Reaction Bonded Silicon Carbide burner tubes for industrial furnace

- MSJ/SC-007

- Silicon Carbide

- Customized

- 10 pcs per type

- Industrial furnace

High-temperature furnace tubes produced from reaction-bonded silicon carbide (SiSiC) can be used up to 1250 degrees Celsius. With a resistance to cracking and an extended lifespan, they are ideal for kiln applications. These tubes are widely employed in industrial furnaces with both direct fire heating and indirect heating systems utilizing radiant tubes. Mascera can customize reaction-bonded burner tubes and nozzles according to customer requirements for high-temperature furnaces.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

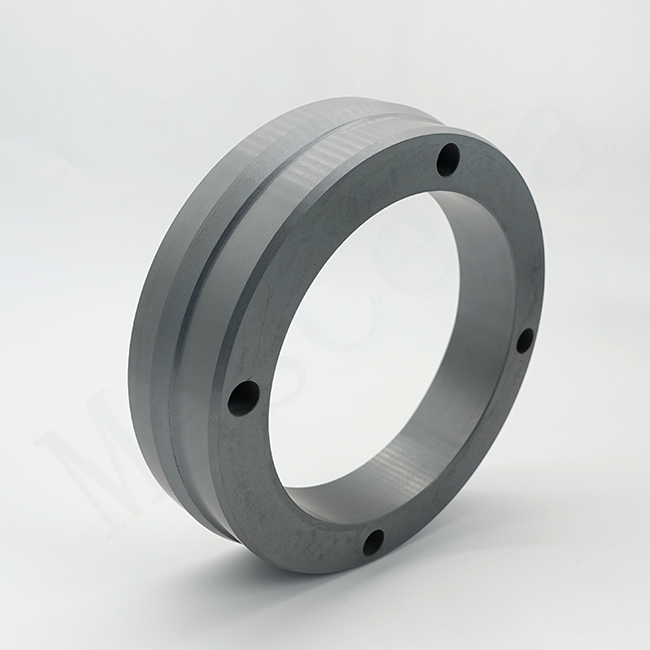

Product detail

Reaction-bonded silicon carbide (SiSiC) exhibits outstanding wear resistance, impact resistance, and chemical performance, with a usage temperature of up to 1250 degrees Celsius. It successfully addresses the thermal shock sensitivity issue observed in tubes made from mullite and other ceramic materials. SiSiC's mechanical properties at high temperatures surpass those of heat-resistant alloys, particularly in terms of strength, creep stress, and thermal oxidation, allowing for a net heat flux of up to 110 Btu/hr per square inch (50 kW/m2). These tubes can be utilized in furnaces with zone temperatures reaching 1250 degrees Celsius. In comparison, alloy tubes are typically used for heat fluxes of 60 Btu/hr per square inch (27 kW/m2) and lower, with a maximum furnace usage temperature of approximately 1100 degrees Celsius. Reaction-bonded silicon carbide can be shaped into various forms, including cone and sleeve shapes, as well as more complex engineered parts designed for equipment involved in raw material processing. This makes it suitable for applications in large ceramic combustion tubes and nozzles.

Main properties

High Usage Temperature

Chemical and Impact Resistance

Corrosion Resistance

Smooth Inner Wall

Excellent Wear Resistance

Lighter, Easy Installation

Extended Service Life

Cost-Efficient Maintenance

Material Data Sheet

| Item | Unit | Technical parameters |

|---|---|---|

| Materail | - | SiSiC |

| Color | - | Black |

| Density | g/cm3 | ≥3.03 |

| Apparent Porosity | % | <0.2 |

| Hardness (HV0.5) | - | 2000 |

| Modulus of Elasticity | Gpa | 350 |

| Fracture Toughness | Mpa.m1/2 | 2.5-3.5 |

| Flexural Strength @25℃ | Mpa | ≥350 |

| Compressive Strength @25℃ | Mpa | ≥2000 |

Thermal Conductivity @25℃ | W/Mk | ≥90 |

| Coefficient Of Thermal Expansion(25-1000℃) | 10-6/℃ | 4.0 |

| Thermal Shock Resistance | △T(℃) | 220 |

| Max. Working Temperature | ℃ | 1300 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |