient(@R.T.) | 10-6/℃ | 10.3 |

| Max. Working Temperature (@R.T.) | ℃ | 850 |

Instruction for Using Snap Off Ceramic Blades

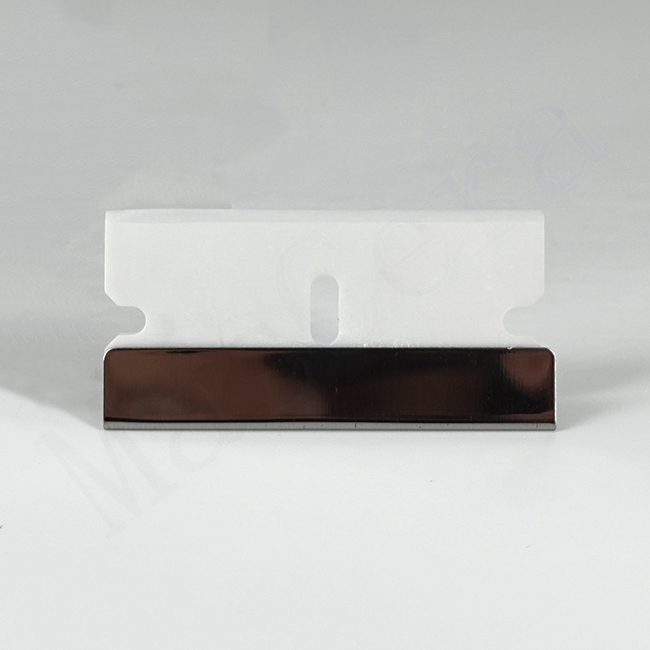

1. Make sure the ceramic blade is installed in knife holder properly, never hold the ceramic blade to cut without a knife holder.

2. Don’t face the cutting edge toward people and take away fingers or hands from cutting direction when cutting work.

3. Never release the ceramic blade too long from knife holder when cutting, it is easy to break when the length is too long.

4. Never use ceramic blade to cut unsuitable material to avoid hurt of unexpected break.

5. Keep your mind focus in the cutting work to avoid unexpected hurt.

6. The ceramic blade should be retracted inside the holder completely after cutting work.

7. Wear gloves and use proper tools to break the blunt segment when cutting edge is no longer sharp, never break the blade with bare-hand and take attention to unexpected hurt by fragment spatter.

8. Never put the knife in your clothes pocket to avoid unexpected hurt.

9. The waste knife blade should be packed well before discard.

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a China supplier which specialized in custom manufacturing of technical ceramic components. We provide a broad range of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride ceramic, silicon carbide ceramic, boron nitride ceramic and aluminum nitride ceramic.

We have completed production lines for molding, sintering, high precision machining, quality inspection of technical ceramic components. Our products are in conformity with ISO9001:2015 quality management system and we are capable to deliver ceramic components of fully dense, accurate size and surface finish control, prompt lead time.

Since our foundation, Mascera has committed to providing ceramic components of highest quality and has built faithful partnership with our customers. Currently, our products have been exported to 40 countries and widely applied in industries like machinery, automotive, chemistry, medical, energy, electronic, semiconductor, aerospace, telecommunication etc.

With expertise of material properties and machining technique, Mascera is able to give our customers the most valuable solutions for their specific applications and cooperate from prototype development to mass production. It is our honor that our technical ceramics components are used by some research institutes and high-tech enterprises, and make small contribution for technology innovation.