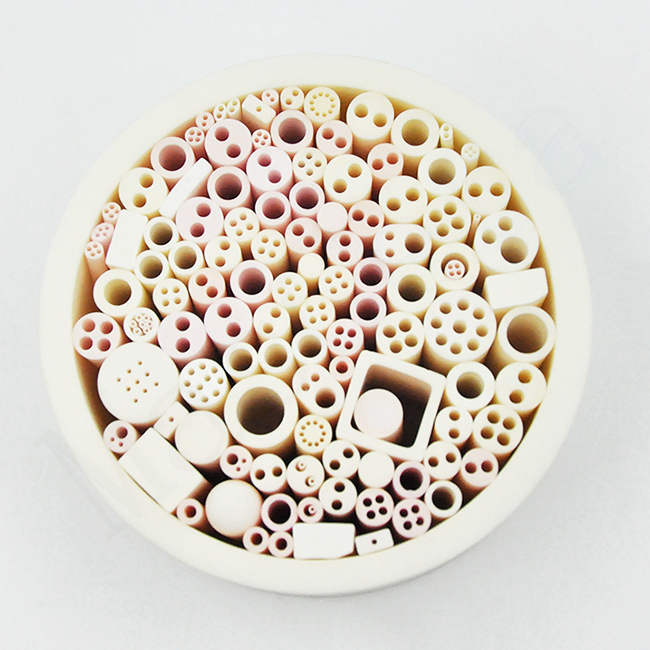

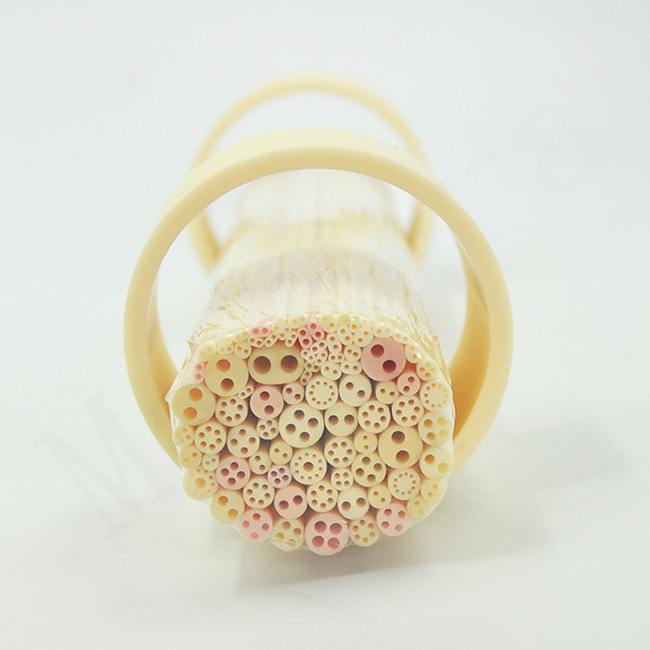

Single or Multi Bores Ceramic Thermocouple Insulator Tubes

- MSJ/HTCT-004

- 95% 99% 99.5% alumina ceramic

- 35 days after order

- 10 pcs per type

- 20000 pieces per month

Mascera is a professional supplier for technical ceramic parts, we provide custom manufacturing for alumina ceramics, zirconia ceramics, boron nitride ceramics, silicon nitride ceramics, silicon carbide ceramics, aluminum nitride ceramics and machinable glass ceramics.We produce alumina ceramic tubes for different usage, such as ceramic furnace tube, ceramic thermocouple protection tube, multi-hole ceramic tubes for thermocouple, ceramic square tubes for corona machines etc.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

When it comes to requiring protection, resistance, and durability, alumina, also known as aluminum oxide, is the top choice. Alumina's strength and resilience make it the preferred material for demanding conditions where resistance to deterioration and deformation is crucial. Alumina ceramic tubes possess a range of characteristics and features that make them highly suitable for various applications. This high-quality tubing exhibits exceptional hardness, excellent chemical resistance, long wear life, and outstanding insulation properties. Its diverse properties have made it a staple in industries that necessitate tubing capable of withstanding extreme temperatures.

The quality of an alumina tube relies on its purity, with higher purity levels resulting in greater resistance. Mascera Ceramics produces tubes with a purity factor of 95% or higher. The tubes can be shaped into various diameters to suit specific applications. Our alumina tubes exhibit high thermal conductivity and can endure significant compression.

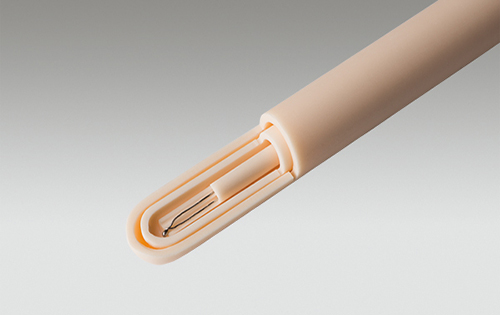

Thanks to its dielectric properties, an alumina tube is ideal for insulating electrical connections. The ceramic material's density provides protection against gas or liquid intrusion. With exceptional resistance to wear and abrasion, as well as its stability up to 1800℃, it ensures longevity and reliability. Once installed, it can withstand hazardous or hostile conditions without compromising performance.

Manufacturing Specification

Materail: 95% / 99% / 99.5% alumina ceramic (C795 / C799)

Available shape: round tubes, square tubes or custom shapes

Available size: Outer diameter 0.7-200mm, Inner diameter 0.3-190mm, length up to 2000mm.

Usage of tubes:

1)thermocouple protection tubes(one end closed, single hole)

2)ceramic furnace tube (open both ends, single hole)

3)ceramic insulting rods for thermocouples (open both ends, single hole/double holes/four holes/multi holes)

4)square ceramic tubes for corona electrode

Product Feature

High mechanical strength and hardness

Extreme wear resistance

Good electrical insulation

Low dielectric constant and dielectric loss

Excellent corrosion resistance

Good resistance to high temperature

Material Data Sheet

Item | Unit | Technical Parameters |

Al2O3 purity | % | 99.5 |

Color | - | Ivory |

Density | g/cm3 | ≥3.8 |

| Moh's Hardness | - | 9 |

Water Absorption | % | ≤0.2 |

Flexural Strength (@R.T.) | Mpa | 340 |

| Compressive Strength(@R.T.) | Mpa | 2200 |

Thermal Conductivity (@R.T.) | W/mk | 25 |

Thermal Expansion Coefficient (25-1000℃) | 10-6/℃ | 7.6 |

| Continuous Working Temp. | ℃ | 1650 |

| Max. Working Temperature | ℃ | 1800 |

Dielectric Strength | Kv/mm | 22 |

Electrical Resistivity (@R.T.) | Ω.cm | 10 |

Dielectric Constant (1MHz, R.T.) | - | 9.7 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Why Choose Us

10+ years experience in technical ceramics manufacturing and R&D

ISO9001:2015 certificated quality control management system

Different types of ceramic materials are provided for your different applications

Products have been exported to 40+ countries and have good reputation from our customers

MOQ is low, both prototype and bulk order will keep high quality

Any of your inquiries or questions will be responded no longer than 24 hours

Rigorous production plan to ensure on-time delivery