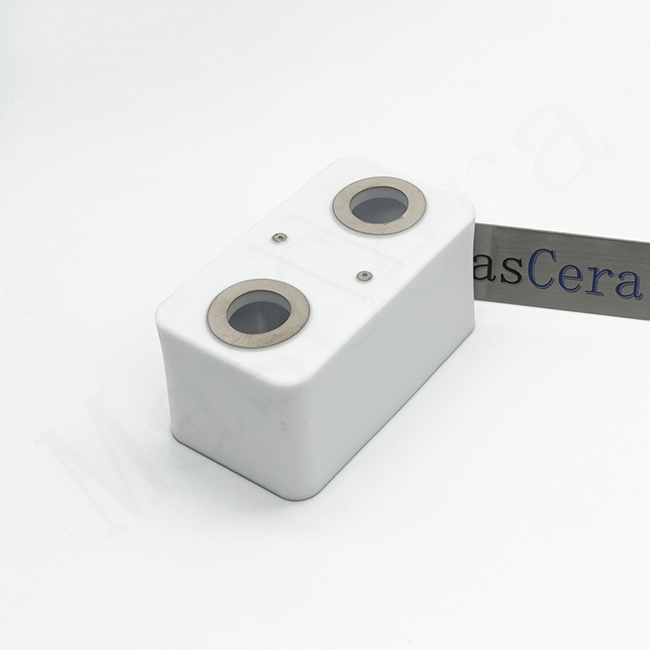

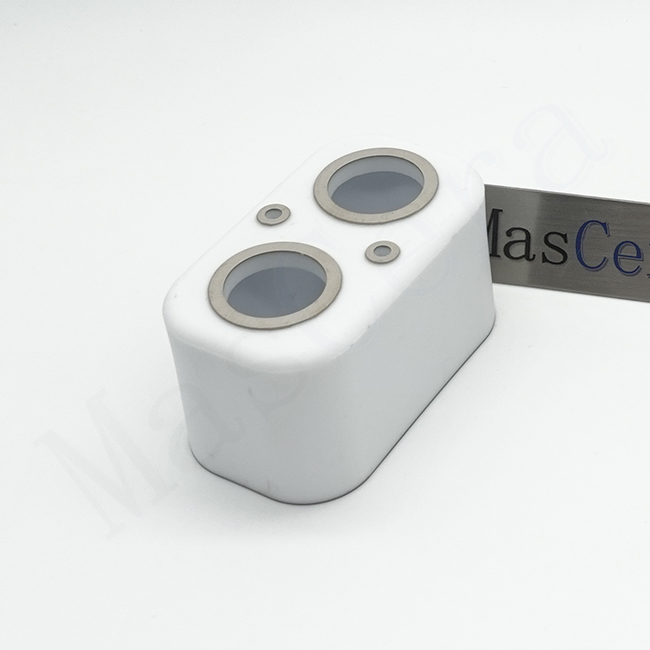

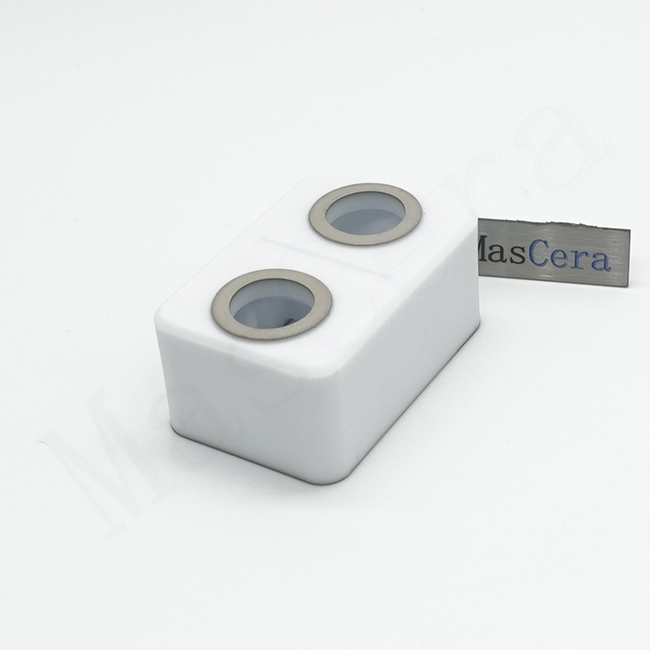

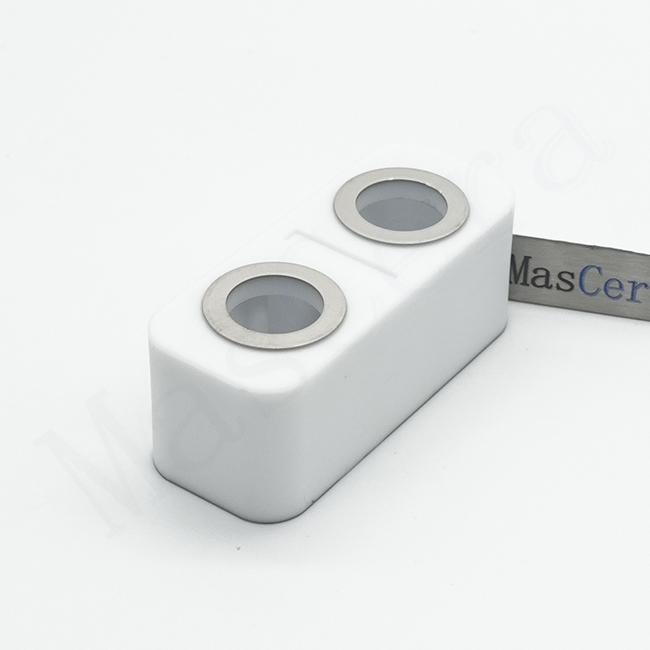

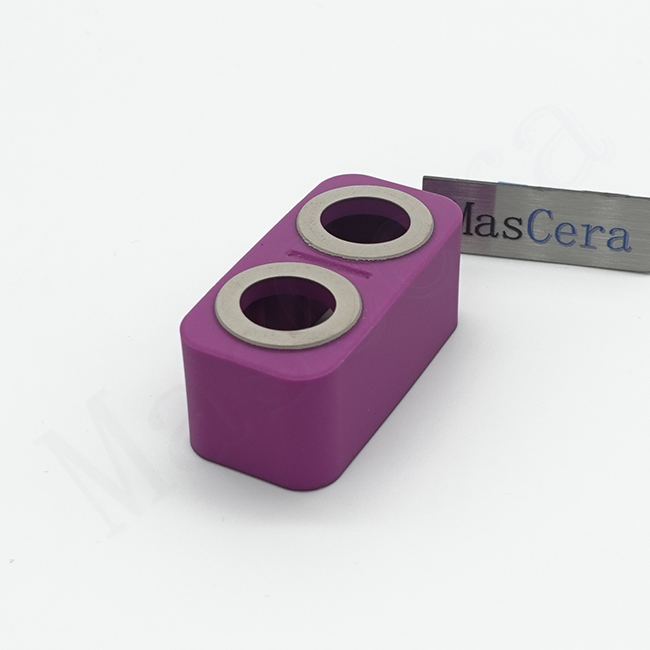

Al2O3 Alumina Ceramic Vacuum Relay Casing

- MSJ/AL-011

- 96% alumina ceramic

- customized

- 100pcs

- Electronic components

This product is produced using 96% aluminum oxide combined with nanometallization technology and is suitable for soldering to different materials such as copper and aluminum. It is widely used in vacuum electronic components, hermetic sealing of components such as thyristors, and electrode leads for vacuum equipment or sealed containers.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Aluminum oxide ceramics have excellent high-frequency dielectric properties, high-temperature resistance, corrosion resistance, do not melt under the influence of electric arcs, exhibit good electrical insulation properties, and can achieve vacuum tightness. They are an ideal insulating material for manufacturing high-voltage, high-current electronic components.

After metallization with nickel on the ceramic surface, aluminum oxide ceramics can be soldered to metals using Ag-Cu alloys or pure Ag and pure Cu solder, creating high-strength and hermetic connections, creating a vacuum environment. This protects electronic components for safe operation in high-voltage environments, reduces damage to relay contacts, and extends the lifespan of relays.

This product is produced using 96% aluminum oxide combined with nanometallization technology and is suitable for soldering to different materials such as copper and aluminum. It is widely used in vacuum electronic components, hermetic sealing of components such as thyristors, and electrode leads for vacuum equipment or sealed containers.

Critical parameters:

Gas leakage coefficient(Pa.m³/s): ≤10^-8

Volume resistivity(Ω.cm): ≥10^15

Combined strength(MPa): ≥60

Operating temperature(℃): 600~1000

Material Data Sheet

Item | Unit | 95% Al2O3 |

Purity | % | 95 |

Color | - | White/Pink |

Density | g/cm3 | 3.65 |

HV Hardness | - | >1300 |

Fracture Toughness | Mpa.m1/2 | 3-4 |

Young’s modulus | Gpa | 320 |

Flexural Strength @25℃ | Mpa | 300 |

Compressive Strength@25℃ | Mpa | 2200 |

Thermal Conductivity@25℃ | W/m.k | 18-22 |

Thermal Expansion Coefficient (25-1000℃) | 10-6mm/℃ | 8 |

Thermal Shock Resistance | △T(℃) | 220 |

| Max. Working Temperature | ℃ | 1500 |

Dielectric Strength | kv/mm | 16 |

Electrical Resistivity@25℃ | Ω.cm | 1014 |

Dielectric Constant (@1MHz, 25℃) | - | 9 |

Dielectric Loss | - | 0.0004 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Why Choose Us

10+ years experience in technical ceramics manufacturing and R&D

ISO9001:2015 certificated quality control management system

Different types of ceramic materials are provided for your different applications

Products have been exported to 40+ countries and have good reputation from our customers

MOQ is low, both prototype and bulk order will keep high quality

Any of your inquiries or questions will be responded no longer than 24 hours

Rigorous production plan to ensure on-time delivery