High Temperature Al2O3 Alumina Ceramic Furnace Tube

- MSJ/HTCT-002

- 95% 99% 99.5% alumina ceramic

- customized

- 10 pcs per type

- high temperature furnace

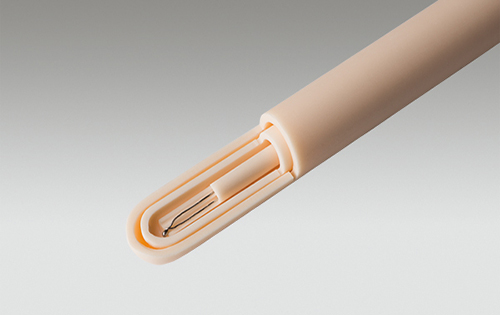

Alumina ceramic is widely applied in high temperature fields because of their good resistance to high temperature, it can withstand high temperature up to 1800℃, in addtion to its stable chemical properties, high mechanical strength and electrical insulation, Ceramic tubes made of alumina are commonly utilized in high-temperature furnaces, thermocouples' closed-end or multi-hole insulating rods, and corona electrode's square ceramic tubes.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Alumina tubes are commonly used in industrial applications that require high temperature resistance. Their exceptional durability has made them a preferred component in various industries, including furnace manufacturing, heat exchangers, laser tubes, and corona treater tubing.

The remarkable hardness, density, and strength of alumina ceramic tubing make it an excellent choice for processes involving aggressive or corrosive substances like mixed acids, bromine, and halogens. In the heat exchanger industry, its unique qualities enable it to effectively absorb and dissipate heat, providing protection for electrical coils and other equipment.

The outstanding durability of alumina ceramic tubing also makes it highly suitable for the heating industry. Heaters manufactured with alumina ceramic are safer than electric heaters as they can reach and maintain preset temperatures. Its resistance to high temperatures makes it an essential component in temperature measuring devices and temperature control equipment.

Mascera is able to produce ceramic tubes as long as 2000mm using the extrusion molding technology, custom size is available, please contact us when you have any demand.

Manufacturing Specification

Materail: 95% / 99% / 99.5% alumina ceramic (C795 / C799)

Available shape: round tubes, square tubes or custom shapes

Available size: Outer diameter 0.7-200mm, Inner diameter 0.3-190mm, length up to 2000mm

Usage of tubes:

1)thermocouple protection tubes(one end closed, single hole)

2)ceramic furnace tube (open both ends, single hole)

3)ceramic insulting rods for thermocouples (open both ends, single hole/double holes/four holes/multi holes)

4)square ceramic tubes for corona electrode

Product Feature

High mechanical strength and hardness

Extreme wear resistance

Good electrical insulation

Low dielectric constant and dielectric loss

Excellent corrosion resistance

Good resistance to high temperature

Material Data Sheet

Item | Unit | Technical Parameters |

Al2O3 purity | % | 99.5 |

Color | - | Ivory |

Density | g/cm3 | ≥3.8 |

| Moh's Hardness | - | 9 |

Water Absorption | % | ≤0.2 |

Flexural Strength (@R.T.) | Mpa | 340 |

| Compressive Strength(@R.T.) | Mpa | 2200 |

Thermal Conductivity (@R.T.) | W/mk | 25 |

Thermal Expansion Coefficient (25-1000℃) | 10-6/℃ | 7.6 |

| Continuous Working Temp. | ℃ | 1650 |

| Max. Working Temperature | ℃ | 1800 |

Dielectric Strength | Kv/mm | 22 |

Electrical Resistivity (@R.T.) | Ω.cm | 10 |

Dielectric Constant (1MHz, R.T.) | - | 9.7 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Why Choose Us

10+ years experience in technical ceramics manufacturing and R&D

ISO9001:2015 certificated quality control management system

Different types of ceramic materials are provided for your different applications

Products have been exported to 40+ countries and have good reputation from our customers

MOQ is low, both prototype and bulk order will keep high quality

Any of your inquiries or questions will be responded no longer than 24 hours

Rigorous production plan to ensure on-time delivery